views

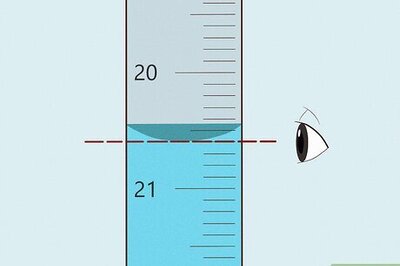

HYDERABAD: The AP Pollution Control Board has constituted a special Task Force team headed by senior environmental engineer, Siva Reddy, to streamline and regulate the activities of the spent solvent recovery plants in and around Hyderabad for a period of six months. “In chemical industries such as bulk drugs industry, various solvents are used for extraction of drugs. These solvents are distilled in distillation columns, and leave highly toxic residues which can be scientifically recovered. In case they are highly mixed, the only way to diffuse their toxicity is by destroying them completely, by incarcerating them in high temperature cement kiln industry," said Prasanna Kumar, of the APPCB. But with every industry seeking higher profits now-a-days, the need to destroy non-recoverable solvents took a backseat. Rather the spent solvents ended up as adulterant in regular fuels. “If you notice a thick black soot flowing alongside a newly tarred road it is because the tar is adulterated with spent solvents. Not just does this reduce the quality of the bitumen, but the solvent emits Carbon Monoxide gas, making it harmful for the environment”, said Prasanna. Keeping this problem of adulteration in mind, the board had permitted 25 recovery plants to function in and around Hyderabad for the scientific recovery and disposal of spent solvents. But apart from misusing solvents by mixing them with fuels, most of these units were found to be importing spent solvents from neighbouring states, thereby flouting safety norms set by the board, and were not disposing off the wastes properly either. It was in these contexts that finally the task force was formed to monitor the activities of the recovery plants and the industry in general. As part of the new regulations, APPCB also plans to strictly monitor the mandatory requirement for solvent recovery units to conduct mock drills once in six months, to help the industry handle emergency situations.

Comments

0 comment