views

Marking the Steel

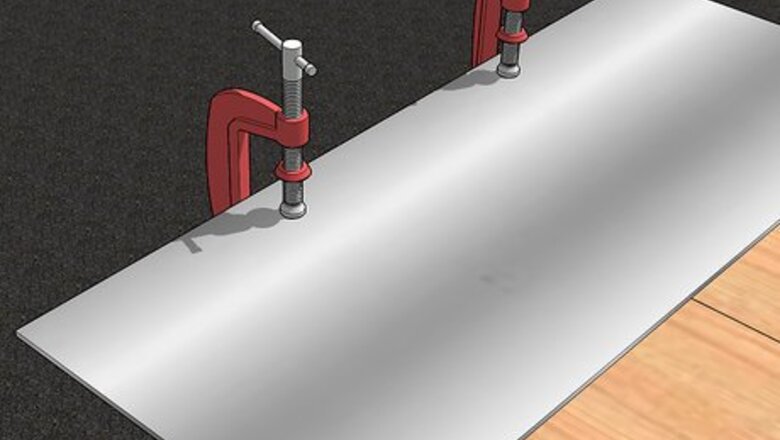

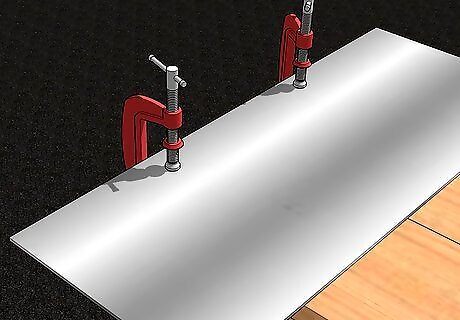

Clamp the steel to your work surface if it’s lightweight. Use plastic clamps or metal C-clamps. Tighten the clamp or vice to your workbench so the metal is secure and will not move while you try to drill. If the clamp is loose, the metal could spin while you drill it and cause you harm. If you’re working with a heavier piece of steel, you do not have to clamp it down. If you’re drilling through a painted surface, put stir sticks or shims between the clamp and your piece of steel so the clamps don’t dent or scratch the metal.

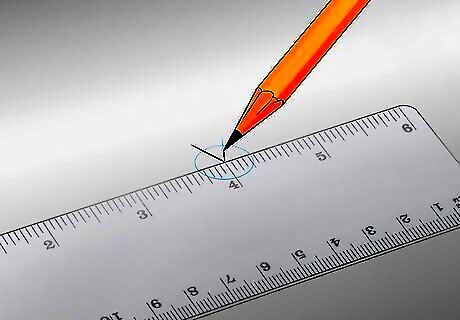

Mark the spot you want to drill with a pencil. Measure out where you want to place the hole in the steel. Take the diameter of the drill bit into consideration when you place your hole. Make a dot on the steel with a pencil to mark where the location of the hole’s center. Use a permanent marker if the pencil doesn’t show up on the steel.

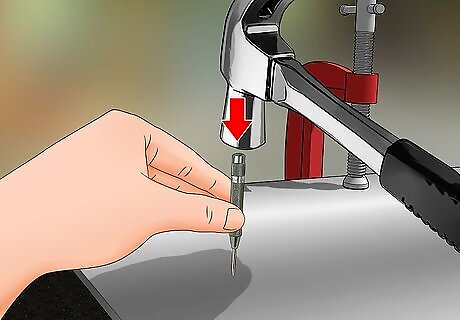

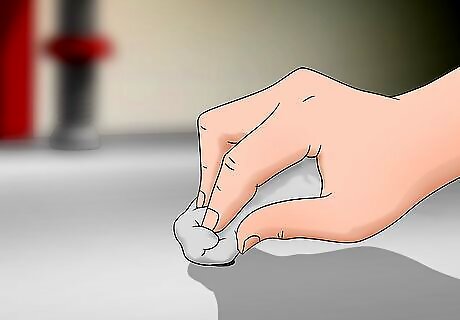

Make a divot in the steel with a hammer and center punch. Place the tip of the center punch on the mark you’ve drawn on the steel. Use a hammer to tap the punch slightly to make a small dent. This helps keep your drill in the right spot rather than it moving around while you try to make the hole. Use a nail if you don’t have a center punch.

Choosing and Lubricating the Drill Bit

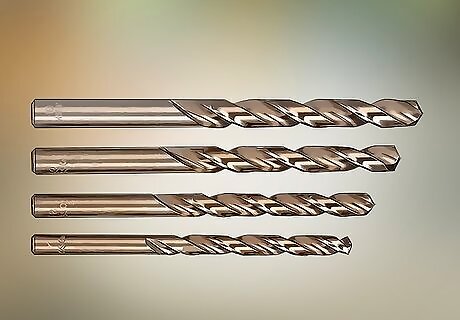

Use a sharp bit. If you're only drilling a few holes through steel, you can use a regular high-speed steel bit. If you're drilling a lot of holes, or through hardened steel, then a cobalt steel bit or black oxide bit is a better choice. Most drill bits are sold in a set with multiple sizes. If your drill bit is dull, it's not difficult to sharpen the drill bit yourself.

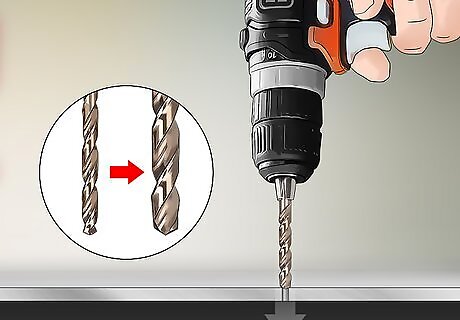

Use a drill bit half the diameter as the size you want to start. Place the drill bit in your drill and tighten it so it’s held firmly in your drill. The smaller drill bit puts less pressure on the metal and allows you to drill larger holes easier later on. For example, if you want the hole to be ⁄2 inch (1.3 cm) at the end, start by drilling a hole that’s ⁄4 inch (0.64 cm).

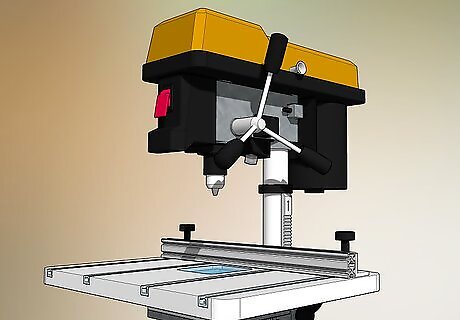

Work with a drill press for larger pieces of steel. Drill presses are heavy-duty machines that make sure your drill bit goes straight through the metal with the most accuracy. See if there is a workshop around you where you can use their drill press or purchase one for yourself. There are 2 different models of drill press that you can purchase. Choose a bench drill press for a compact option that will fit right on your workbench. Pick a floor model drill press if you plan on frequently working with larger pieces of steel. If you plan on offering metal fabrication services to others, consider getting a drill press for the most accuracy.

Use 30 weight oil and water in a spray bottle or a lubricant oil on the drill bit. WD40 is for getting water out of rusted bolts. Place the lubricant on the end of the drill bit and on the sheet of steel you plan to drill. This helps protect the drill bit and the metal to make a smooth cut. Spray the steel periodically while you’re drilling to keep it lubricated and reduce friction. Look for a 3-in-1 oil with a telescoping spout so you can lubricate the drill bit as it’s running.

Making a Pilot Hole

Wear safety glasses while working with metal. Before you start drilling, make sure you have eye protection to stop any metal shrapnel or sparks. The slivers of steel the drill can toss up are sharp and could cause damage to your eyes. Consider wearing a long-sleeved shirt and closed-toe shoes before working with metal.

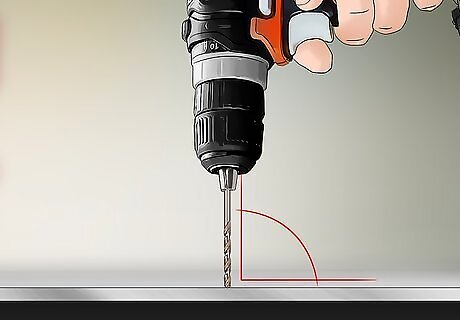

Hold the drill perpendicular to the piece of steel so the tip is in the divot. Find the divot you created on the steel and place the drill bit in it. Make sure you hold your drill straight so you don’t make a crooked hole in the steel.

Drill slowly and apply firm downward pressure. Use a low RPM setting and keep a steady pressure as you push the bit through the metal. Start and stop drilling often to give the steel a chance to cool down and lubricate the area. Drilling at a faster speed could damage the steel or the drill. Use light, but steady pressure when drilling smaller holes so you don’t break your drill bit. If you’re working with a softer steel, stay consistent at a medium speed so the metal shavings don’t melt. Keep all your clothing away from the drill bit so it doesn’t get caught. The pilot hole is usually smaller than the needed hole. Its function is to remove some of the material, making it easier for the larger drill bits to go straight later.

Pulse the drill when you’re close to breaking through the other side. Keep a firm grip on the drill, but ease off a bit of the pressure. Squeeze the trigger on the drill in short bursts until the bit goes through the other side. Keep the drill bit spinning while you pull it out from the hole. The drill may catch on the steel and try to spin in your hands. Keep your face away from the drill in case this happens.

Drilling and Cleaning the Final Hole

Drill through the metal again with the larger drill bit. Repeat the process with a drill bit for the size you want the final hole. Place the center of the bit in the existing hole and slowly drill through it again, lubricating the metal when necessary. Pulse the drill bit when you reach the end of the hole. For very large holes, gradually work up towards the diameter you want. It may take 3 or 4 different bits before you have the hole size you want. If you see smoke while you’re drilling, either slow down or use more lubricant. Some drills may have a level built into their body, but if not, use a level to make sure you’re drilling your hole straight.

Let the drill bit cool down before removing it. The steel and the drill will be hot to the touch by the time you’re finished. Give the bit at least 5 minutes to cool before changing it to a larger bit or putting it away.

Wipe away any excess lubricant and shrapnel. Use a shop cloth or a brush to wipe away any residue from drilling. Throw the shrapnel in a sharps container or separate bin. Make sure the steel is completely dry and free of debris when you’re finished cleaning it. Never wipe the metal shrapnel with your bare hands since it is sharp and could cut you.

Use a metal rasp to file and smooth the hole. Use a medium or heavy rasp on the surface of the steel to remove any sharp edges around the hole. Work lightly so you don’t damage the rest of the steel. If your rasp fits inside the hole you drilled, you can also smooth the inside of the hole for a clean and uniform look.

Comments

0 comment