views

Using Concrete

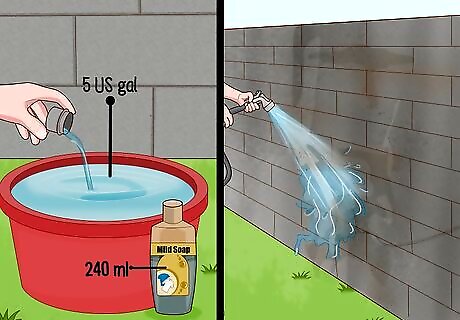

Clean debris off the wall with water and a sprayer. Remove as much debris as possible from the wall so the concrete bonds cleanly to it. Spray away most debris with water from a garden hose. Also, try mixing 1 cup (240 mL) of a mild dish soap into about 5 US gal (19,000 mL) of hot water to scrub off tough stains with a concrete brush. Use a power washer for extra cleaning power. If you don’t own one, see if your local hardware store has one to rent. For tough stains you can’t quite remove by hand, mix 1 cup (240 mL) of trisodium phosphate in about 1 US gal (3,800 mL) of water. Scrub it into the stains with a brush before rinsing it off with clean water. The chemical is strong, so cover up with long-sleeved clothing, gloves, goggles, and a respirator mask.

Mix surface bonding cement with water to a pasty consistency. The easiest product to use on a cinder block wall is surface bonding cement. All you have to do is pour the cement into a container such as a wheelbarrow, then stir in the water with a shovel. You need approximately 4 cups (950 mL) of water for an 80 lb (36 kg) bag of cement mix. Shop online or visit your nearest home improvement store for cement and all the tools you need to apply it. With surface bonding cement, you don't need to apply a concrete bonding adhesive. If you wish to use another type of cement or concrete, also get a bag of adhesive. Mix it with water and spread it on the wall first.

Wet a section of the wall again to prepare it to bond with the cement. Spray the entire wall thoroughly with water from a garden hose. Then, go back to a section of the wall to work on first. Spray it once again with water. Dampen an area approximately 3 ft × 6 ft (0.91 m × 1.83 m) in size, or as much as you can cover with cement in about 10 minutes of work. The wall needs to be well-soaked in order for the cement to bond to it. Always work on one part of the wall at a time to avoid any problems with the cement coating.

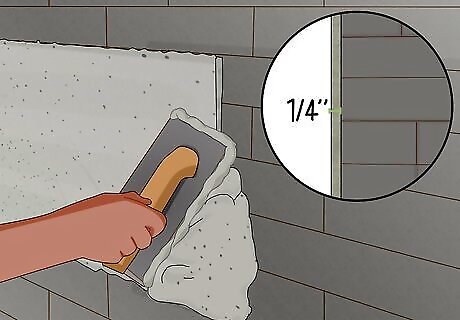

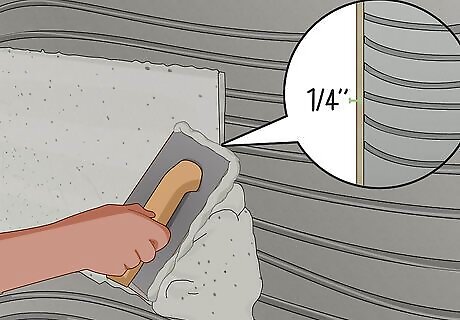

Spread a ⁄4 in (0.64 cm) layer of cement on the wall. The cement needs to be applied in sections to prevent it from drying out before you’re finished working. To prevent issues, start out by covering the small portion you dampened. Scoop some cement out of your mix with a trowel, hawk, or another tool, then slather it over the area with a trowel. Start at the top of the wall, spreading the concrete from left to right. A hawk is a flat tool used to pick up and hold lots of concrete, mortar, or other material. Normally you would have to dip into the mix many times. Using a hawk reduces this, making the application process much easier. For a faster way to cover wall sections, take advantage of a concrete sprayer. Load the concrete into the sprayer, then hold it close to close to the wall to avoid spraying the areas you aren’t ready to work on yet. If you need to check the cement’s thickness, try using a tape measure on an open part of the wall.

Repeat dampening the wall and spreading cement until you’re finished. Spray another small section of the wall, completely soaking it before applying a layer of cement. Smooth out the cement before moving onto the next portion. Keep doing this until your wall is coated in a single, perfect layer of fresh cement. If you make a mistake, scrape off the cement right away with a trowel or another tool. Cement is much easier to take care of before it hardens!

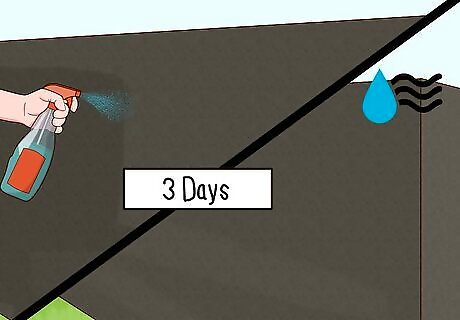

Mist and dry the cement for 3 days. Get a big misting bottle and fill it with water. Dampen the concrete twice a day for 3 days straight to ensure it cures correctly. After that, your wall is done and you can enjoy the strong but smooth finish the cement gives it. Cement can be painted over by coating it with a concrete primer. Another option is to mix colored concrete pigment into your wheelbarrow of wet cement to give it some color.

Adding Stucco

Wash the wall and remove debris to make it as flat as possible. Spray the cinder block wall with a hose to rinse off most of the debris. Look for tough stains, damaged spots, and other issues you need to address. Spend time lifting stains with soap, trisodium phosphate, and other cleaners. Also, clear debris out of damaged spots and repair them. To repair damage, mix mortar. Fill in the gaps to level out the wall as much as possible.

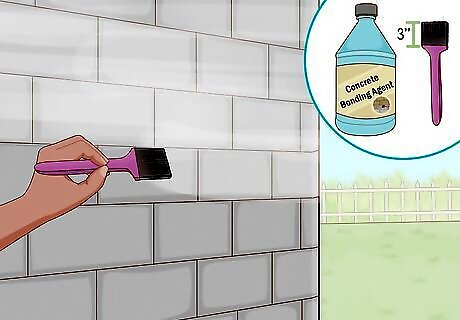

Brush a concrete bonding agent on the wall and let it dry overnight. The bonding agent provides a surface for the first layer of stucco to adhere to. If you don’t apply it, the finished wall may end up looking patchy and uneven. Use a 3 in (7.6 cm) paintbrush to go over the entire wall top to bottom. Coat the wall with a single layer of the bonding agent. Concrete bonding agents, tools, and the ingredients you need for the stucco mix are all available online and at home improvement stores.

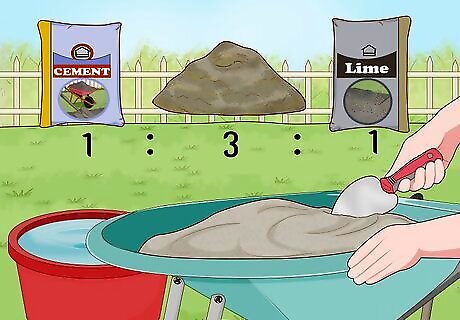

Get a stucco mix or mix your own in a wheelbarrow. Pour store-bought stucco mix into your wheelbarrow and stir in water until it has a paste-like consistency. If you’re making your own, get sand, lime, and Portland cement. Try combining 3 parts sand, 1 part lime, and 1 part cement to create a good mix that adheres well to vertical walls. You can also mix in a concrete pigment to color the stucco if you don’t plan on painting it later.

Apply a ⁄4 in (0.64 cm) scratch coat with a trowel. If you have a concrete sprayer, use it to cover large areas quickly. Otherwise, try picking up the stucco mix with a flat tool like a hawk and then transferring it to the wall with a trowel. Add the stucco to the top of the wall, then spread it from left to right, repeating this as needed to finish the layer. The scratch coat is like a second base for the outer layer of stucco, so don’t skip it. Applying a large amount of stucco all at once is a recipe for an unappealing finish.

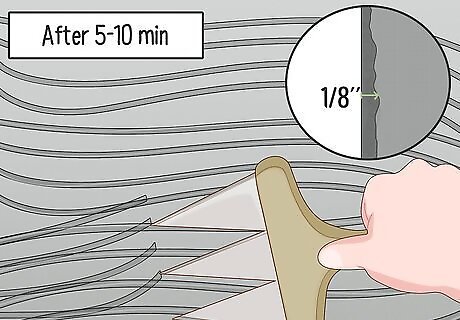

Scratch the stucco 5 to 10 minutes after applying it. Waiting allows the scratch coat to solidify it a little bit so you don’t accidentally end up scratching the wall underneath it. When you’re ready, get a tool called a scarifier, which looks like a handheld rake or comb. Rake it horizontally across the entire wall to scratch lines into the stucco. A scratch coat is a rough initial layer. You create scratch marks on it to create a base for the final layer to bond to, leading to a stronger wall covering. The scratch marks don’t have to be perfectly horizontal or even. Simply drag the tool across the wall a few times. As long as you have marks along the entire wall, you can create a much stronger finish. If you don’t have a scarifier available, use the edge of a trowel or another tool. Make the scratches about ⁄8 in (0.32 cm) deep.

Dry the stucco for 2 days, misting it twice a day. Leave the stucco exposed to harden in open air. Keep it wet by spraying it with water from a misting bottle each morning and afternoon. If you let the stucco dry out before it finishes curing, it may weaken and crack. Stucco is similar to concrete and needs to be treated the same way. Always let the first layer cure before applying a second one.

Apply a second layer of stucco and let it dry. Finish the wall cover by repeating the process with another ⁄4 in (0.64 cm) layer. This time, instead of scratching the stucco, use the trowel to create whatever finished design you want. When you’re finished, mist it and dry it for at least 2 days. For example, some designers sweep a trowel across the stucco to give it an uneven, ridged design. You could also use a scarifier to give it a scratched design or leave it flat if you wish. If you wish to use concrete pigment, don’t forget to mix it in with the fresh batch of stucco. Otherwise, you can apply wall paint to the stucco after it finishes drying.

Covering the Wall with Vinyl Siding

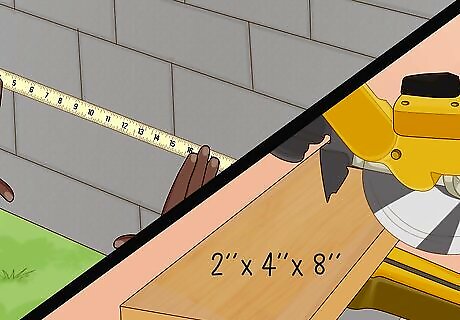

Measure the width of the wall and cut furring strips to match it. Use a measuring tape to figure out what length the strips need to be. Furring strips are little more than wood boards treated to be water-resistant. They are approximately 2 × 4 × 8 in (5.1 × 10.2 × 20.3 cm) in size. Cut 2 separate boards to the same width as the wall. Look for furring strips at your local home improvement store. Some places sell pre-cut strips, but you can also ask to have treated pine boards cut to the size you need.

Position the boards to the top and bottom edges of the wall. The first strip is easy to position since you situate it on the side of the wall at the very top. For the lower board, measure up about 6 in (15 cm) from the bottom edge of the wall. Make sure the boards go from one end of the wall to the other, adding additional boards as needed if yours are too short. Consider marking the installation points with chalk first. Check the line with a level to ensure the furring boards will form a straight row when you install them. If your wall has windows, doors, and other obstructions, keep the furring strips away from them. Install separate furring strips around each of these components, basically framing them. For soffits and fascia, you can get separate pieces of vinyl designed to fit these wood components. Slide the vinyl into a top strip or J-channel and nail them as needed to hold them in place.

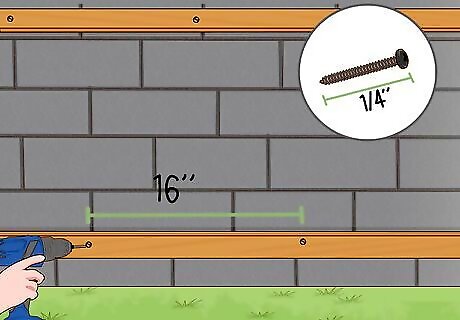

Attach the boards with screws placed every 16 in (41 cm). Measure along each of the furring strips, marking the attachment points with a pencil as needed. Use a masonry drill bit ⁄4 in (0.64 cm) in diameter to create holes all the way through the wood. Then, fit ⁄4 in (0.64 cm) concrete screws into the holes to hold the boards in place. Have a helper on hand to hold the boards in place while you attach them to the walls.

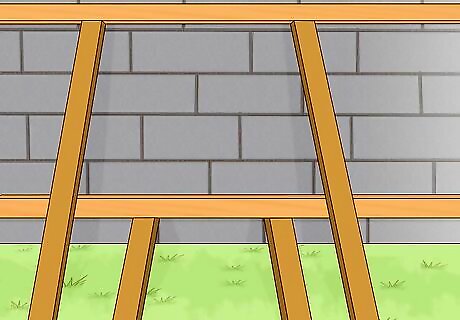

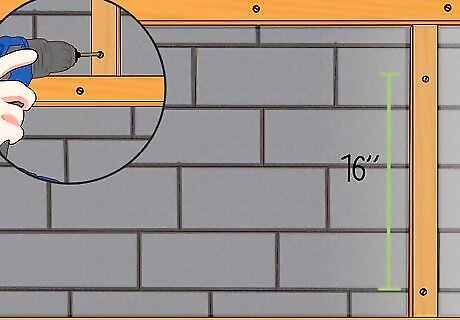

Place vertical boards along the wall to connect the strips. Cut more furring strips to the size you used previously. Line these boards up with the edges of the wall, chalking straight guidelines as needed for the installation. Drill and screw these boards to the cinder blocks. Apply more vertical strips about every 16 in (41 cm) to create a framework for the vinyl siding. Remember to install vertical boards around each door and window to complete the furring “frame.” These components need to be framed in order to waterproof them properly.

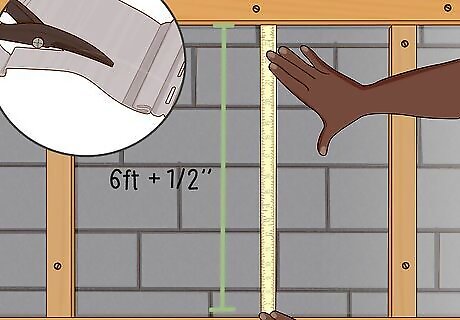

Measure and cut the vinyl to fit evenly over the wall. Run a tape measure from the top edge of the upper furring strip to the bottom of the lower one. Add an extra ⁄2 in (1.3 cm) to your measurement to account for overlap. Then, cut the vinyl panels evenly to fit over the height of the wall. Use a circular saw with a plywood-cutting blade to trim the panels. Remember to wear goggles, earmuffs, and a dust mask to keep yourself safe while operating a saw.

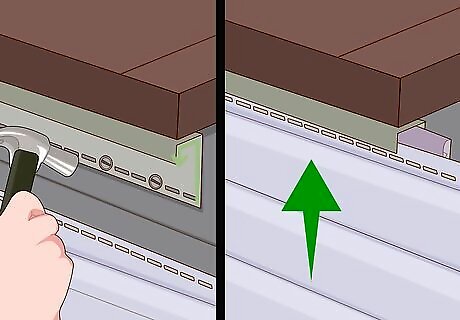

Attach a vinyl starter strip below the bottom furring. The starter strip is a slotted piece of trim used to hold the vinyl to the furring board. Position it so it extends about ⁄4 in (0.64 cm) below the lower furring. Place ⁄4 in (0.64 cm) galvanized siding nails in the slots pre-cut in the starter to pin it in place. Look for vinyl siding kits online or at your local home improvement store to get all the components you need. Alternatively, buy the parts separately to suit your wall. If you’re working around doors and windows, get more vinyl starters. You need corner pieces and J-channel pieces to connect them together. They attach to the furring boards the same way the starter does.

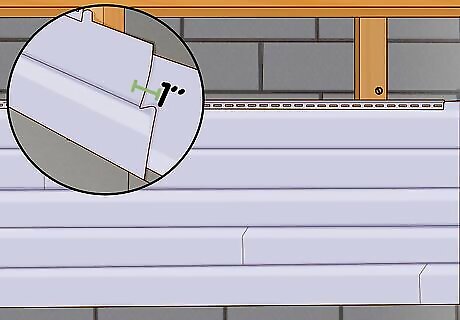

Lay vinyl panels from the bottom of the wall to the top. Position the first row of vinyl panels over the starter strip on the bottom of the wall. Work from one side of the other, pinning the panels with ⁄4 in (0.64 cm) galvanized siding nails placed in their pre-cut nailing slots. When you get to the end of the wall, start with the next row, allowing the new panels to overlap the first ones by 1 in (2.5 cm). Look for labels on the nail slots in each panel. These slots are often marked with letters to help installers line up rows of panels properly. The vinyl panels are pretty thin, so don’t put the nails in too tightly. Pound the nails in so they’re about even with the upper lip of each panel. That way, the panels can expand and contract as the weather changes.

Attach a top strip to prevent water from seeping behind the vinyl. Use a snap-lock tool to punch a hole every 16 in (41 cm) over the upper furring strip. Set a vinyl strip or J-channel over the strip. Grip the strip between tin snips to guide it onto the vinyl panels. Secure it in place with more galvanized siding nails. These are the only nails visible in the siding. Consider adding some primer and then painting over them with water-resistant latex paint.

Installing Stone Veneer

Clean the wall to remove debris and stains. Rinse the wall off with a hose, then sweep away remaining dust and debris with a concrete brush. Spray off stubborn stains with a pressure washer. Strip away any paint on the wall with a pressure washer as well. Another way to remove tough stains is by attaching a wire brush to a right-angle grinder. Use the brush to scrub off the stains.

Apply a concrete bonding agent to the cleaned wall. Dip a 3 in (7.6 cm) paintbrush into the liquid bonding agent and use it to coat the wall from top to bottom. Keep the layer as smooth as possible to ensure the veneer fits evenly on the wall. You can get bonding agents, along with any other tool you need, online or at most home improvement stores.

Combine a veneer mortar mix with water in a wheelbarrow. Prepare the mix according to the manufacturer’s instructions to get it to a firm, spreadable consistency. If you don’t wish to use a store-bought mix, try making your own instead out of masonry cement and sand. Using a pre-made mix is much simpler and faster, however. Make your own mix by combining 1 part masonry cement with 3 parts masonry sand. Put an acrylic polymer in a separate container to mix with water according to the manufacturer’s instructions. Combine all of the ingredients in your wheelbarrow to finish the mortar.

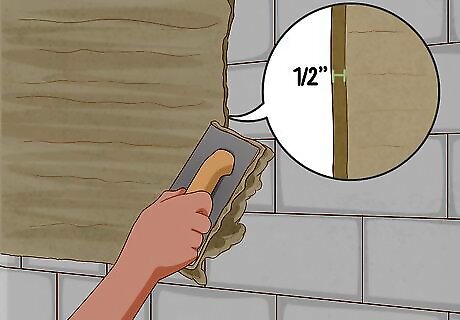

Coat the wall with a ⁄2 in (1.3 cm) layer of mortar. Try using a hawk to scoop the mortar out of the wheelbarrow and then transfer it to the wall with a trowel. Using both tools together makes the process much faster. Apply the stucco to the top of the wall and spread it from left to right with a single motion of the trowel. Continue doing this to add more mortar as needed to cover the wall and smooth out the layer until it appears uniform. Keep the layer of mortar the same depth throughout the wall so the stone veneer fits evenly on the wall. Consider scratching the mortar with a scarifier, a metal rake, or another tool to improve the finished bonding.

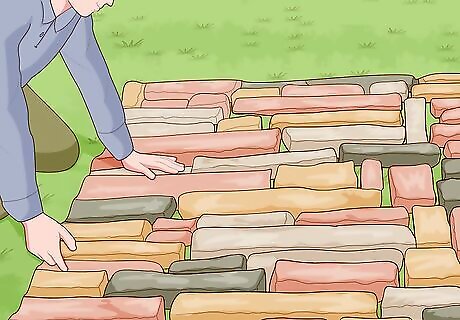

Arrange the stone panels on the ground in front of the wall. The panels fit together like puzzle pieces, but you have to assemble them first to ensure they go together. Spread them out face down on the ground and push the pieces as close together as possible to eliminate gaps. Create the finished pattern you want your wall to have. There isn’t much extra work needed to fit the panels together. The manufacturer cuts them into shapes meant to fit together. The only exception is when you need to trim the stone to fit along the edges of your wall, which you can do with a diamond blade.

Spread a ⁄2 in (1.3 cm) mortar layer on the stone veneer. When you’re ready to begin the installation, use a trowel and other tools to coat each panel. Start with the panel you intend on positioning on the lower left corner of the wall. Spread mortar around from top to bottom and left to right into a flat, smooth layer. Do this for each panel as you install it. Dampening the stones with a spray of water from a hose can help the mortar stick to them. If you need to cut the stone panels to fit on the wall, use a circular saw with a diamond-tipped masonry blade.

Install the stones from the bottom of the wall to the top. Work from the base of the wall, starting in one of the corners. Push the stone panel firmly onto the wall until mortar begins squeezing out from underneath it. Move onto the panels that fit next to and above it, leaving a ⁄2 in (1.3 cm) gap between each one. Keep this gap uniform throughout the entire wall. Try to avoid getting mortar on the stones. If you need to clean the stones, let the mortar dry, then remove it with a dry whisk brush.

Fill in the gaps with grout if you wish to insulate the wall. Mix the grout in a bucket with water according to the manufacturer’s recommendations. Then, use a trowel to pack it into a grout bag. Hold the nozzle close to the joints between the stones and squeeze the bag to apply the grout. Fill each joint until it’s about level with the stones, then carefully smooth the grout out with a trowel as needed to complete your new wall cover. Grout protects the stone veneer from moisture and anything that might grow inside the joints. Some people prefer the way the veneer looks without grout, but keep in mind that it may not last as long as a wall finished with grout.

Comments

0 comment