views

Equipment Needed

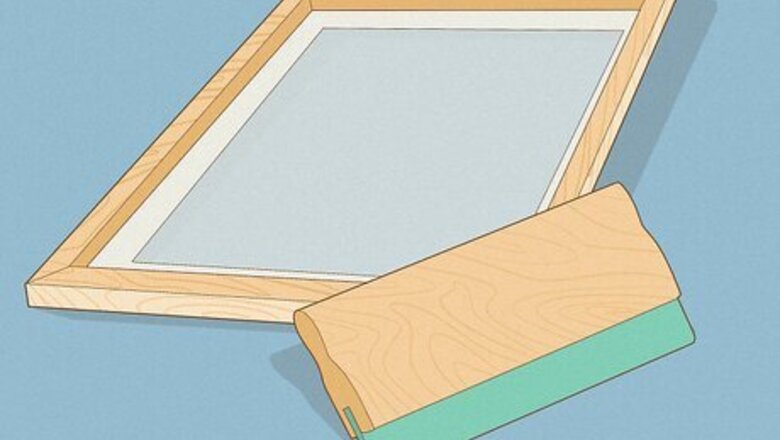

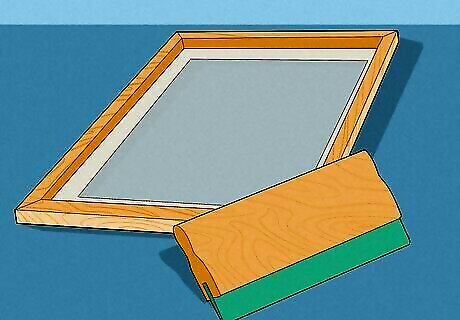

Screen printing supplies. You'll still need your basic screen printing supplies to start making screen print transfers. If you don't have the materials, you can buy them in a kit online or at many crafting stores. Another option is buying just a wood-framed screen (also called mesh) and a squeegee. You also may want transfer tape to help your vinyl stencil stick to your screen.

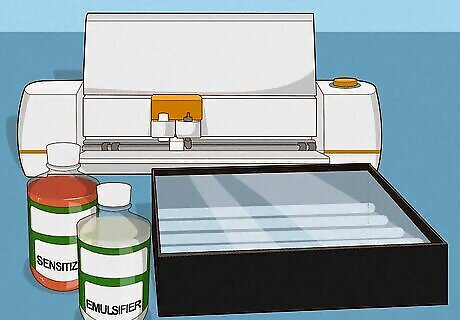

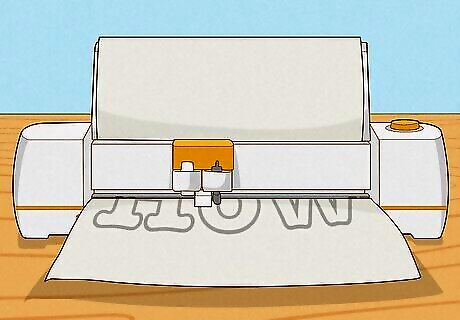

Stencil-making supplies. Traditionally, you would use screen printing emulsifier, sensitizer, and a light source to create a stencil on your screen. However, you can make homemade plastisol screen print transfers with a vinyl cutting machine (such as a Cricut) to eliminate the need for chemicals. In this guide, we'll teach you how to do this with vinyl, as it's easier for a beginner. If you want to use emulsifier and sensitizer to make your screen print stencils, follow this wikiHow to learn how.

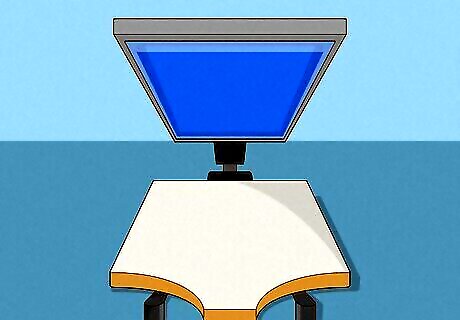

A screen printing press (optional). While you can do screen prints without a press, this tool helps smooth and streamline your process. The downside is that these presses can be expensive, with the cheapest ones sitting at around $100. This isn't required, but is recommended if you want to do screen printing often.

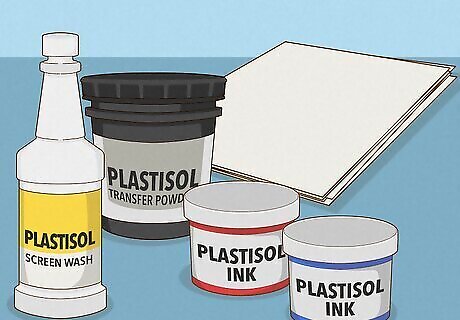

Plastisol transfer paper, adhesion powder, ink, and cleaner. To make a transfer with plastisol, you'll need some special products made for use with plastisol. Plastisol transfer paper: A special transfer paper created for use with plastisol ink. Plastisol adhesion powder: A powder that's added once you've finished your transfer to help it adhere better to the fabric you're applying the transfer to later. Plastisol ink: You need special plastisol ink to create these transfers, as regular water-based ink won't work. A popular brand is FN-INK, as it's easy to use. Plastisol cleaner: You must use a special cleaner formulated for plastisol inks, such as Ecotex Plastisol Screen Wash, to clean up your screens and any extra ink.

A flash dryer or conveyor dryer. This is necessary to cure your transfers. These pieces of equipment are expensive, but curing the ink properly with a different heating method won't be as reliable. You may also want to get a temperature gun to monitor the temperature of your ink as it cures.

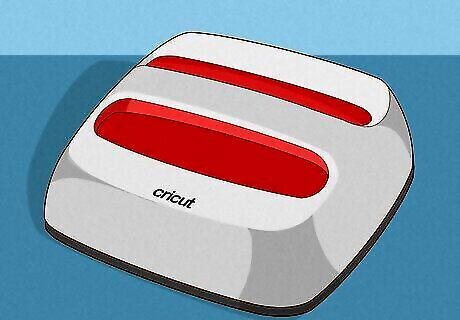

A heat press. You'll need some sort of heat press to apply the transfer. You can use a large industrial heat press or a smaller one, like the Cricut heat press.

Items to add your transfer to. A popular fabric item to screen print is t-shirts, but you can use any fabric item (like sheets, tote bags, pillowcases, tablecloths, towels, and more) to apply your finished transfers. In this guide, we'll describe how to apply the transfer to a shirt, but the process is the same for any fabric item.

Making Plastisol Transfers

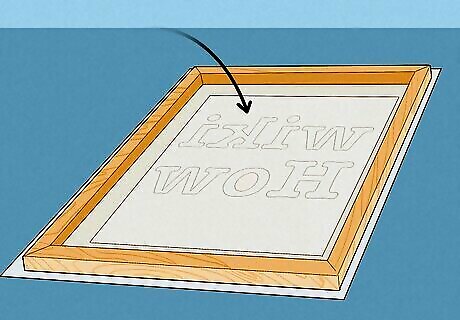

Create a stencil with your vinyl cutter. Using your vinyl cutter (such as a Cricut), cut a stencil out of vinyl with the design you want to print. Apply transfer tape to the front (non-sticky) side of the vinyl, then peel off the backing when you're ready to stick it to the screen. Unlike standard screen printing, don't cut your stencil mirrored. This will cause your final product to be backwards.

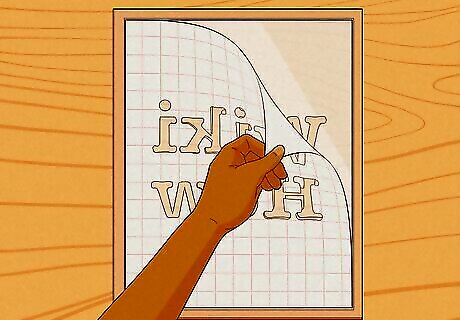

Apply the stencil to the back of your screen. Firmly press the vinyl against the back of your screen, then peel away the transfer tape. If any parts of your stencil moved during this process, adjust them before moving forward.

Place the screen over your transfer paper. Make sure the back of the screen is touching the front of the transfer paper. Your design will now appear mirrored when you look at it over the transfer paper.

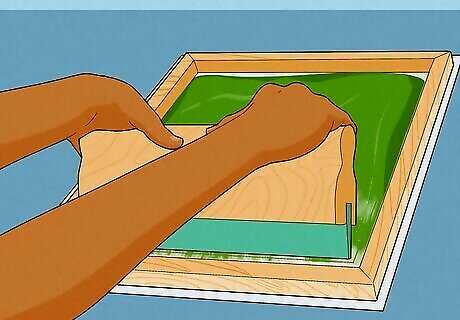

Spread the ink over your screen. Using your squeegee, spread a layer of plastisol ink over the screen. Use one firm motion to swipe down, and repeat this process once or twice more to make sure all of the ink is spread evenly over the screen and stencil. Lift the screen away from the transfer paper once the ink has been spread.

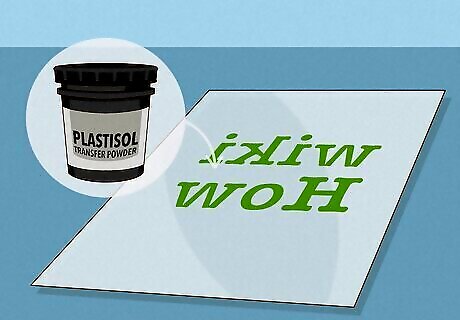

Coat the wet ink with plastisol adhesion powder. The easiest way to do this so you don't waste adhesion powder is to scoop a small amount onto the paper, then curve the paper and move the powder back and forth until all the ink is coated. Pour any unused powder back into its container, and tap on the back of the paper to loosen up any powder that's not stuck to the ink.

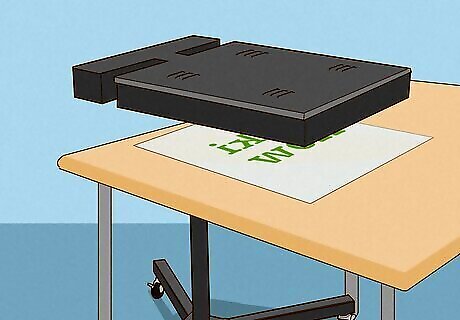

Cure the ink with your flash dryer. Place the transfer paper ink-side up under your flash dryer (or conveyor dryer, if you have one). Heat the ink to 200 °F (93 °C). This will cure it to the "gel stage," which allows you to stack the transfer sheets together without smearing the ink, but the ink won't be completely dry and cured. Use a temperature gun to monitor your ink during the curing process, and move the paper around if one spot is getting hotter than the others and curing more quickly.

Applying Screen Print Transfers

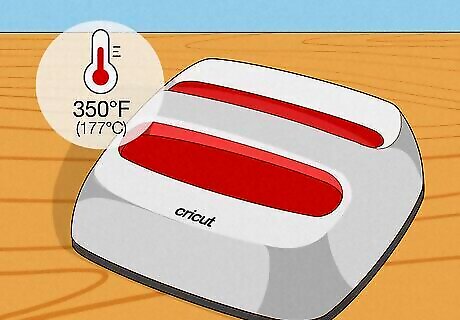

Set your heat press to 350 °F (177 °C). While the heat press is warming up, get the transfer ready on your shirt.

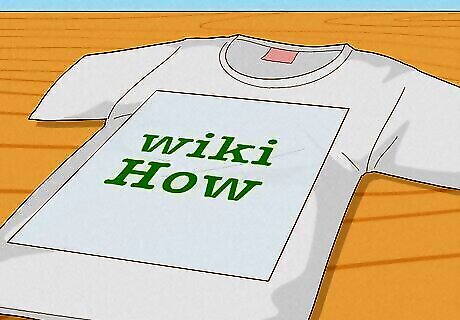

Place the transfer on your shirt, ink-side down. Ensure the design is placed where you want it and that the sheet is lying completely flat with no bumps or wrinkles.

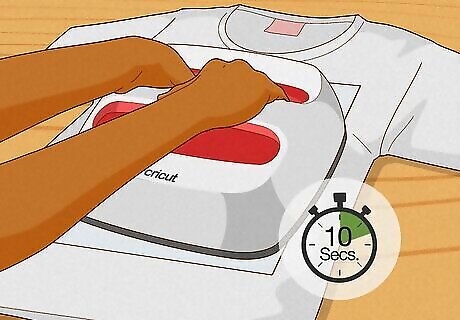

Press the design for 10 seconds. When your heat press is ready, press your design for 10 seconds. If you're using a smaller heat press than your design, you'll have to move it around until each section of the transfer paper has been pressed for 10 seconds.

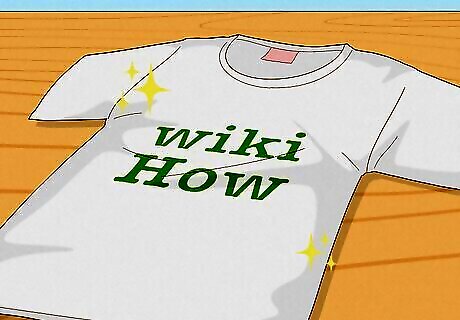

Peel the backing paper off. Pull back one corner of the transfer sheet and peel it off to reveal your finished screen print transfer.

Comments

0 comment