views

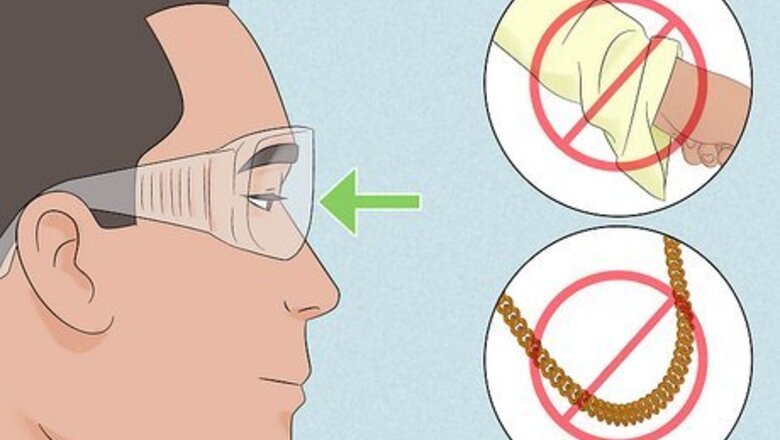

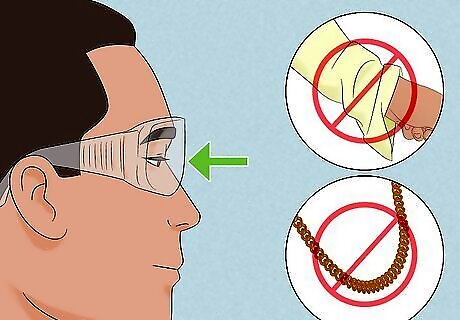

- Wear safety goggles or glasses that cover the sides of your eyes to protect them from flying debris.

- Drill a shallow pilot hole first. A pilot hole prevents the drill bit from slipping so you don't split or damage the wood.

- Choose the correct drill bit to drill the final hole. Using the wrong bit can cause the bit or the material you're drilling to break.

- Hold the drill steady and push it into the material you're drilling. If it takes more than light force to drill the hole, you're using the wrong bit.

Preparing to Drill

Wear safe clothing and eye protection. Avoid baggy clothing or dangling jewelry that could catch in the drill as you lean over it. Wear safety goggles or glasses that cover the sides of your eyes, to protect them from flying debris.

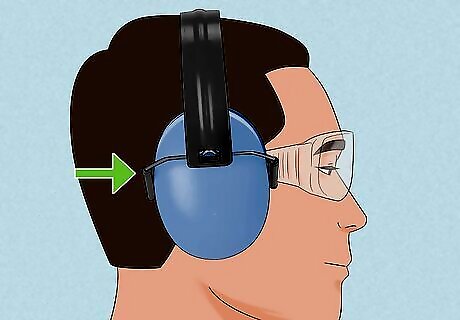

Wear ear protection if drilling regularly. A handheld electric drill produces about 90 decibels, which is just enough to cause hearing damage after prolonged exposure. Most cordless drills are quiet enough that hearing protection is not necessary. Impact drills (hammer drills) are the loudest handheld drills, producing over 100 dB. Hearing protection is recommended whenever using them.

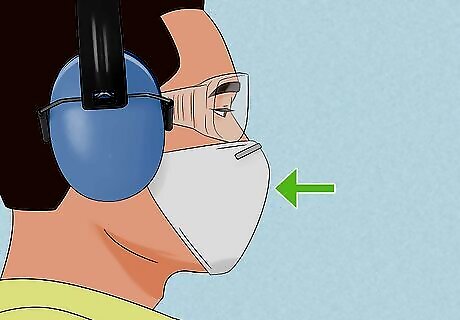

Protect your lungs when necessary. If the project kicks up a lot of dust, wear breathing protection. A dust mask is only good for short-term comfort. Use a respirator if you drill regularly or for long periods of time, or if the material you are drilling is a known respiratory hazard. Each respirator is rated for certain types of hazards. Make sure the one you use is suited to your project.

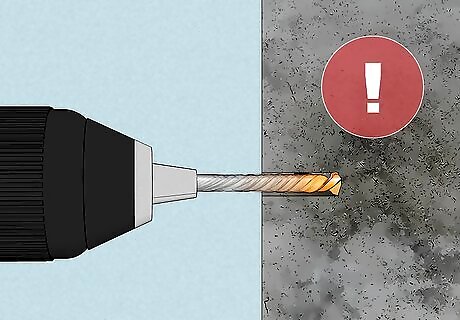

Choose the correct drill bit. Using a bit made from the wrong material can cause the bit or the material you're drilling to break. You can use a general-purpose bit on most wood; a masonry bit for stone, brick or concrete; an HSS (high speed steel) bit on most metals; and a carbide or diamond-tipped bit on very hard, brittle surfaces such as porcelain, glass, or glazed tiles. There are many specialized bit designs, so consult the drill manual or bit manufacturer if you're not sure which bit to use. When drilling a hole for a screw, there's an easy way to find the right size bit. Hold the screw up directly behind the bit. The bit should hide the shaft of the screw from view, but the screw threads should still be visible on both sides.

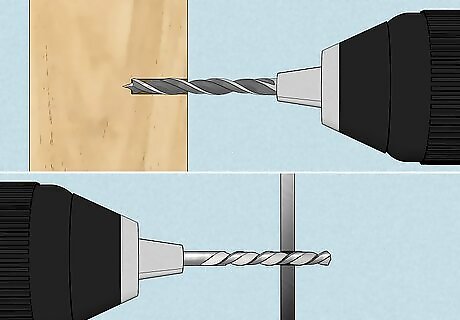

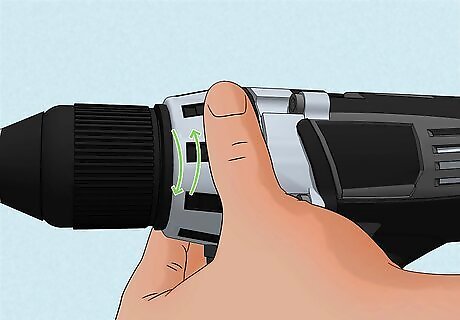

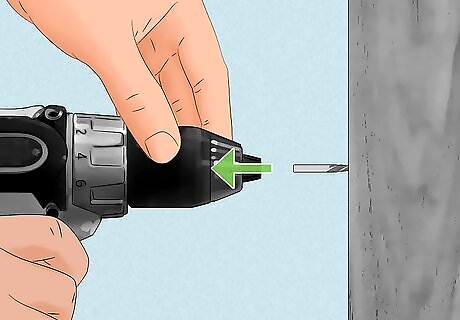

Fit the drill bit firmly into the chuck. The chuck is the clamp in the "jaws" of the drill. This holds the drill bit in place as it spins. To replace a drill bit, make sure the drill is off (and unplugged if corded), then loosen the chuck by rotating it. Depending on the drill, you may be able to do this by hand, or you may need a chuck key located in a compartment in the top or handle of the drill. Insert the drill bit into the chuck, then tighten again. Make sure the bit is straight and secure, and remove the key before you turn on the drill. With Dremel drills, you have to press a button next to the bit holder before removing the drill bit with the proper wrench. If you don't press this button, the bit will go around and around in circles instead of coming out. Each chuck has a maximum size. Most drills made for home use in the United States have a chuck of size 1/4", 3/8", or 1/2". The shaft of the drill bit must be smaller than this size (but the tip can be larger). Run the drill and watch the bit spin in the air. If it wobbles from side to side (or looks like a blurry cone), the bit is bent or not secured correctly. Discard bent bits, since they can easily break during drilling.

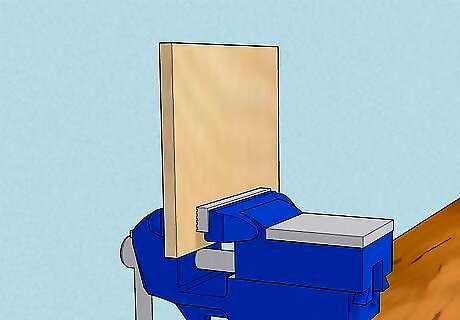

Clamp small pieces together. If you are drilling into a small, loose piece, clamp it down firmly before you drill. Do not hold the piece down with one hand while drilling, as the drill could slip and injure you.

Handle the cord safely. If the drill has a cord, never leave it stretched across a pathway when not in use. Never pick up the drill by the cord. If you are drilling in a wet or muddy area, use a cordless drill instead. If you need to plug the drill into an extension cord, check the drill manual for the minimum wire gauge (or go with 16 gauge if you're not sure). Do not chain multiple extension cords together, use indoor extension cords outdoors, or use an adapter to plug a three-prong cord into a two-prong outlet.

Drilling Safely

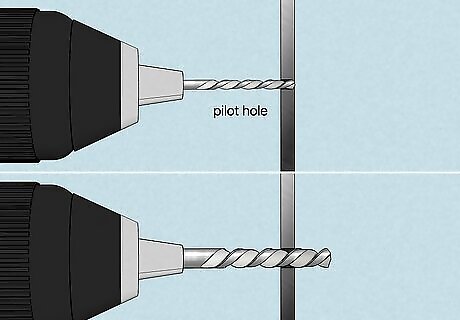

Drill a pilot hole. In many cases, you'll get better results if you start with a drill bit a little smaller than the final hole size. Drill a shallow "pilot hole," then switch to the larger bit to finish the job. The pilot hole will help prevent your drill bit from slipping, and reduces the chance of splitting wood or other damage. Very brittle materials such as ceramic and glass require extra care. Make a small "X" in masking tape where you want the hole, to help prevent slipping and chipping. Instead of drilling the pilot hole, place the drill bit over the X, then gently tap it with a hammer to create a small dent.

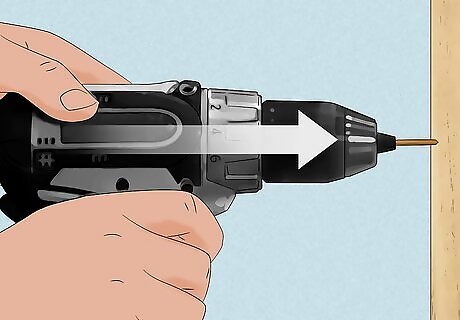

Drill with steady pressure. Hold the drill steady and push it into the material you're drilling. If it takes more than light force to drill the hole, you're probably using the wrong bit.

Adjust the clutch. Each drill has a twistable collar to adjust the torque, often with a series of numbers on it. The higher the number, the more torque (rotational force) the drill will apply. If you are having trouble penetrating the material, increase the torque. If you are over-driving screws (burying them too deep), or if drilling too deep could damage something, lower the torque. Some models mark the highest torque with a drill bit icon.

Avoid overheating the drill bit. If you are drilling through hard materials or drilling at high speeds, the drill bit will encounter an immense amount of friction. This can rapidly overheat the bit, to the point where it becomes red hot or burns the material you're drilling. Start at low drill speeds, and only increase the speed if the drill isn't moving smoothly. If you're drilling through hard materials, or drilling many holes in any material, stick to slow speeds and pause occasionally to give the bit a few seconds to cool down. When drilling glass, ceramic, or stone, give the bit a steady supply of water to keep it cool. One way to do this is to build a "dam" out of putty or modeling clay around your drilling area. Fill the area with water so it flows down into the hole. "Pump" the bit up and down so the water can reach the tip. Even if the drill bit doesn't look hot, give it time to cool down before touching it.

Do not force a jammed bit through. If the drill bit gets stuck in the material, don't try to force it out by running the drill. Unplug the drill, separate the bit and the chuck, and remove the bit using manual tools.

Comments

0 comment