views

Checking Your Appliance and Work Area

Get a gas stove that attaches to the gas source you have in your home. Your home will either use propane or natural gas, so your appliance needs to match the fuel. Before you buy your new appliance, check the gas source in your home so you can get the right type of stove. If you don’t currently have a gas line installed in your home, then you need to have one put in before you can run any gas stove. If you have one type of fuel in your home and you want to switch, then you need to have a professional install the gas lines for you. If you have the wrong type of appliance for your gas system, you may be able to have a technician convert it for you. Propane burns more efficient than natural gas and the emissions do not harm the environment.

Check that you have a 120-volt grounded outlet and range-quality gas valve. Electrical plugs for stoves have a 3-prong outlet adaptor, so the outlet you plug into must be grounded. Plug a circuit tester into the outlet where you plan on installing your stove to see if it’s grounded, and fix it yourself or hire an electrician if it’s not grounded. Then check the gas line to make sure that the gas line has a range-quality valve. If not, you may need to hire a technician to install one on the gas line for you. You can buy a circuit tester from your local hardware store.Warning: Never try to remove the grounding prong from your stove since it could cause a fire hazard when you use your stove.

Clean your work area so there’s nothing in the way of your new stove. Clear any countertops nearby and make sure there isn’t anything on the floor around the area where you’re installing the stove. Sweep the area to clean any dust or dirt from the area so it isn’t as dirty under your new stove. Double check the width and depth of the space where you’re installing the stove to make sure your appliance fits, and make any adjustments that you need to.

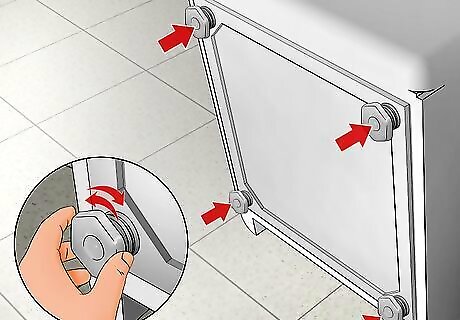

Level the feet of your new stove so they sit on the ground flat. Have a helper assist you with tipping the stove backward and laying it on a towel so you can access the feet. Rotate the feet on the bottom of the stove counterclockwise to extend them further or clockwise to retract them. Loosen or tighten each of the legs by the same amount and tip it back up to test if it’s level. If the stove wobbles, adjust any feet that are too long or short until it’s sturdy. Your floor may not be perfectly level, so your stove may wobble even if all the feet are the same length.

Attaching the Gas Line

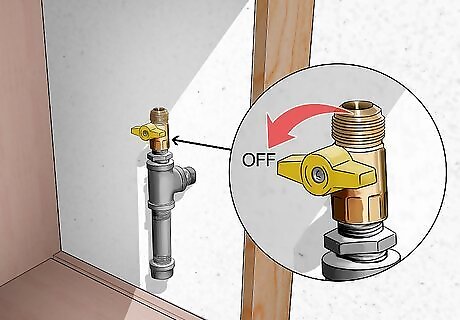

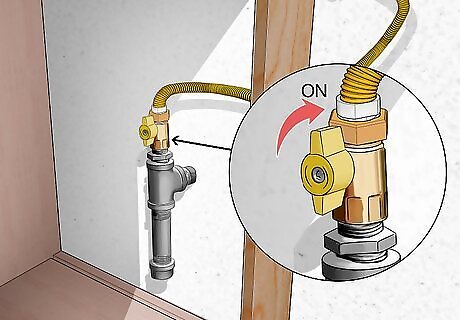

Check that the stove’s gas valve is in the off position. Locate the gas valve for your stove on a pipe near your floor behind your old stove or where you plan on installing a new one. The valve should already be off, but confirm that it’s turned perpendicular to the pipe so there isn’t a natural gas leak. Once the gas is off, you can continue working. Don’t work on your stove while the gas is still on because it’s unsafe to breathe and is extremely flammable. If you come into a strong smell of natural gas, turn off the valve and leave your home before calling emergency services. Do not use any electronics or items that create a spark.

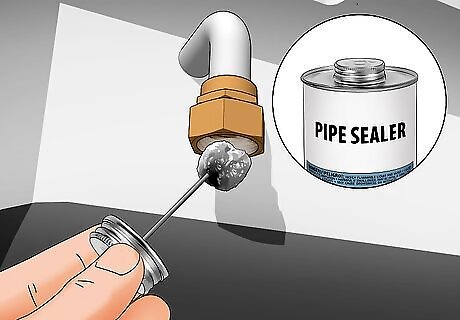

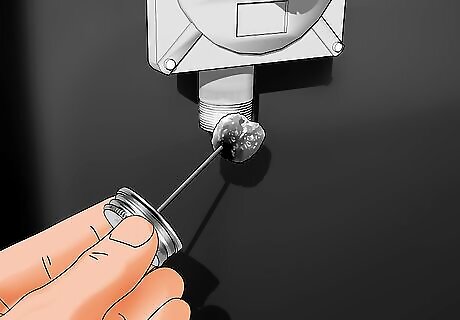

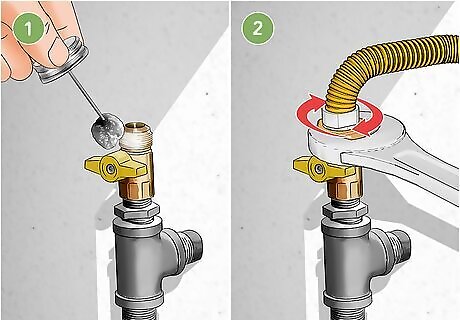

Apply pipe sealer to the threading on the stove. Get a pipe sealer that’s made to use for gas lines; otherwise, the gas will leak through the seam. Use the brush on the cap of the pipe sealer to apply a thin layer to the threaded section on your stove, which is usually located near the bottom corner. Make sure you create a complete seal around the threading so the gas can’t escape. You can buy gas pipe sealers at hardware stores. You can also use pipe sealing tape if you have it. Wrap the tape around the threading 2-3 times to form the seal.

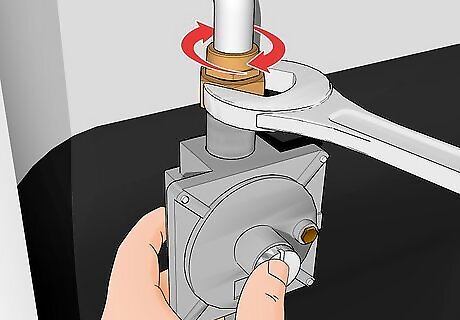

Attach a regulator to the stove if it doesn’t already have one. A regulator is a box-shaped piece of pipe that controls the pressure of the gas entering your stove. While most stoves come with a regulator built in, you may have to attach one to some models. Buy a regulator that matches the brand and output of your stove and screw it onto the pipe threading you applied the sealer to. Spin the nut on the regulator clockwise until it’s hand-tight, and then use a wrench to tighten it as far as you can. You can buy stove regulators at appliance stores or online.Tip: If it’s difficult to attach the regulator directly to your stove, you can connect an elbow pipe first so you have more space for the regulator. Just be sure to seal the elbow pipe before attaching the regulator so it doesn’t leak.

Seal the threading on the regulator with the pipe sealer. Dip the brush back into the gas pipe sealer and rub it around the threading on the end of the regulator. Make sure you make a complete seal or else the gas could leak out from your pipes. Work within 5 minutes after you apply the sealer so it doesn’t dry before you attach it. Only use a sealer meant for gas pipes to prevent leaks.

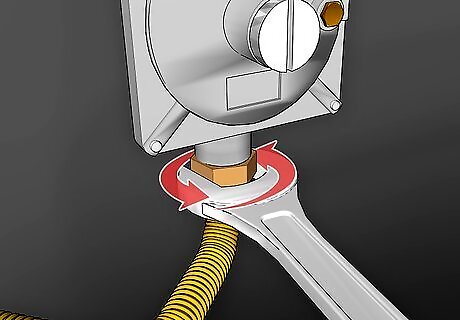

Screw a flexible gas line onto the stove with a wrench. A flexible gas line is made of corrugated metal and can easily bend to fit into tight spaces. Make sure the flexible gas line has the same size threading on the end or else it will not fit your stove without an adaptor. Screw one end of the gas line onto the regulator’s threading by hand. When you can’t turn it anymore, hold the nut on the regulator in place with channel lock pliers and tighten the end of the gas line using a wrench. You can buy flexible gas lines from hardware or appliance stores. Don’t reuse an old flexible gas line since it may be more prone to leaking.

Put sealer on the threads of the main gas pipe before attaching the flexible line. Coat the threaded port on the main gas pipe with your pipe sealer so the gas doesn’t escape. Screw the flexible gas line clockwise by hand until you can’t turn it anymore. Grip the nut on the main gas pipe with channel lock pliers so it doesn’t move around, and use an adjustable wrench to tighten the flexible pipe more. Be careful not to overtighten the pipes since they could crack or get damaged.

Testing Your Gas

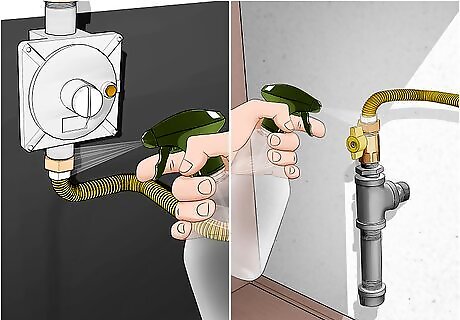

Combine dish soap and water in a spray bottle. Fill a small spray bottle with water from your sink and add a few drops of liquid dish soap. Shake the bottle so the soap mixes with the water and forms suds. Test spraying the bottle in your sink a few times to make sure it works before using it to check your pipes. You can also use a gas leak detection liquid if you want. You can buy the detection liquid from your local hardware store.

Turn the gas back on for your stove. Find the valve on the main gas pipe for your stove, which should be perpendicular to the pipes and in the off position. Rotate the valve so it’s parallel to the pipes so the gas is on. This allows the gas into the flexible line and stove so you can check the seals between the pipes. If you can smell natural gas after you turn on the gas, then immediately turn it off and reseal the gas lines.

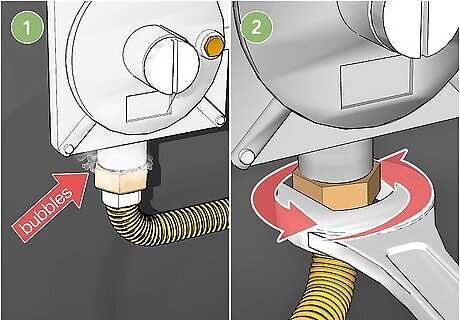

Spray the soapy water onto the gas line connections to your stove. Hold the spray bottle as close to the connections you sealed and spray some of the soapy water onto them. Make sure you apply the soapy water all the way around the pipe so it’s completely wet. If there’s a gas leak, the soapy water will start to bubble around the connections so you know that there’s a small leak. Check each of the connections you made and mark any of them that are leaking. If the soapy water doesn’t bubble, then you don’t need to make any changes.

Tighten any loose connections before testing for leaks again. Hold the nut on the main gas pipe in place with your channel lock pliers and then use a wrench to tighten the flexible line. Screw it on until you can’t get it any tighter. Repeat the process for any other connections that were bubbling after you applied the soapy water. When you’re finished, spray more soapy water onto the connection to check it again.Tip: If the pipes are still leaking after you tighten them, then you may need to reapply the sealer to the threadings.

Push the stove into place so it fits in the space. Carefully slide the stove into the space where you plan on installing it. Continue pushing it back until the front of the stove is in line or slightly extends out from the front of your counter and cabinets. Use a level on top of the stove to ensure that it still sits flat, and adjust any feet as you need to. Ask a helper to assist you so you don’t damage your floors by accident.

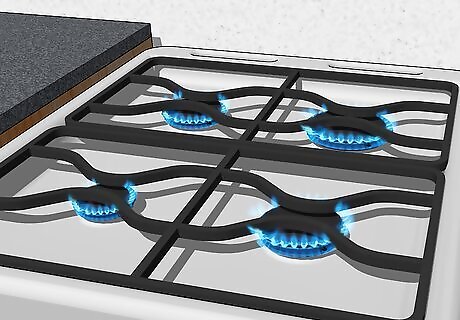

Turn on each burner individually to test them. One by one, turn each burner on your stove onto high until you hear the igniter clicking. The igniter will take about 4 seconds before the flame starts, but it may take slightly longer the first time you turn it on. Once the flame starts, turn the burner to low to ensure the gas flow adjusts properly. Turn the burner off when you’re done testing it before moving onto the next one. If the burners do not work, then you may need to check your gas supply line again to see if the valve is turned on. If it is, then you may need to contact a technician to check your stove for you.

Comments

0 comment