views

Smartphones continue to evolve not just in terms of design or specifications but in terms of build as well. These days, many smartphones come with IP ratings for dust and water resistance, though the device promises to function in the harshest weather conditions. Oppo recently invited News18 Tech to the Oppo QE Reliability Lab in Greater Noida, Uttar Pradesh, to specifically highlight all that goes behind testing the durability of a smartphone. The results from these tests (some may even call a torture test) also help the company to perfect its future devices.

Oppo demonstrated all these durability tests on the Oppo F21 Pro that debuted in India recently and costs Rs 22,999. It chose this particular unit not only because it’s the latest in the market but to help us understand everything a smartphone can withstand when it measures barely 7.5mm in thickness and weighs 175 grams.

How the Smartphone Design Process Begins

Oppo explains that before the device goes into production, product designers are required to create “clear and detailed product blueprints” with enough information for factory workers to understand and follow accurately.

For instance, designers had to examine thousands of different textured materials for Oppo F21 Pro Sunset Orange’s distinct fibreglass-leather finish. In order to give the back cover of the phone an expressive textured effect that also feels smooth in the user’s hand, Oppo designers examined thousands of different textures. Eventually, the team of designers narrowed down thousands of potential materials to just six options. Its designers then narrowed down to just six options, and eventually selected a lychee grain leather texture due its suitable thickness and skin-friendly touch.

Aim of the Different Testing Methods

Now, there are multiple stages of tests to check the durability of a smartphone, in this case the Oppo F21 Pro. As mentioned, the company does not only test the external body but internal components as well to understand stress caused under different situations. Oppo explained that there are two sides to the testing programme. Some tests are run on every single phone, rooting out any defective components or manufacturing errors. Other more intensive testing happens at its QE Reliability Lab, where Oppo undertakes a kind of “torture testing” to compress the hard treatment of years of normal use into a much shorter time window.

In this quality testing process, all Oppo smartphones need to pass more than 320 experimental tests, and six major tests before they are ready for the next stage. Here are some key tests that Oppo undertakes at this centre:

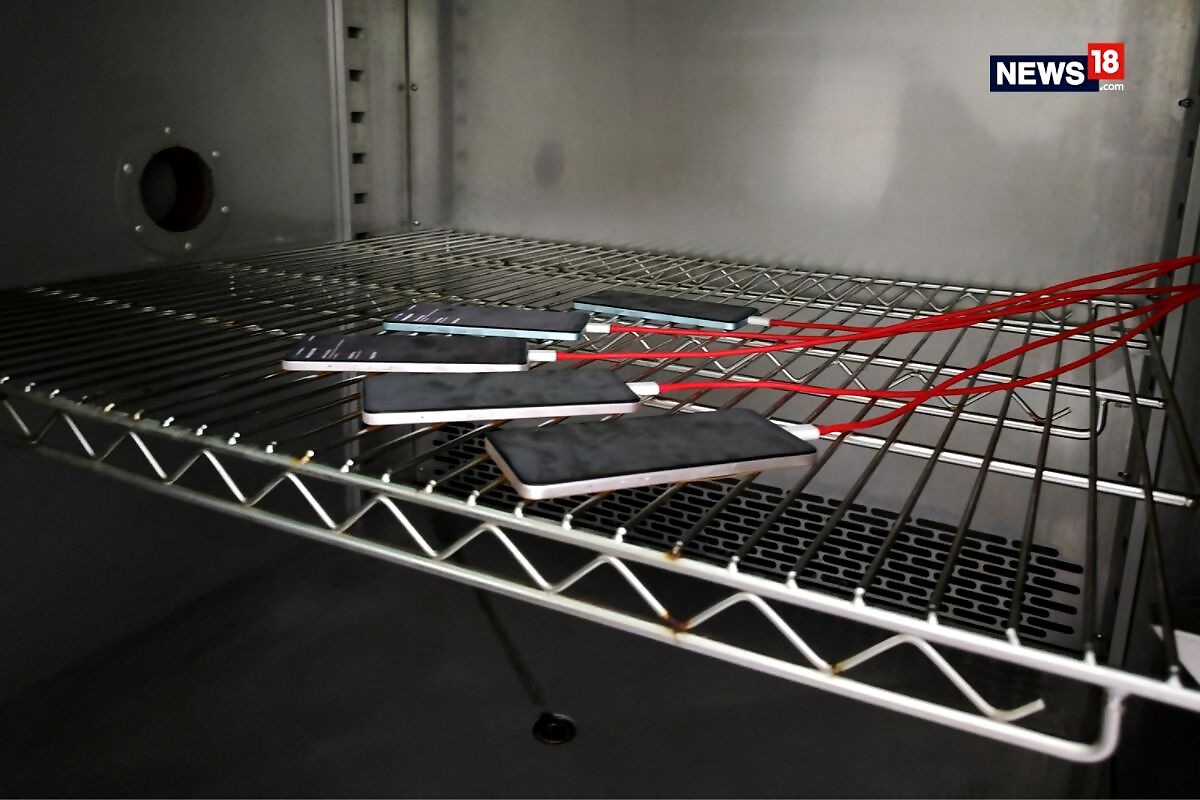

Temperature shock test: Its Environmental Work test involves storing the phone at a low temperature (up to -40°C) or in warm condition (75°C) for 14 days (300 hours). During this test the temperature changes every one hour to put the device in a temperature shock condition.

Storage and Ageing test: The phone is also tested at intense humidity and temperature (95 percent humidity at 65°C) for 14 days (336 hours), which is more than double the industry standard of 3 days (72 hours). This is tested both on a switch off condition and in a working condition to analyse all the functions of the device including camera, charging and others.

Salt spray test: This stage is mainly to understand the performance of the phone in coastal areas with high humidity and salinity. The Oppo F21 series was sprayed with a 5 percent salt solution for two hours before being stored in a hot and humid environment (50°C and 95 percent humidity). For the phone to pass the test, all functions must perform as normal, with all components intact and no signs of damage detected on the device’s surface.

Cosmetic and Sweat tests: Aside from harsh conditions resulting from the external environments, human sweat and cosmetics left on the phone surface by users could also cause damage to the phone. To test against these potential problems, OPPO F21 series was put through a Sweat Test and a Cosmetics Test.

We also witnessed the ‘classic’ tests you’d expect such as drop test, scratch test, and more. Here are some highlights that Oppo showcased:

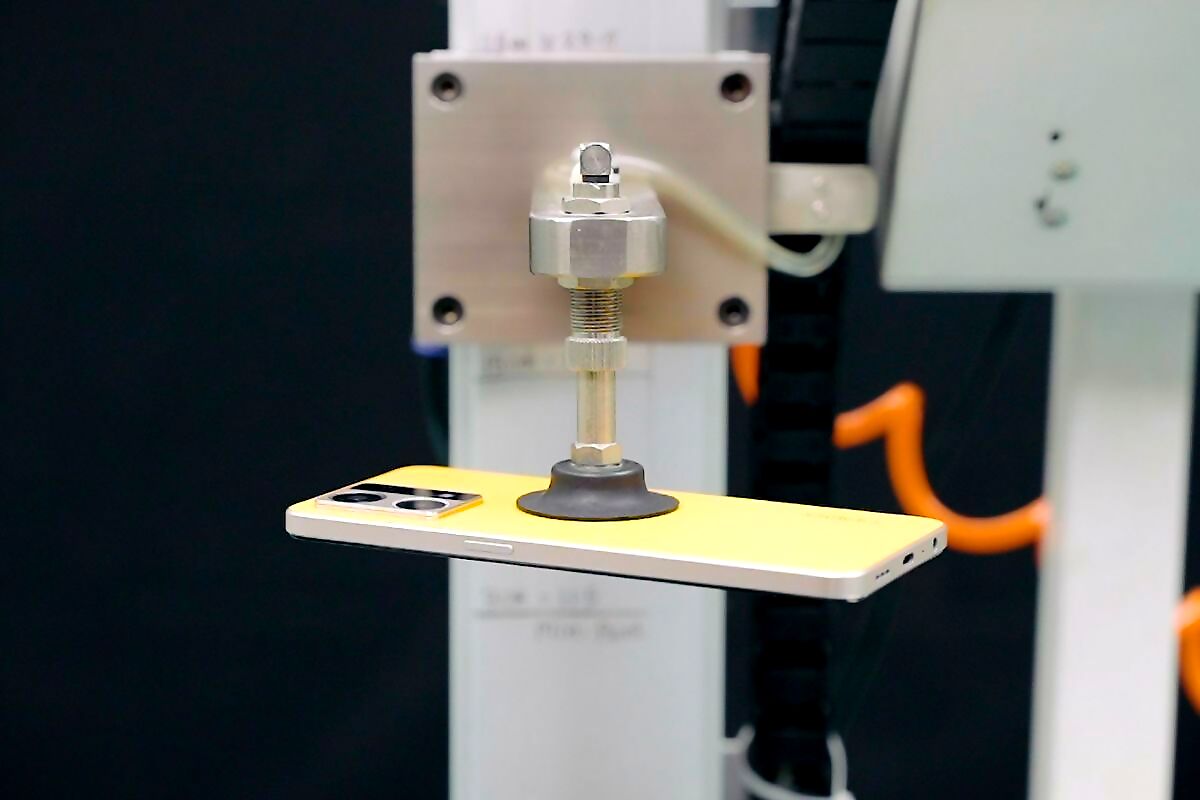

Drop Test: The Oppo F21 Series was dropped 28,000 times from a height of 10cm – which is considerably more than the 5,000-10,000 times typically adopted in the industry.

Micro Drop Test: Oppo tested Oppo F21 Series by dropping it on sandpaper – a material that seemingly simulates the roughest surface that a phone is likely to come into contact with during daily use. The company says it is the first phone manufacturer to adopt such a test for its smartphone products.

Tumble Test: In addition to these more common scenarios, F21 Series was also put through what is known as the Tumble Test to simulate the phone slipping and undergoing a strong collision. In the Tumble Test, the phone is placed inside a 1-metre-long case that rotates at a speed of 3.5 revolutions per minute for 15 revolutions.

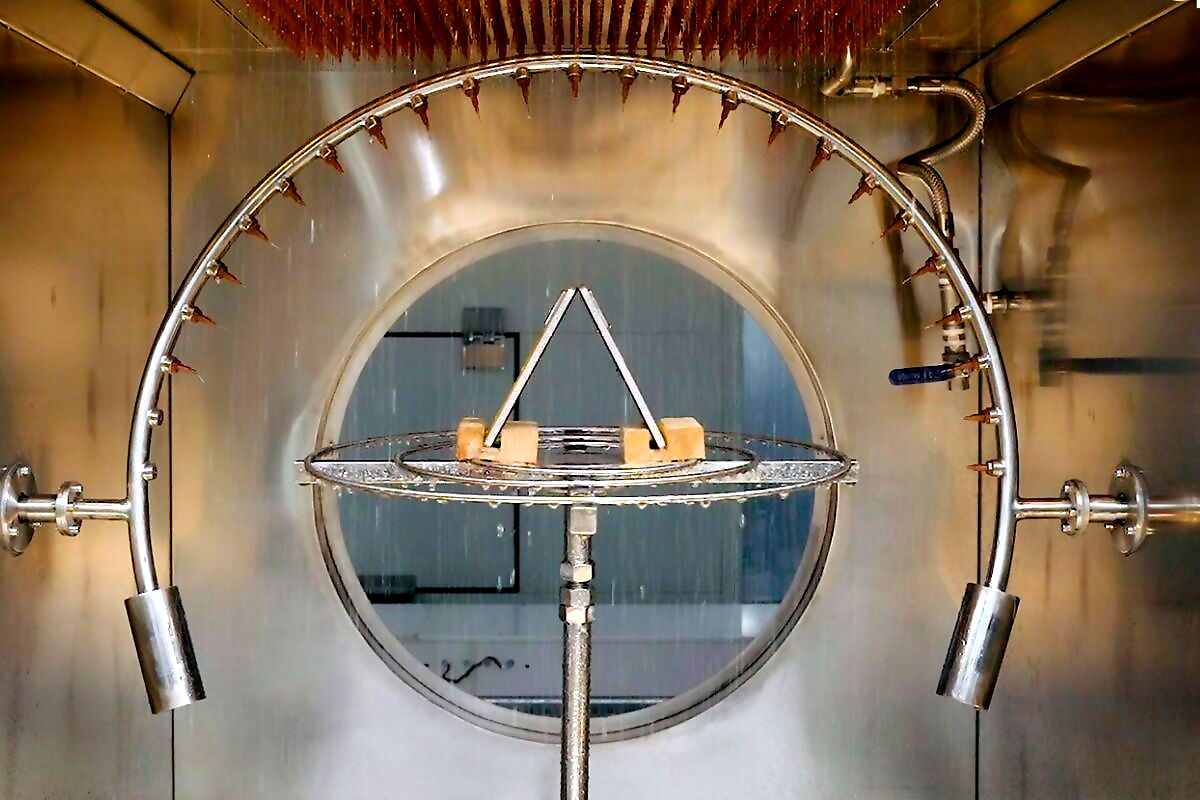

Waterproof Test: Lastly, the most visual test you’d find at the centre is the waterproof testing. Its Rain Test adopts the IPX4 standard (common industry standard for water resistance is IPX2), simulating a ‘heavy’ rainfall of 10 ± 0.5 L/min. During the test, the phone is sprayed with water onto its four surfaces at a 75° angle. It is also tested in the same way while the phone is playing video or making a voice call.

To further test the water resistance, OPPO F21 series was also tested underwater at a depth of 20 centimetres for 30 seconds

As expected, the results of the test help Oppo understand different stress situations for its device. If the smartphone clears these stress tests, the stage involves getting the device ready for end-customers.

Read all the Latest Tech News here

Comments

0 comment