views

Choosing Parts for a Pickup

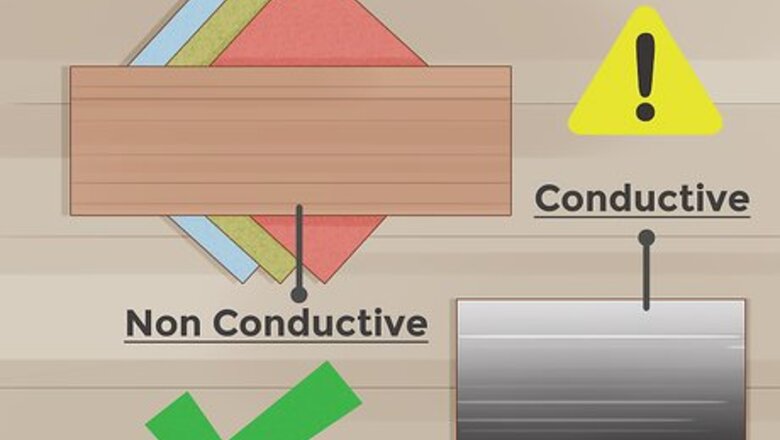

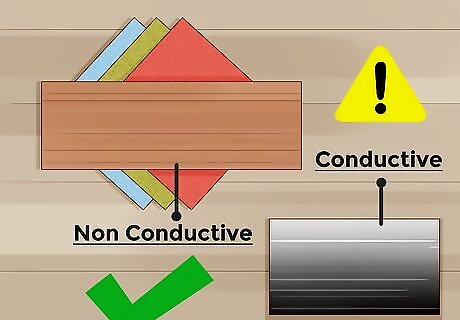

Choose a nonconductive casing material to form the pickup’s frame. Some common frame materials are wood and fiber sheets. These materials are great for pickups that produce loud, clear sounds. The parts are easy to make from scrap pieces, but you can also buy premade ones online. If you make your own, you will need to cut them to size and drill holes for the magnets and screws. If you make the frame out of a conductive material like metal, for instance, the pickup will sound differently. Sound passes more slowly through metal than wood or plastic. Most pickups are made with nonconductive casings to create a clearer sound quality. You will need at least 2 pieces of material to create a top and bottom flatwork piece. A basic pickup frame is about 3 ⁄2 in (8.9 cm) long and 1 ⁄2 in (3.8 cm) wide, although this varies between guitars. You can make a pickup out of almost anything, including rulers and CD cases. The material you choose affects the sound quality slightly. Avoid using metals and magnets for the frame.

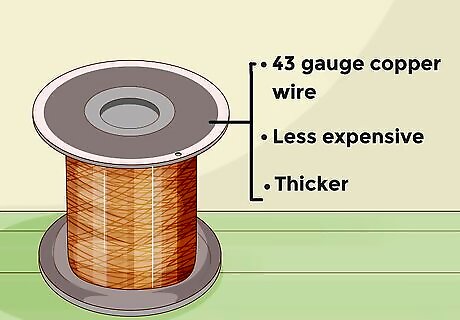

Pick copper wire for an inexpensive way to produce sound. Wrapping the wire around the pickup is often the most time-consuming step. Copper or enamel wires are thicker than silver wires, which means less wrapping. Copper wire is also less expensive than silver. Get a spool of 42 or 43-gauge copper wire. You will need about 4 ⁄2 in (11 cm) to cover the entire pickup.

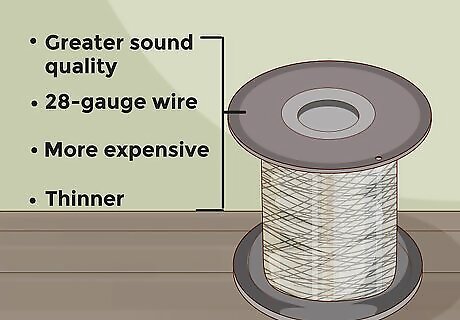

Use silver wire to create clearer sounds. Silver wire is more expensive and it’s thinner than copper wires. The advantage of silver is that it produces greater sound quality. This isn’t good for all styles of music, such as rock and metal, but it works well if you like standout guitar melodies. Look for 28-gauge silver wire. If you find a thicker wire, use that for the pickup to save time and money.

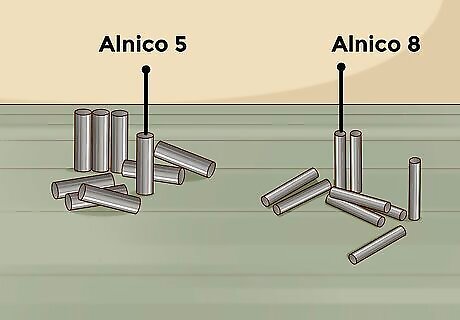

Select rod magnets for brighter guitar sounds. The most popular magnets are Alnico 5 magnets. Stronger magnets such as Alnico 8 are available, but they cost more. You will need 2 magnets for each string your guitar has. Stronger magnets give off a louder, more aggressive sound and output more volume. Magnets are available online, but you may be able to find them at some guitar supply shops. Hardware stores often have usable magnets other than Alnico magnets. Ceramic magnets are similar to basic metal magnets but produce a stronger mid-range sound and louder bass, making them a good choice for fast metal songs. Flat magnets are also available. They work the same as rod magnets but are a little trickier to install.

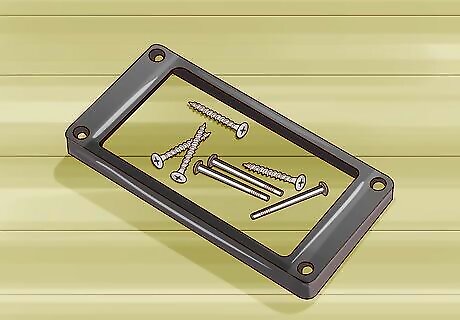

Make the pickup with metal screws for a clearer sound. Metal components ring. They give your music a sweeter, more simplistic sound closer to old-school rock from the 60s. They don’t do as well as magnets for more aggressive music, but metal components are often cheaper and easy to work with. If you choose to use metal screws, you will need some round neodymium magnets to place on top of the screws. For metal components, get some scrap machine screws or pole-piece screws. You will need 1 for every string your guitar has.

Creating the Pickup’s Base

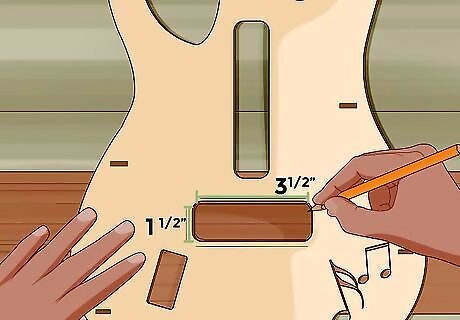

Sketch the pickup’s outline on a piece of nonconductive material. Wood and fiber sheets are most often used in pickups. If you’re building a pickup for a specific guitar, get the guitar’s faceplate and place it on top of the wood. Outline the shape of the pickup in pencil. A basic pickup is about 3 ⁄2 in (8.9 cm) long and 1 ⁄2 in (3.8 cm) wide, although this size varies between instruments. Many guitarists prefer maple for the sound quality it produces, but other types of surfaces work well. For example, make the flatwork out of old rulers or buy some vulcanized fiber sheets. Another way to make the outline is to cut a template out of a separate material like paper or acrylic. Then, use the template as a guide to hone the wood to the proper size.

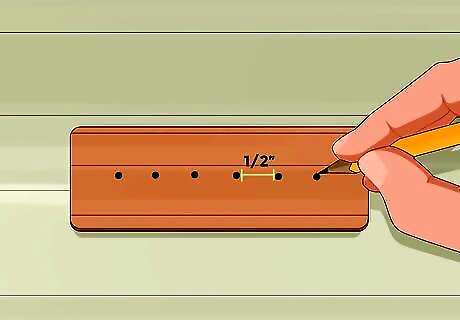

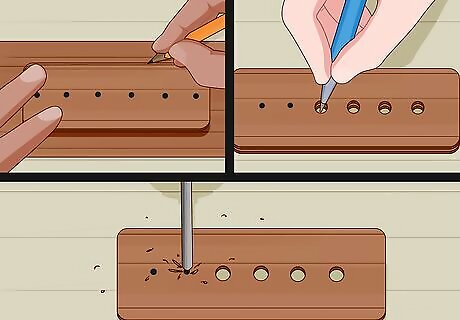

Measure and mark where the screw holes will pass through the frame. The number of holes you need to make depends on how many strings your guitar has. A standard pickup is bar-shaped and has 6 holes centered along its length. Leave about ⁄2 in (1.3 cm) of space between each hole. The screws that will go into each hole must not touch when they’re installed. If you already have some machine screws, pole-piece screws, or magnets, measure their diameter. Use the diameter measurement to place the screws an equal distance apart. Leave at least ⁄2 in (1.3 cm) between the screw heads and the edges of the wood flatwork.

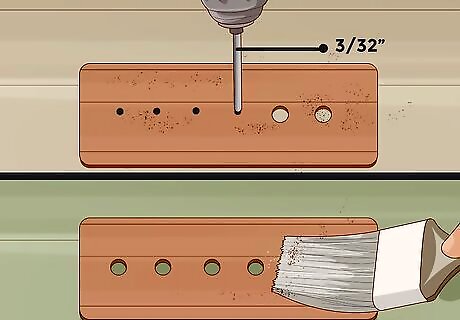

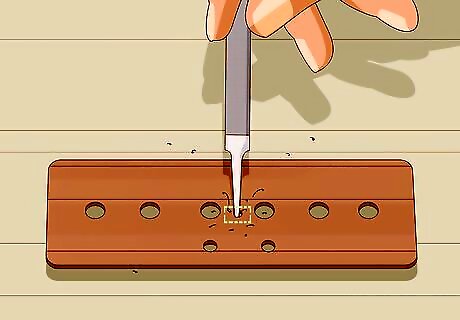

Drill holes in the flatwork with an electric screwdriver. Plan on using a drill bit that is ⁄64 in (0.040 cm) smaller in diameter than the screws or magnets you will use for your pickup. A drill bit about ⁄32 in (0.24 cm) in size works well for an average pickup. Drill all the way through the flatwork. Brush away any dust and debris when you’re done. If you have a template, use it for guidance. Drill through it first, then set it on top of the flatwork. Drill down into the holes again and through the wood to get perfectly aligned holes.

Make a second flatwork out of the same material. Go through the steps again to create the bottom part of the pickup. Make the piece the same size as the original flatwork, then drill another series of holes in it. Make sure both flatwork pieces and their drilled holes align perfectly. To easily make this piece, use the first flatwork as a template. Sketch an outline, then drill through the original holes to create same-sized holes in the new piece.

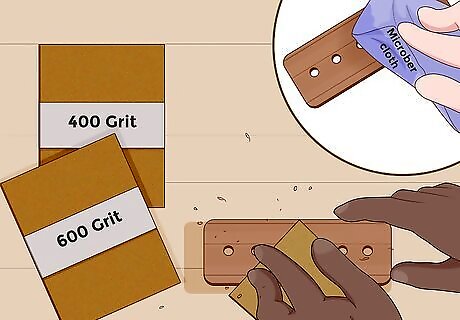

Sand and file rough edges off of the flatwork pieces. If you made the pieces out of wood, get a piece of super fine sandpaper rated between 400 and 600 grit. Applying light pressure, rub the flatwork until it’s smooth. Remove any wood shavings stuck in the screw holes. When you’re done sanding, lightly dampen a microfiber cloth and wipe away the sawdust.

Fitting a Pickup with Screws

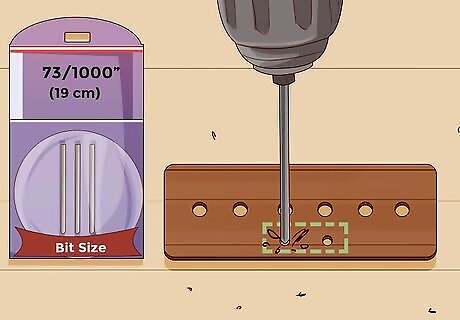

Drill a pair of eyelet holes through the lower flatwork. Find some space in the corners on 1 side of the piece. Use a drill bit about ⁄1000 in (0.19 cm) in diameter. Make a single hole in each corner. If you don’t have spaces in the corners, look in the middle part of the flatwork. Many manufacturers leave space along the edges for the eyelets. Place the eyelets close together on the same side of the flatwork.

Drill a small hole in the lower flatwork with a wood file. Find room for the hole wherever you have space in the flatwork’s center or near an empty corner. Use any small drill bit you have available. The hole will be an anchor point for the copper wire you need to wind later, so make it as small as you can. For an easier time wiring the pickup later, make an additional slot. Hold the flatwork vertically, then use a file to carefully cut down towards the hole. Keep the file slot narrow so the wire can’t slip out through it.

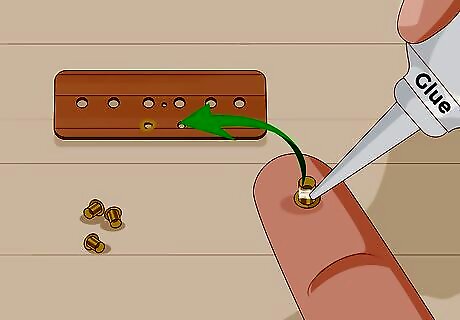

Glue brass eyelets into the eyelet holes. The eyelets are like little screws, except they open at both ends. Position the eyelets so the larger, rimmed ends are faceup. Then, spread some wood-safe super glue around the edges of each eyelet, filling in the gaps between the metal and the wood. If you used a different material like plastic for the frame, make sure the glue adheres well to it. If you don’t have super glue, you can use epoxy or a polyurethane-based glue. Epoxy is the stronger adhesive, but you need to mix resin and hardener in a separate container, then quickly brush it onto the eyelets. Super glue and epoxy are good for just about any type of pickup frame, including those made out of plastic.

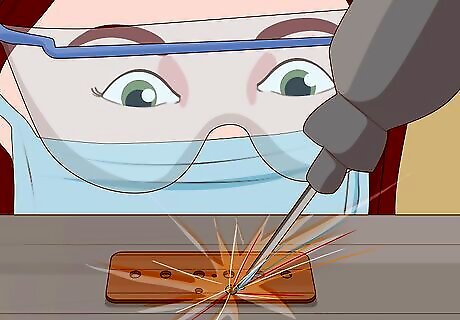

Use a rotary grinder to level the eyelets. Put on a good pair of polycarbonate goggles and ear protection. Then, flip the flatwork over and fire up the grinder. Wear down each eyelet until it’s flush with the flatwork. Some grinders are attachments that fit on power drills so you don’t need to buy a separate tool.

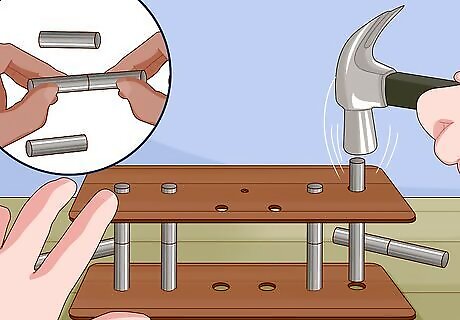

Install rod magnets if you need your guitar to sound brighter. If you have a 6-string guitar, get 12 small rod magnets and set them on a table. Connect the magnets to form 6 pairs. Push the magnet columns through the holes in the flatwork pieces. Hammer them down gently until they’re level with both flatwork pieces. The number of magnets you need will vary depending on how many strings your guitar has. Remember that magnets have both a north and south polarity. Opposite polarities attract. Use a compass to identify the polarities. Make sure the magnets are aligned the same way. For instance, position them all so the north polarity is faceup, fitting into the upper flatwork.

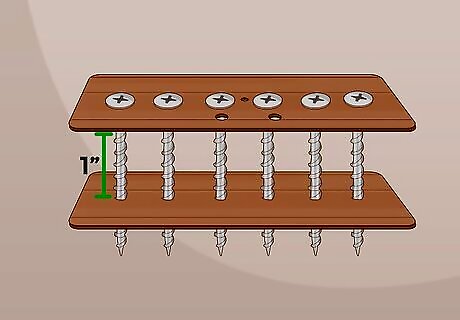

Fit machine screws into the holes if you aren’t using rod magnets. You will need 6 screws for a regular 6-string guitar. Position the top flatwork over the bottom one. Thread the screws through the top flatwork, then slide the bottom one up onto the shafts. Make sure the screws are as straight as possible between the flatwork pieces. Position the flatwork pieces about 1 in (2.5 cm) apart. The exact spacing depends on the size of your guitar. You may need to adjust the positioning to get the pickup to fit. If the screws aren’t straight, they will affect your guitar’s sound. It will sound okay if they’re not perfect, but if they look really off, consider remaking the flatwork pieces.

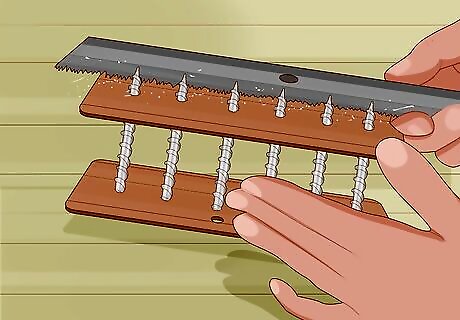

Saw the screws off with a hacksaw. Clamp the flatwork to a workbench with the bottom screws faceup. Put on protective goggles to prevent metal fragments from getting into your eyes. Then, saw all the way through the metal screws so they’re flush with the bottom flatwork.

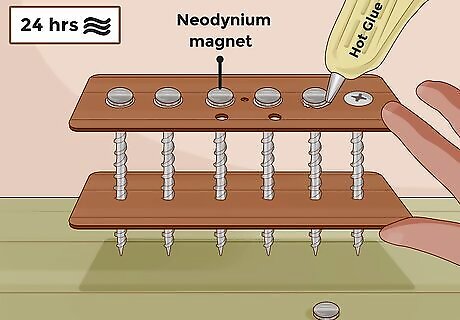

Fit circular magnets on top of the screws. Get a neodymium magnet for each screw. Set it over the screw head above the upper flatwork. It will stick in place. To seal it, spread some |hot glue, super glue, or epoxy around the magnets and screw heads to hold them in place. Give the glue about 24 hours to cure properly. If you’re using rod magnets, you don’t need the neodymium magnets at all. Simply spread some glue around the base of each magnet to secure it to the flatwork pieces.

Wiring the Pickup

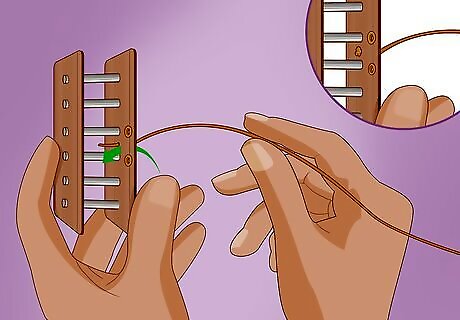

Knot a 42 gauge copper wire in the small wire hole. Buy a spool with at least 4 ⁄2 in (11 cm). You need a lot of wire, so don’t worry about getting too much. Unspool some of the wire, then slide it into the small hole with the groove you made. Knot the wire in place, but don’t cut it from the spool yet. If you don’t want to buy new wire, repurpose wire from scrap electrical components like wall plugs and old pickups. Heat the wire lightly with a pocket lighter to loosen the adhesive holding it in place. Using silver wire is also an option. Remember that it is thinner, more expensive, and produces a clearer sound, so it isn’t always the best choice.

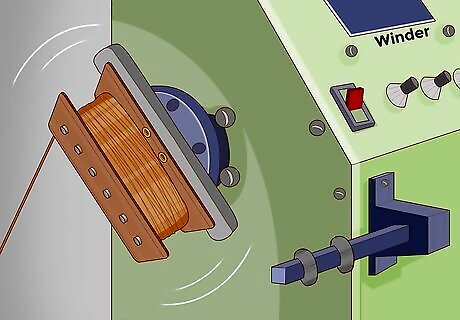

Wind the wire around the pickup’s screws or magnets. The easiest way to do this is with a pickup winder. Fit the pickup on the winder and wrap the wire once around its center. Then, run the machine, loading as much of the wire as you can fit. When done correctly, the pickup will have a thick, even wrap of wire around it. Pickup winders are available online. Some music supply stores also stock them. Many pickups are wrapped between 8,000 and 10,000 times. You don’t need to count how many times the wire goes around the pickup, though. As long as the layer of wrap looks thick and even, the pickup will work. Another way to do this is with a drill or a fishing reel. Drill a small hole into the center of the bottom flatwork, then let the pickup spin.

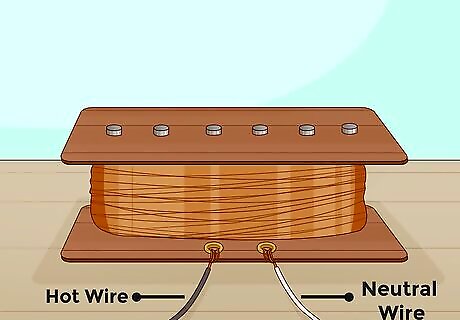

Get 2-color electrical wires for your pickup. A standard single-coil pickup has 2 wires. The wires will be colored black and white. The black wire is the hot wire and the white wire is the neutral wire. You will need to connect the wires to the brass eyelets to power the pickup. Some guitars have a red wire or green wire. Red wires are hot wires and green wires are ground wires. For a double-pickup humbucker, you will need a 4-color electrical wire. The 2-color wire isn't enough to power both pickups.

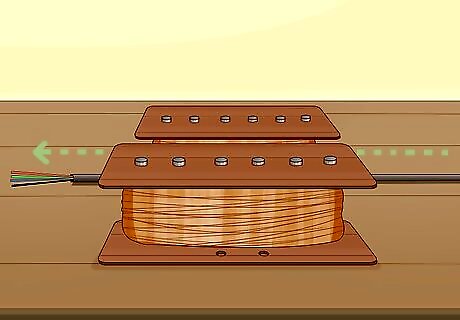

Pass a 4-wire cable between pickups if you’re making a humbucker. A humbucker is a guitar with 2 magnetic coils. Set the pickups side by side, then thread the wire between them. Make sure the wires stick out from between the pickups so you can connect them to the eyelets. The wire will have some color combination like red, blue, black, and green. To make a humbucker, you need to build a second pickup. Make it as identical to the first pickup as possible. A good humbucker eliminates electrical interference and produces a more well-rounded sound.

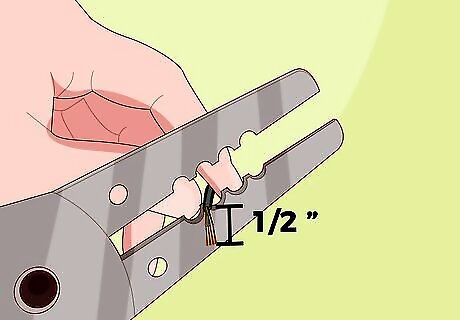

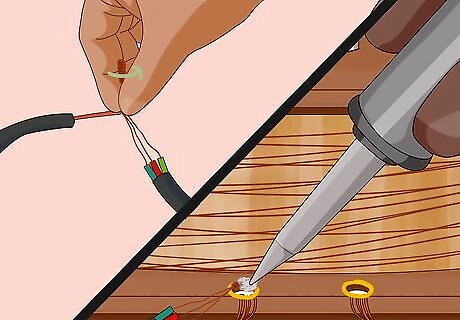

Use wire strippers to expose the ends of the wires. Hold the wires in place, then grip the ends with a wire stripping tool. Clamp down until the tool breaks through the colored insulation. Pull the tool forward to tear off the casing, exposing the copper wire underneath it. Expose about ⁄2 in (1.3 cm) of each wire. Make sure you have enough of the exposed wire to work with. You may need to cut and strip the guitar’s wires as well if they look frayed.

Solder the wires to the brass eyelets or to like wires. Find the wire coming from the guitar, which will likely be a black wire. Twist the wires together, then melt them together. Position the remaining wires over the brass eyelets and solder them in place. For a humbucker with 4 wires, solder the red wire to 1 eyelet, then solder the green and blue wires to the other eyelet.

Comments

0 comment