views

Scoring and Snapping Thin Plexiglass

Lay the plexiglass flat on a work surface. For thin sheets of plexiglass that are up to ⁄16 inch (0.48 cm) thick, scoring the sheet and then snapping it is an easy way to cut it. Place the sheet down flat on a table or a work station so you can measure and cut on a stable surface. Make sure the surface is clean and clear of any objects that could impede your work or potentially mark or damage the sheet. Use an even and stable structure that doesn’t wobble.

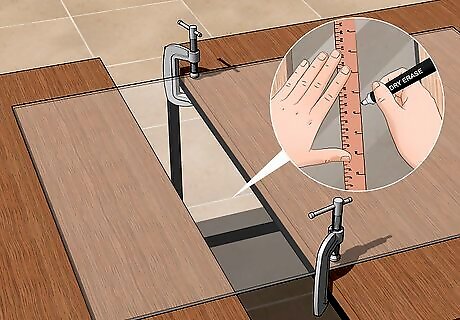

Draw a line with a dry-erase marker where you want to cut the board. With the sheet laid flat on the work surface, use a ruler as a guide and draw a straight line where you want to cut the sheet. Make the line visible and be careful not to smudge the marker. Use a dry-erase marker so you can erase it after you cut the sheet.Tip: If you make a mistake while you’re drawing the line, erase the mark fully so you can draw it again. Use a wet cloth or paper towel to remove the marker.

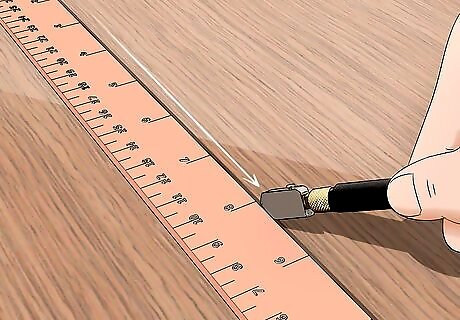

Use a utility knife to cut along the line you marked on the board. Make sure the sheet is flat and stable on the surface. Apply firm pressure and use a ruler to guide your utility knife as you drag it across the line you marked to score the sheet of plexiglass. Run the knife over the line 10 or 12 times, until you’ve made a deep groove in the sheet. You can also use a scoring tool to make your cuts if the blade is sharp enough to cut the plexiglass. The deeper you can make your cuts, the easier it will be to snap the board.

Flip the sheet over and score the other side. After you’ve formed a deep groove in 1 side of the plexiglass, grab the sheet by the sides and flip it over to expose the other side. Cut along the same line that you cut on the other side to further score the sheet. Score the plexiglass until you’ve formed a groove in the sheet. Be careful when you pick up the sheet so it doesn’t bend or warp before you’re ready to snap it.

Position the sheet so the portion that you cut is hanging over the edge. Once you’ve finished scoring the sheet, move it into a position that will make it easier for you to snap it off. Move the sheet so the portion that you plan to snap off is hanging over the edge. Be sure the entire portion that you plan to break off is hanging over the edge of the work surface.

Clamp the sheet in place to the surface. Use a spring or a C clamp and apply it to a part of the sheet that you don’t plan to cut. Apply the clamp so it’s attached to the sheet of plexiglass and the surface that you’re working on so the sheet doesn’t move. Be careful not to tighten the clamp so much that it puts a dent or divot in the sheet.

Snap off the cut portion of the plexiglass. With the sheet of plexiglass clamped in place on the work surface, apply quick, downward pressure to break off the piece that you cut. The sheet should break cleanly along the line that you scored in it. You can use 1 hand to brace the sheet while you push down on the sheet with the other hand. If the sheet doesn’t fully break along the line, use your utility knife to cut along the groove and break off the piece. Cut custom shapes using simple tools. "I needed to cut an odd shape out of plexiglass for my car window. Using just a utility knife, I scored the lines several times on both sides like the article said. Then I carefully snapped off the shape. It worked perfectly without any special tools!" - Sam K. Snap clean edges through patient scoring. "I tried using a jigsaw at first to cut plexiglass, but had better luck just scoring it repeatedly with a box cutter. It took time and patience, but once I had deep enough grooves, I could snap off clean edges. It's far easier than wrestling with power tools." - Carlos G. Understand techniques visually. "As a visual learner, I appreciated all the photos and illustrations demonstrating the step-by-step plexiglass cutting techniques. It's very helpful for understanding the process before attempting it myself." - David N. Feel empowered to DIY plexiglass projects. "I was intimidated by the thought of working with plexiglass until I came across this guide. It broke the process down using basic tools I already own. Now, I feel confident to take on some DIY projects requiring custom plexiglass pieces." - Peter W. Did you know that wikiHow has collected over 365,000 reader stories since it started in 2005? We’d love to hear from you! Share your story here.

Cutting Straight Lines with a Circular Saw

Use a circular saw with a carbide-tipped metal-cutting blade. Thicker sheets of plexiglass will need to be cut with a saw. Make sure the teeth of the blade are evenly spaced and the same size and shape for an even cut. A carbide-tipped blade that’s designed for cutting metal is strong enough to cut the sheet without any dust or debris flying off into the air. The fewer number of teeth on the blade will minimize the amount of dust or debris that cutting the plexiglass will produce. There are blades specially designed for cutting plexiglass that you can use as well.Warning: Small particles of plexiglass could damage your eyes. Wear eye protection when you cut the sheet.

Set the sheet down on a sawhorse mark where you want to cut. Place the sheet of plexiglass on a sawhorse so you can cut through the sheet while keeping it flat and secure. Use a straight edge or a ruler to mark a straight line on the sheet of plexiglass. This line will be your cutting guide so make sure it is straight and visible. Use a dry-erase marker so you can easily erase the markings if you need to make adjustments.

Align the cutting guide of the saw with the line you marked. The circular saw will have a viewer or a slot that allows you to see where the saw is lined up. Put this guide in line with the marking that you put on the sheet of plexiglass. Make sure the sheet is secure and doesn’t shake or move.

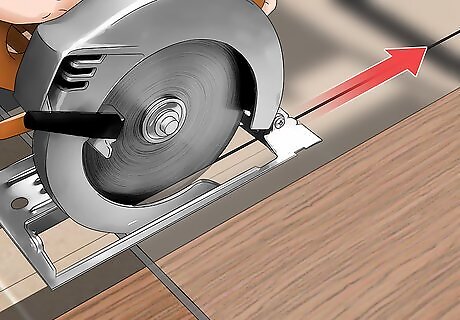

Bring the saw to full speed before cutting the sheet. The blade of the saw must be rotating at full speed before it makes contact with the sheet to create a smooth and even cut. Turn on the saw and allow it to rotate until it gets to its full speed. Cutting the sheet before the saw has reached full speed could cause the teeth of the blade to snag on the sheet and create a jagged or choppy cut.

Push the saw slowly and smoothly through the plexiglass sheet. Use the cutting guide and the straight line to guide the saw through the sheet. Push the saw at a steady and consistent pace to prevent the saw from jamming. If the saw is stuttering or catching, you may be pushing the saw too fast. Stop pushing to let the blade get back up to speed and then continue to push the blade through the sheet. Make sure the 2 halves are balanced on the sawhorse so they don’t fall to the ground when you finish cutting through the sheet.

Using a Jigsaw to Cut Shapes

Use a jigsaw to make rounded cuts in the plexiglass. A jigsaw looks a lot like a bandsaw but it’s shorter and cuts in an up-and-down motion. You can use a jigsaw to make straight cuts as well as rounded cuts so it’s a good option if you need to cut a specific shape or a circular piece out of a sheet of plexiglass. Use an uncoated blade with fine teeth to cut plexiglass. Keep a few extra blades nearby in case you need to replace it while you’re cutting.

Place the sheet of plexiglass flat on a sawhorse. Use a sawhorse as a work station to hold the sheet while you cut through it. Lie the sheet so it’s secure and stable on the sawhorse. Check to make sure the sheet doesn’t slide or wobble before you cut it.

Mark the sheet with a dry-erase marker to guide the jigsaw. It’s very important to have a guide to follow when you’re using a jigsaw, especially if the shape you are cutting is round or irregular. A jigsaw allows you to create a specific shape, but you need to have a good marking to use as a guide. Use a dry-erase marker to create the outline of the shape you plan to cut. A dry-erase marker makes it easier for you to erase the mark when you’re done or if you need to alter it.Tip: If you’re cutting a design or shape, use a stencil or a round object to help mark an even line.

Put on safety glasses to protect your eyes. Sawing a sheet of plexiglass can cause splinters and tiny particles to fly in the air. These could damage your eyes if they get in them. Before you begin sawing, put on a pair of safety glasses. Make sure the glasses fit securely on your head so they don’t fall off while you’re sawing!

Drill a hole to fit the jigsaw into the sheet. The jigsaw will need an opening to fit into the plexiglass sheet, so start by drilling a hole with a drill and masonry bit large enough to make a hole that the blade will fit through. If you plan to cut shape with twists and turns, drill holes through the sheet at the tightest corners of the shape. This will help the jigsaw blade turn when it gets to those turns. If the blade of the jigsaw isn’t able to take the turns easily, it could bend the blade or break it.

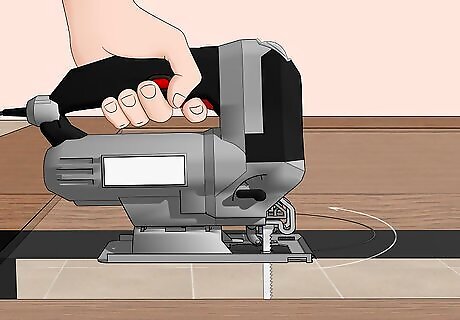

Insert the saw blade into the hole and bring the blade to full speed. Fit the blade of the jigsaw into the hole you made in the sheet and turn it on. A jigsaw blade moves slower than a band saw or a circular saw, so it must be brought to full speed before you start using it to cut. If the blade isn’t at full speed when it makes contact with the plexiglass, it could catch and bend or possibly break and damage your jigsaw. It’s possible the blade could snap and injure you, so use caution.

Push the jigsaw slowly to cut through the sheet. Apply steady pressure to keep the jigsaw from jumping off of the sheet. Follow your guide markings closely and slow down to take any turns. If you hear or feel the blade catching or stalling, slow down and back up to allow the blade to get back up to speed, then continue to push the saw through the plexiglass.

Comments

0 comment