views

Cleaning and Handling Lead Safely

Wear a facemask, a respirator, and other safety gear. Lead welding involves a lot of the same safety concerns you encounter when working with other materials. Put on long-sleeved clothing and pants along with heat-resistant welding gloves and boots. You also need a respirator mask to protect yourself from the fumes released by the melting metal. Finish up by putting on a full face shield to cover your head. You can find welding equipment online or at some hardware stores. Also, look for industrial supply stores in your area. Since lead is so toxic, always wear gloves and a respirator when handling it. Wash your hands when you finish welding to avoid skin contamination. Keep your safety gear on the entire time you weld. You need the face mask, for example, to protect your eyes from the damaging light produced by welding torches.

Ventilate your area to remove fumes and lead dust. Lead is a very toxic metal, so don’t take any chances with it. Work under a ventilation fan capable of sucking the fumes from the melting lead out of your workspace. Use strong fans to help redirect fumes toward ventilation systems and open doors and windows. Your workspace is well-ventilated when you no longer notice dust or fumes lingering while you weld. Keep other people out of the area until you are done working and have finished airing out your workspace.

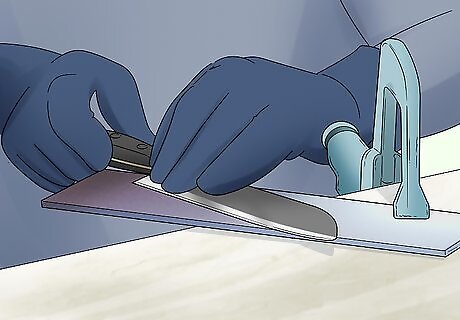

Clean the lead off with a sharp knife or steel wool. Lead is soft, so it is relatively easy to clean. If you notice white or orange oxidation spots, try scrubbing or scraping them off with steel wool. If you need to, use a lead knife to cut through the spots you need to remove. Rock the knife back and forth while pushing it down with a steady amount of pressure to cut into the lead. Remove as much debris as you can, exposing the shiny surface underneath it. You could also try soaking the lead in a weak acid like vinegar for extra cleaning power. Submerge it for up to 5 minutes. Scrub the lead afterward to remove the oxidation. Remember to wear gloves and a respirator mask! Even though you aren’t welding yet, the lead is still dangerous to handle.

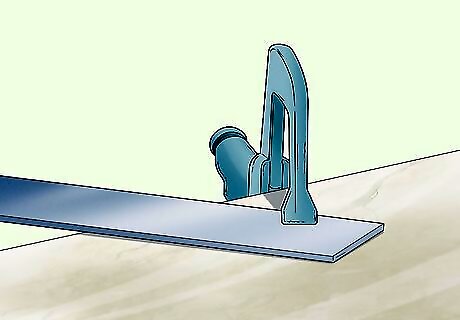

Secure the lead pieces together with clamps and tape. Set up the lead so it’s in position for you to get a clean weld. Butt, lap, and edge joints are the most common setups in lead welding. Use clamps to hold the pieces together as tightly as possible. Add foil tape as needed to keep them stable while you work. To make a butt joint, lay the pieces side by side. Weld the edges where the where the pieces touch. For a lap joint, position one piece on top of the other. The top one will partially overlap the bottom one. Then, weld the overlapping edge to the bottom piece. Make an edge joint by standing the pieces of lead up and pushing them together. Melt the top surfaces to weld them together.

Choosing and Using Welding Tools

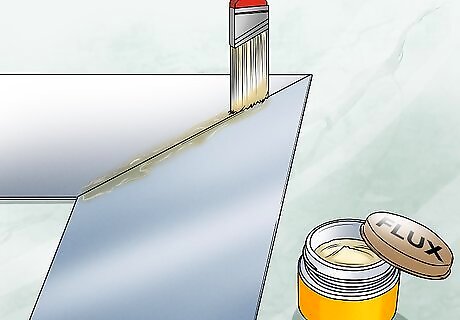

Apply a coat of flux to the welding area. Flux is a waxy acid paste that prevents oxidation, keeping the metal clean as you weld it together. When working with lead, get soldering tallow or a store-bought flux paste. Typically, you apply it with a small, dry paintbrush. Spread it liberally in a single layer over the area you wish to weld. Look for flux pastes online or at hardware stores. Try to get either tallow or a metal flux specified for use on lead. You could try welding lead without flux. Many people do it, but using the flux ensures you get the cleanest, strongest weld possible.

Select a rod made of lead to use as a filler in the joint. Find a quality welding rod that matches the lead you plan on welding. The rods you need range from 0.125 to 0.75 in (0.32 to 1.91 cm) in diameter on average. Smaller rods are better for lightweight pieces of lead while bigger ones provide extra filler for heavier pieces of lead. Pick up the lead to try to determine how heavy it feels. Try to compare it to other pieces of lead to determine what size rod to get. If you’re ever in doubt, you could simply get the bigger rod to ensure the welded joint is as strong as you can make it. The rod helps if you have a gap you need to fill in, like when you’re joining separate pieces. Expect to need a rod anytime you’re joining different pieces through a butt, lap, or edge joint.

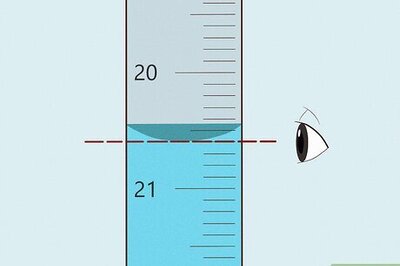

Turn on and adjust an oxyacetylene torch to the proper settings. Use a relatively small torch with a nozzle from 0.016 to 0.031 in (0.041 to 0.079 cm) in diameter. After activating the torch, turn the dials near the handle to adjust the flame. Change the settings until the flame is cone-shaped, no more than 1 to 2 in (2.5 to 5.1 cm) long. The flame also has to be all blue in order to be at the right temperature for treating lead. The dials control the amount of gas passing through the torch. Make sure the inner flame coming from the torch is soft and rounded, not pointed. Lead is soft and melts easily, so a harsh flame could oxidize or burn it.

Joining the Lead

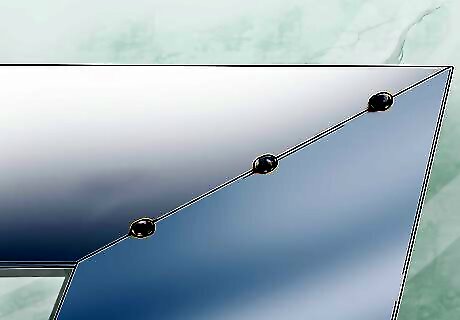

Tack the pieces together with the torch if you need to stabilize them. Tack welding is a technique you use to bind pieces together so they don’t move while you weld. To tack the metal together, point your torch straight down over the lead about 1 in (2.5 cm) above the edge of the joint. Move the torch in a small circle for about 3 seconds, lightly heating and melting the lead together. Tack the lead together at the start and end of the joint. Make these spots look like small, circular puddles right near the ends of the joint. To test the joint, pick up the lead and try to pull it apart. If you can’t pull it apart, then you secured it successfully. You don’t always need to tack weld. If you’re sure you can get a clean weld without pinning the metal together, then skip to the regular weld. However, tacking ensures the lead can’t pull apart as you work.

Hold the torch and the filler rod at opposing 45-degree angles. Stand beside the joint you wish to weld, then reach for its top end. Hold the torch behind the edge of the joint. With your other hand, hold the filler rod in front of the joint. Tilt both the rod and torch at 45-degree angles from the joint before you begin welding. This position allows you to move steadily across the joint, dripping melting metal from the filler rod into it. Make sure you feel comfortable and have the lead pieces well-stabilized before you begin. If you’re not using a filler rod, use the torch as you normally would. Brush the melted lead as needed with the tip of the torch to help fill in any gaps left in the weld.

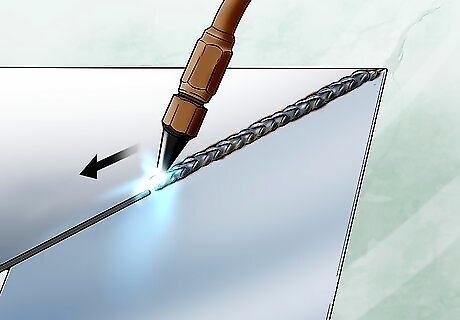

Melt the lead and solder material to begin the joint. Keep the torch and filler rod held at an angle as you begin moving it along the joint. Start at the end of the joint with the torch about 1 in (2.5 cm) above the lead with the filler rod underneath it. Heat the area until you see the lead begin to melt and a drop of the filler fall onto it. Lead melts takes only about 3 seconds to begin melting. Applying too much heat turns it into something like a very soft butter. As long as you keep the torch at an angle, the lead becomes soft and manageable without falling apart.

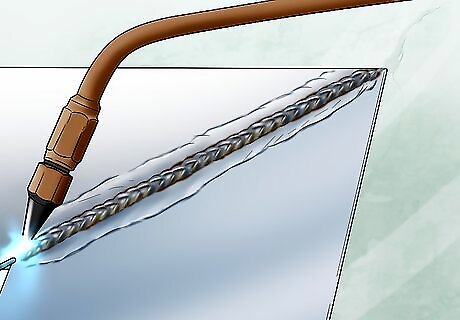

Apply solder as you move the torch and rod along the joint. Move the torch toward the rod to melt a little drop of metal off of it, then pull the torch back to smooth out the filler. Doing this creates a V-shaped weld. Continue that pattern by moving your tools forward along the joint by about ⁄2 in (1.3 cm). Repeat this process at a steady pace until you reach the end of the joint. Getting the pacing correct is a little tricky and requires practice. Move a consistent pace, spending about 1 second or less on any specific spot on the metal. This leads to a strong, consistent weld. Another option is to hold the welder so the flame is vertical over the lead, which works well for joints that are tough to reach. Melt a drop off the filler rod, then pull the welder back to let it settle. Continue doing this for 3 to 5 seconds to create a raindrop-shaped weld.

Comments

0 comment