views

- Make a 1-part soap, 10-parts water mix and add your construction silicone. Press your desired shape into the clay and wait a few hours for it to dry.

- Or, knead together 1-part silicone 2-parts cornstarch. Press your shape into the dough and wait just 20 minutes for your mold to dry.

- Alternatively, purchase a kit and follow the directions carefully. Typically, this process takes a few hours.

Using Silicone and Liquid Soap

Fill a bowl with water. The water should be about room temperature—not too warm and not too cold. It should be deep enough for you to stick your hand into.

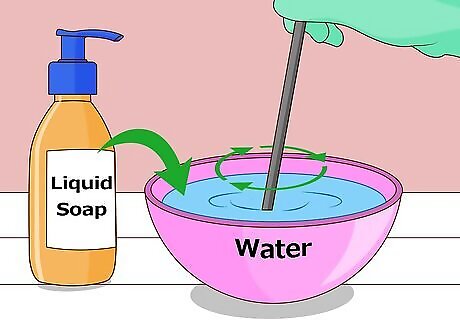

Stir some liquid soap into the water. You can use just about any type of liquid soap, including: body wash, dish soap, and hand soap. Keep stirring until the soap has completely dissolved and no streaks remain. Plan on using about 1 part soap to 10 parts water. You can also add liquid glycerin. The glycerin will react with the silicone and cause it to clump together.

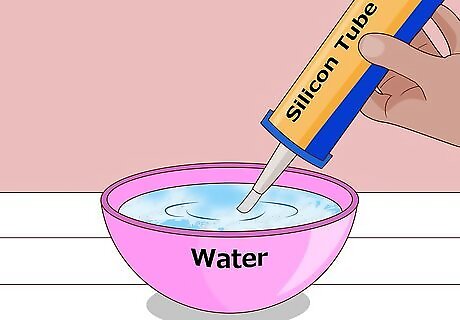

Squeeze some construction silicone into the water. Purchase a tube of pure silicone from the home improvement store; make sure it is not the quick-set kind. Squeeze enough of the silicone into the bowl to cover your desired item with. Construction silicone may also be labeled as silicone caulk. If your tube of silicone did not come with a syringe, you will need to purchase a caulking gun, insert the tube, cut the end off, then poke a hole in the tip.

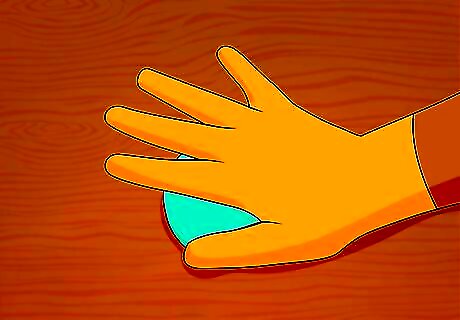

Knead the silicone while it is submerged. Put on a pair of plastic gloves, and reach into the water. Grab the silicone with your fist and squish it together. Knead it until it is no longer sticky while keeping it under the water. This will take about 5 minutes.

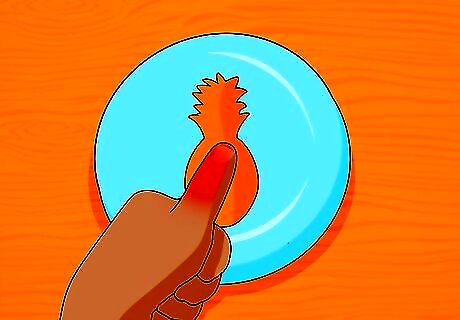

Form the putty into a thick disk. Begin by rolling the putty into a ball between your palms. Press it against a flat surface, and lightly push down on it. It still needs to be thicker than the item you will be molding. If the silicone is sticky, coat your hands and work surface with a thin layer of your liquid soap.

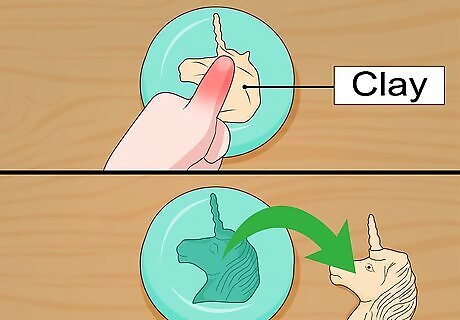

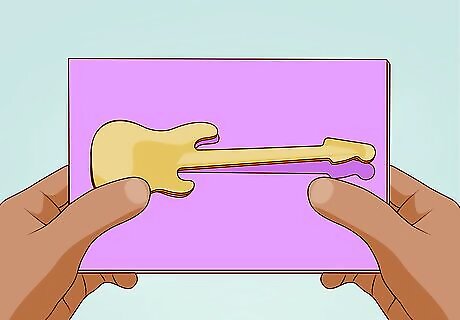

Press your desired item into the silicone. Make sure that you are pressing the item with the design side face-down into the putty. Gently press the edges of the mold against the item so that no gaps remain.

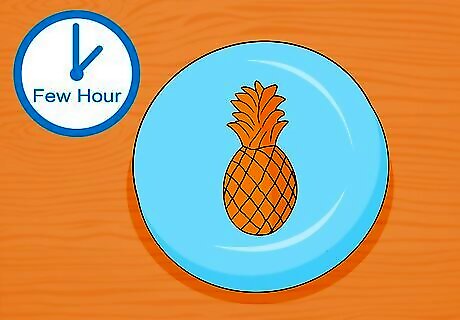

Let the silicone harden. Silicone will never turn rock-solid; it will always remain flexible. Simply wait a few hours for the silicone to turn rigid enough so that you can still flex it, but no longer dent it.

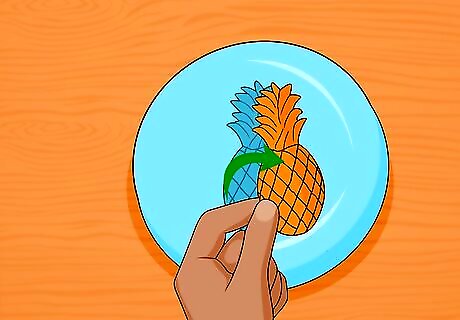

Pull the item out of the mold. Take the mold by the edges, and bend it backwards and away from the item. The item should loosen or pop out on its own. Tilt the mold upside-side to tip the item out.

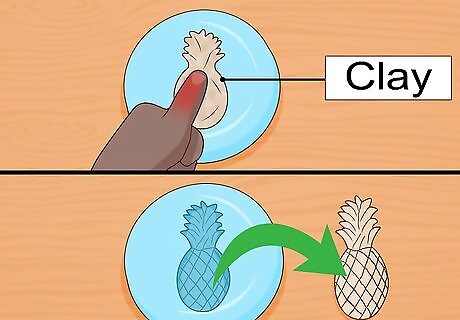

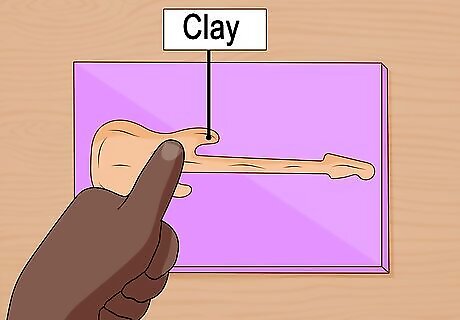

Use the mold. Fill the mold with clay, then pull the clay out, and let it dry. You can also try to use resin in this mold as well, but let it cure and harden first.

Using Silicone and Cornstarch

Squeeze out some construction silicone into a dish. Buy a tube of pure silicone from a home improvement store; it usually comes in a syringe-like container. Squeeze some of the silicone out into a disposable dish. You will need enough to cover whatever you wish to mold. You may also find construction silicone labeled as silicone caulk. Make sure that it is not the quick-set type. If the silicone did not come with a syringe, you will need to get a caulking gun first. Insert the tube into the gun, cut the end off, then poke a hole in the tip.

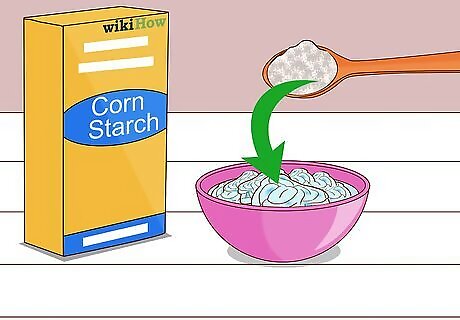

Pour in twice as much cornstarch. If you can't find any cornstarch, try cornflour or potato starch instead. Keep the box handy; you might need to use more. If you want a more colorful mold, add a few drops of acrylic paint. This will not make the mold any more or less effective.

Put on a pair of plastic gloves and knead the two together. Keep kneading until the silicone and cornstarch come together and form a putty. It may be dry and crumbly at first, but keep kneading. If it is too sticky, add some more cornstarch into it. You may have some cornstarch leftover in your dish; this is fine. The silicone will have picked up all the cornstarch it needed.

Roll the silicone into a disk. Start by rolling the silicone putty into a ball between your palms. Next, place it on a smooth surface, and gently press down on it to flatten it slightly. It still needs to be thicker than the item you wish to mold.

Press the item you wish to mold into the putty. Make sure that you are pressing it design-side-down into the mold, and that the back is visible. Use your fingers to push the edges of the mold against the item; you do not want to see any gaps.

Wait for the silicone to cure. This will only take about 20 minutes or so. You are ready for the next step when the mold is rigid. It should still be flexible, but you should not be able to dent it or form it.

De-mold your object. Hold the silicone mold by the edges, and gently bend it back and away from your item. Flip the mold over to pop the item out. If you need to, use your fingers to pry the item out.

Use the mold. You can push pieces of wet clay into them, then pull them out and let them dry. You can also pour resin into the mold, let the resin cure, then pop it out as well. De-mold any castings the same way you de-molded your initial object.

Using 2-Part Silicone

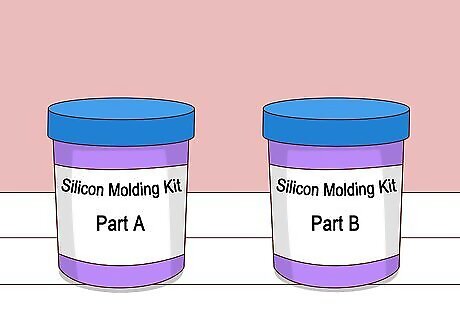

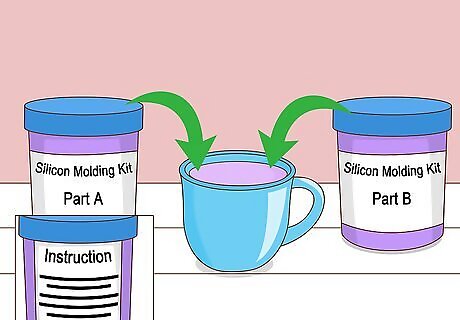

Purchase a mold-making silicone kit. You can find these in stores specializing in casting and mold-making supplies. You can also sometimes find these in a well-stocked arts and crafts store. Most kits will contain two containers labeled "Part A" and "Part B." Sometimes, you have to purchase them separately. Do not mix the silicone yet.

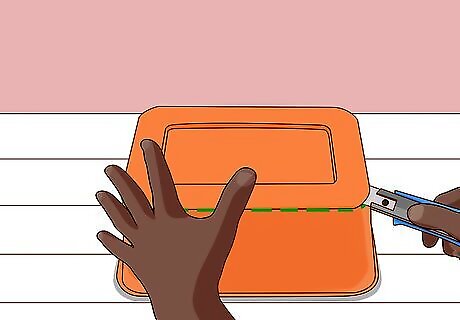

Cut the bottom out of a plastic food container. Find a cheap, plastic food container made from thin plastic. Use a craft blade to cut out the bottom. Don't worry about how neat or jagged it is; this will eventually be the top of your mold. Choose a container that is a little larger than the object you want to make a mold of.

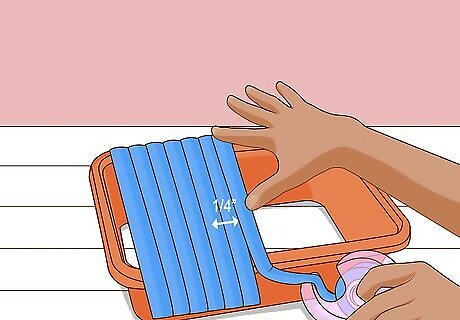

Place overlapping strips of tape over the top of the box. Remove the lid from the container. Cut several long strips of packaging tape, and lay them across the top. Overlap strip by about ¼ inch (0.64 centimeters). Leave a couple inches/centimeters of tape hanging over all sides of the container. Run your finger along the rim to create a tight seal. Make sure that there are no gaps, or the silicone will pour out.

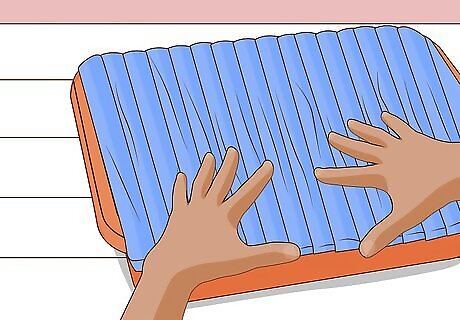

Fold the edges of the tape over the sides of the container. Once you fill the container with silicone, there is a small chance that some may leak out from under the tape. This will kept prevent the silicone from leaking out all the way and ruining your work surface.

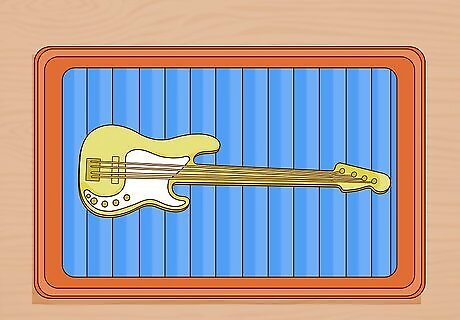

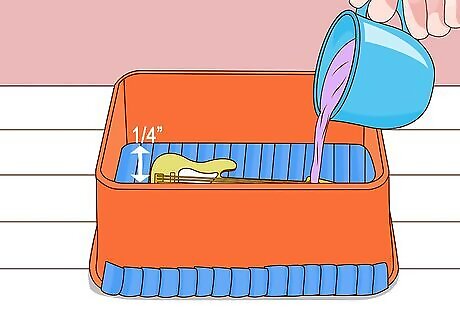

Set the item(s) you wish to mold into the container. Place the container onto a flat, stable surface with the cut/open side facing up. Place your items into the box, and press them against the tape. Do not let the items touch the side of the container or each other. Also, make sure that the design portion of your item is facing up, and the back is pressed against the tape. Flat-backed items work the best for this. Wipe the items clean beforehand, if necessary.

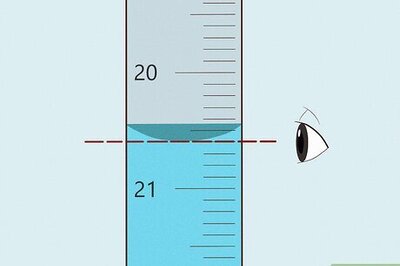

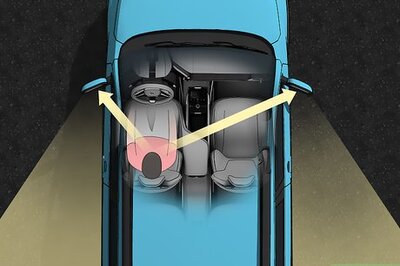

Measure out your silicone according to the manufacturer's instructions. You will always have mix Part A and Part B together. Some types of silicone are supposed to be measured by volume, while others need to be measured by weight. Read the instructions that came with your silicone closely, then measure them accordingly. Pour the silicone into the cup included with your kit. If your kit did not come with a cup, pour the silicone into a plastic, disposable cup. You need enough silicone to cover your items by ¼ inch (0.64 centimeters).

Stir the two parts until the color is consistent. You can do this with a skewer, a popsicle stick, or even a plastic fork, spoon, or knife. Keep stirring until the color is even, and no streaks or swirls remain.

Pour the silicone into the container. Use your stirring utensil to help scrape out any excess silicone so that you don't waste any. The silicone should cover the top of your item by at least ¼ inch (0.64 centimeters). If you make it too thin, the silicone mold may rip.

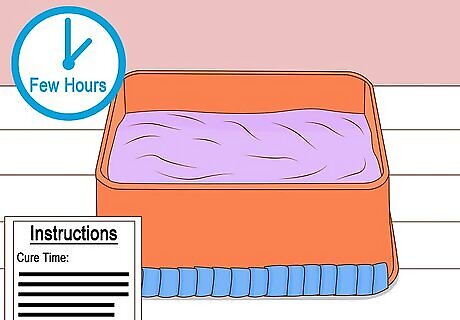

Let the silicone cure. How long this takes depends on the type brand you are using. Some brands are ready to use in a few hours, while others need to be left overnight. Refer to the instructions that came with your silicone kit for more specific curing times. Do not touch or move the mold during this time.

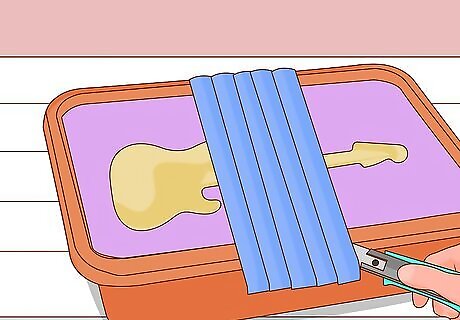

De-mold the silicone. Once the silicone has cured and turned rigid, peel the tape away from the box. Gently slide the silicone mold out. You may notice thin "feathers" if silicone around your mold. If these bug you, trim them off with a pair of scissors or a craft blade.

De-mold the items. The items you placed into the box will be stuck inside the silicone. Gently bend the silicone back to pop the items out. It is a little like remolding ice cubes from an ice cube tray.

Use the mold. You can now fill the cavities with resin, clay, or even chocolate (if the silicone was food grade). If you used clay, you can pop the pieces out while the clay is still wet. If you used resin, however, you must allow the resin to cure completely before removing it.

Comments

0 comment