views

X

Expert Source

Alberto DeJesusConstruction Specialist

Expert Interview. 15 December 2021.

Choosing and Applying the Right Attachment for the Job

Pick a wire brush attachment for cleaning and paint removal jobs. Clamp down the item you're working on so it doesn't move around. When applying the wire brush to the edge of something, position the angle grinder so the brush spins away from the object you're grinding rather than into it. Try buzzing off dirt that's set on garden tools. It will even work on set-on cement. Pick the cup wire attachment for flat surfaces and the wheel to get into crevices.

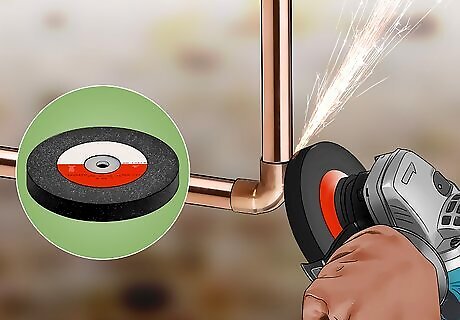

Opt for a cutting wheel for slicing through metal, tile, or concrete. A cutting wheel works much like a saw. You press it lightly on the object you want to slice through, and it will make short work of things like metal rebar and tile. Make sure to pick the right type of blade for the project you're working on. For metal, a cutoff wheel works well, and it's fairly cheap. For masonry, tile, and concrete, choose a diamond wheel. Read the attachment to know what materials you can use the wheel on.

Try a diamond tuckpointing wheel to remove mortar. If you have loose mortar in your brickwork that you need to replace, use this wheel to do the job. Run the wheel between the bricks, making several passes to get it all out. Try not to get closer to the brick with the tool than ⁄8 inch (3.2 mm). Pick a tuckpointing wheel that's about the width of your mortar to make the job go faster.

Refine edges on metal tools with a grinding wheel. Metal tools get dull from time to time, including things like ice scrapers, lawn mower blades, hoes, and hatchets. Press a grinding wheel up against the edge with the grinder off, positioning it perpendicular to the blade. Adjust the grinding wheel so that it's at the same angle as the edge of the blade and the wheel will turn away from the edge rather than towards it. Lift the wheel off for a moment. Turn the grinder on and make several light passes along the blade, following the correct angle. Don't let the blade get too hot, as it will become very brittle. If it turns black or blue, give it a rest for a moment. Check the wheel for the arrow showing you which direction it will rotate when on.

Operating an Angle Grinder Safely

Put on safety gear like goggles, long sleeves, and full-face protection. One of the main dangers of an angle grinder is flying debris, including pieces breaking off of the tool's attachments. Protect yourself with safety gear so you don't catch a piece in your eye. Safety goggles are good, but a full face shield is better. Also, protect your arms and hands with work gloves and long sleeves. Put in ear plugs or cover your ears with noise-canceling earmuffs, as the sound from the machine can get very loud. Wear a dust mask for particularly dusty jobs, like sanding and grinding mortar.

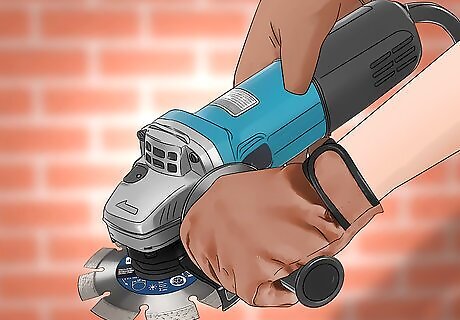

Support the tool with both hands. Grasp the handle with 1 hand. If your tool has a dead-man switch, hold onto that with this hand. A deadman's switch is one you must continually hold in place while the tool is on for it to work. Use your other hand to hold the weight of the tool. Grab the handle with whatever hand feels most comfortable. The deadman's switch is a safety feature. If you accidentally drop the grinder, it will go off automatically.

Let the grinder come to full speed before applying it to the surface. Hit the power button to turn it on. Whether you're cutting, grinding, or sanding, allow it to come up to speed to help you keep your actions smooth and consistent. For instance, if you're cutting through metal or other materials, you'll get a better cut if the cutting disc is at full speed first.

Move the angle grinder around constantly when sanding or cleaning. Don't keep the tool in one place when sanding, as you could end up with gouges. For a smoother finish, move in a rotating motion over the surface. If you're trying to smooth or clean one particular area, don't hold it in place; just move it around and over the area until it's to your satisfaction.

Apply the tool with light pressure when cutting or grinding. Let the tool do the work for you. In fact, just hold the grinder on the object, and the rotation will cut or grind for you. If you press down too hard, you could cause the tool to yank on the piece you're working on, which in turn could make the tool kick. When a tool kicks, it could lead to injuries. With sanding, you can apply a bit more pressure.

Use the correct angle for the wheel attachment. For sanding, apply the tool at a 5°-10° angle to the work surface. For grinding, try a 15°-30° angle; make sure you're using the flat part of the wheel when using this attachment. With cutting, use the side of the wheel to cut the piece head-on, meaning you should hold the wheel perpendicular to the piece you're cutting.

Keep the guard on no matter what you do. The guard may get in the way on some projects, but don't take it off. It provides some protection from flying debris if the wheel or attachment shatters. It's much better for the guard to take the hit then your torso or arms!

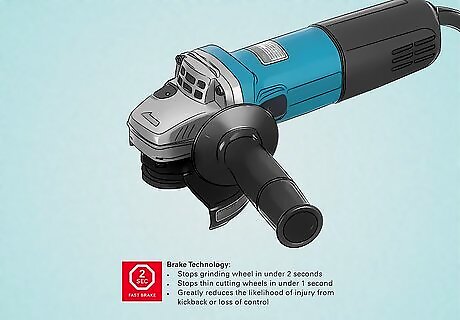

Check the grinder has stopped spinning completely before putting it down. If the wheel is still spinning at all, it can move around on the surface you set it on. Apply the braking system if yours has one to make sure it's stopped. Otherwise, just wait for it to come to a full stop. It might start cutting things you don't want to cut or even flip back towards you.

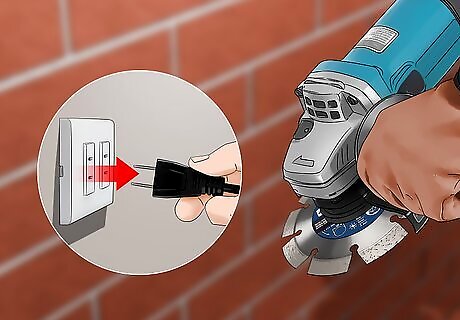

Unplug the tool when you're not using it. You don't want the tool to come on accidentally, and turning it off is not enough. Unplug it from the wall so there's no chance it could come on and harm you or someone else. Set the grinder wheel-side up on a table when you're not using it.

Picking Angle Grinders and Accessories

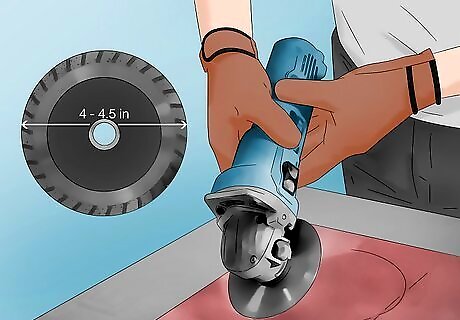

Opt for a 4 by 4.5 in (10 by 11 cm) grinder for most projects. You can find much larger grinders for projects, but this size will be fine for a variety of tasks, including most of the jobs you'll do in your home. Also, it's a common size, so look for it in most hardware stores. Plus, a larger tool is more difficult to handle, which can lead to injury if you're not careful.

Choose a 5-9 amp motor if you plan on using the grinder a while. If you want to use the grinder for a number of projects, try not to get the cheapest one. If you spend a little more, you can get a better quality machine. Pick a motor that pulls 5-9 amps, which will give you a little extra power and will likely stay in operation longer.

Check the RPM on accessories against the RPM on the grinder before buying them. All accessories will have a maximum RPM (rotations per minute). Exceeding that RPM could lead to the attachment breaking apart and sending flying pieces at you. Therefore, the RPM of the accessory needs to match or exceed the max RPM of the grinder. That way, if you turn your grinder to max, you still won't go over the max speed of the accessory.

Look for safety features like a wheel brake system. A wheel brake system will stop the grinder quickly if you need it to. Plus, it allows you to bring the grinder to a full stop before you set it down. Opt for a grinder that has this safety feature if you can. A grinding disc with noise reduction and a handle that reduces vibrations can also make your grinder safer.

Comments

0 comment