views

Removal

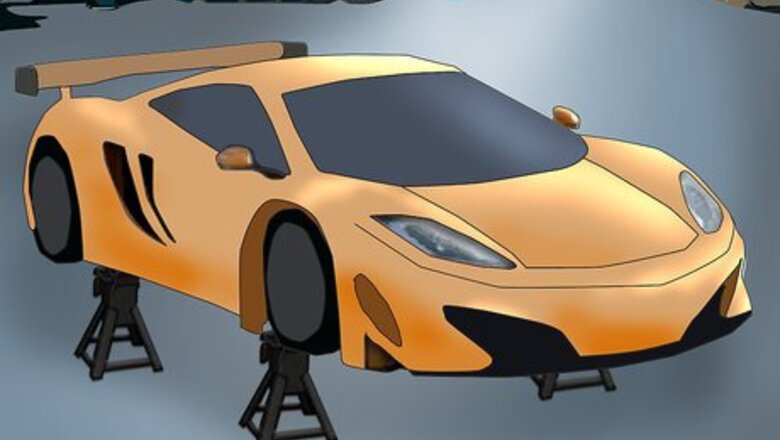

Park in a level place and jack the vehicle up at all four wheels and support on jack stands. Replacing your vehicle's catalytic converter isn't quite like replacing a tire — you'll need to raise the entire vehicle off of the ground, rather than just one corner. It's very important to find a level spot to do this maintenance on your car. If your car is not stable, you risk serious injury or death if your jacks fail. If you have access to a professional-quality hydraulic lift and know how to safely use it, this is also an acceptable way to lift your car when replacing the catalytic converter.

Allow the vehicle's exhaust to cool down. If your vehicle hasn't had an opportunity to cool down after running, its exhaust system can still be quite hot. To reduce the risk of painful burns, give your vehicle a chance to adequately cool down before working on it. Depending on your vehicle's exhaust system, this will usually be a matter of just a few minutes. To test the heat of the exhaust system, put on a pair of heavy mechanic's gloves and gently brush the exhaust tube with the back of your hand. If you can't feel any heat, you may cautiously repeat this test without the glove.

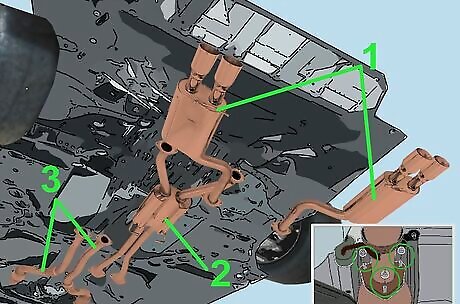

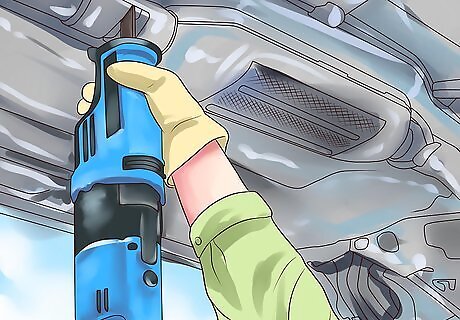

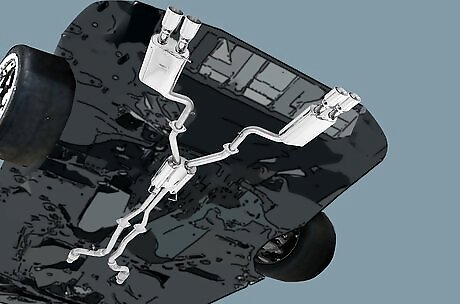

Locate the catalytic converter. Slide under the vehicle and locate the tubes of the exhaust system, which should run all the way to your vehicle's rear exhaust. The converter should not be terribly difficult to find — it will usually take the form of a rectangular or rounded "box" in the middle of your exhaust system. Some models can have a roughly cylindrical shape. Check to see whether the converter is bolted or welded to the rest of the exhaust system at its connection points. You may need to take it to an auto shop to have it repaired if it has already been replaced and welded back into position, rather than bolted. You can still replace a welded converter if you have access to a sawzall (or similar tool) and a welding machine and know how to safely use both, but these advanced tools are beyond the mastery of most amateur mechanics.

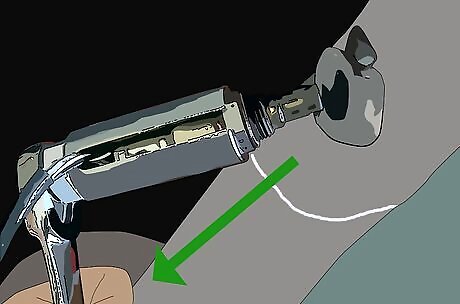

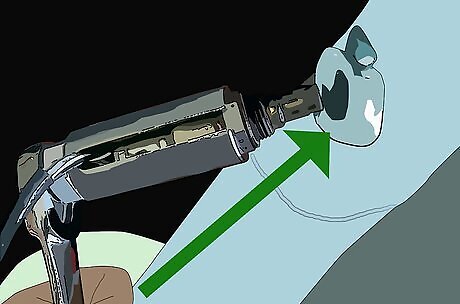

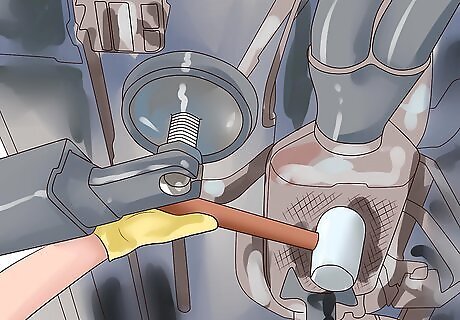

Remove the O2 (oxygen) sensor from the catalytic converter. Most modern catalytic converters are equipped with one or more oxygen sensors that monitor the efficiency of the car's exhaust system continuously. If your catalytic converter has an attached oxygen sensor, use an oxygen sensor socket and a ratchet wrench to disconnect it before proceeding. When you're done, move the sensor out of your way so that it doesn't interfere with the rest of the process.

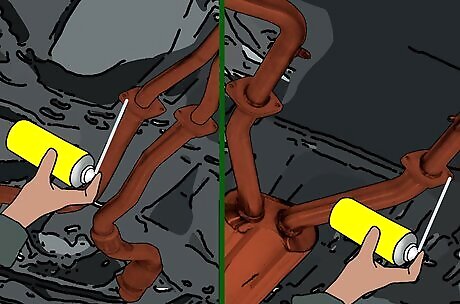

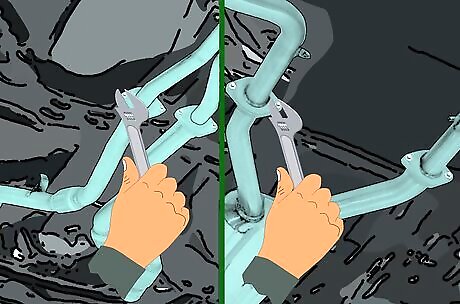

If bolted, apply penetrating oil to the bolts. Catalytic converters that are bolted in can sometimes have bolts that are rusted, partially-corroded, or "jammed" into their nuts. These bolts can be very tricky to remove, so loosen them up by applying a penetrating oil (available from most auto stores). Allow the oil to seep into the bolts and lubricate them for several minutes before attempting to remove them.

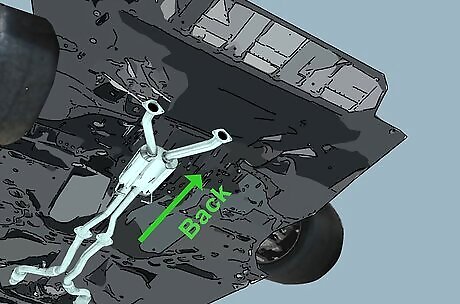

Remove the bolts at the back end first, then at the front. Use an appropriately-sized wrench to begin loosening all of the bolts before you start removing them. Once all of the bolts are loosened (but still attached), remove the "rear" bolts (those closest to the open end of the vehicle's exhaust) before removing the "front" ones (those further away). Remove the converter when you're done. You may have to support the exhaust once the converter is removed.

Alternatively, for welded-in converters, cut the converter out. If your converter is welded into the rest of the exhaust system, rather than bolted in, the only way to remove it is to physically cut it out of the pipes it's connected to. Most mechanics will use a sawzall or similar tool for this purpose. Cut along (or near) the existing weld lines, then remove the converter after it's cut free. If you finish and the converter won't seem to budge, you may want to use a hammer to knock it out of its place as long as you take care not to damage or rattle any other parts of the exhaust system (this can lead to harmful exhaust leaks down the road).

Installation

Always defer to any included instructions. The instructions provided in this article are written for general cases of catalytic converter installation. Because the exact part needed and the installation process can vary from vehicle to vehicle, the steps you’ll need to replace your vehicle’s converter may be different than the ones here. When in doubt, always follow the instructions provided with your replacement part or consult the advice of a knowledgeable mechanic. Converters have a specific direction they should flow and have an arrow for direction of exhaust flow.

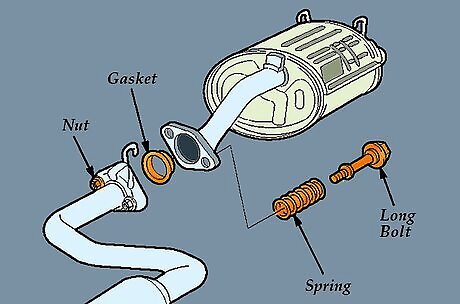

Insert any gaskets supplied with the new catalytic converter. Some converters, especially bolt-installed ones, will come with small, round gaskets that sit in the pipes connected to the converter to give the converter a snugger, more secure fit. If your replacement converter came with these gaskets, install them according to any provided instructions before proceeding.

Put the new catalytic converter in place. Next, hold the catalytic converter in the position where it will eventually be installed. Double check to make sure it is pointed in the right direction (there should be an arrow indicating this) and that the correct side is facing down. Since it's tricky to work on the converter with one hand while you hold it in place with another, for the next few steps, it can be useful to enlist a willing friend to hold the converter in place while you work or use a stand to hold it up in place.

Finger-tighten nuts on the bolts. If your vehicle's catalytic converter was bolted in and your replacement converter has bolt holes that match your exhaust system's, installation is usually a cinch. To start, re-insert your bolts and use your hands to manually tighten them. This makes it easier to get all of the bolts to align correctly because the looseness gives you a small degree of "wiggle room" to make minor adjustments as needed.

Tighten down all the bolts. Starting on the "front" end of the converter (the end further away from the vehicle's exhaust), tighten the bolts with a suitably-sized wrench. Proceed to the back end when you finish tightening the bolts on the front. You'll want your bolts to be very tight. Most exhaust leaks are caused by loose bolts, so making sure your bolts are extra tight now can save you headaches in the future.

Alternatively, weld the converter into place. If you need to weld your converter into place, the process is somewhat more involved. You'll need a professional-grade welding machine (such as a MIG welder) and the proper training and expertise required to use one safely (or a friend who has these things). Don't attempt to weld your converter back into place if you're not a competent welder — you could damage your vehicle or even hurt yourself. Weld your converter into place by carefully joining it to the exhaust system pipes at either end. Be sure to create a secure, air-tight seal at each weld. If the pipes aren't wide enough, you may need to heat them up and flare them to make them fit. If your pipes don't quite reach one end of your converter, you may need to weld an additional extender pipe in. Sometimes you have to do a partial weld then lower the exhaust to finish the top part of the weld. Be sure to allow your welds to cool to a safe temperature before proceeding.

Screw the oxygen sensor back into place. If you originally removed one or more oxygen sensors to access your converter, replace them now. As you do, check to make sure that the attached wiring is secure and is not frayed or damaged — this can lead to inaccurate readings and even false "check engine" lights.

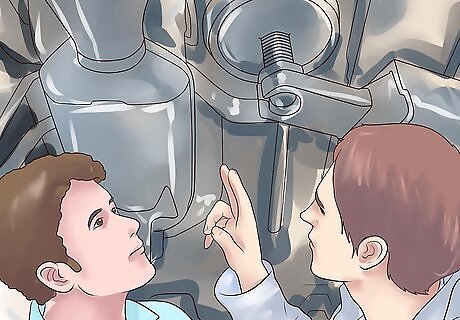

Double-check your work. At this point, if you've done everything correctly, you're basically done. Take the opportunity to make sure one last time that the catalytic converter is connected correctly and there are no gaps or leaks at either of the connections or the oxygen sensor. If you bolted your converter in, make sure all of your bolts tight. If you welded it in, make sure your welds are sturdy and airtight.

Testing

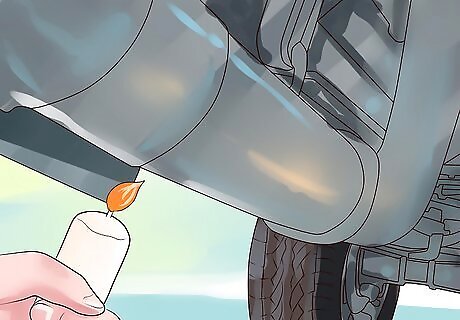

Check for exhaust leaks. Once you've installed a new catalytic converter, one thing you'll want to do immediately is double-check to make sure there aren't any leaks in the exhaust system on either side of it. Depending on where it is, an exhaust leak can cause a variety of problems for your vehicle, including reduced fuel efficiency and long-term damage. There are several ways to find an exhaust leak. One is to simply be observant while you drive — if your car sounds louder than normal when it runs or seems to "rumble" more, you may have a leak. You can also check for leaks by jacking your car up, starting it in park, and carefully moving a lit candle along the length of the exhaust tubing. Leaks which are invisible to the eye should cause the flame to waver or blow out.

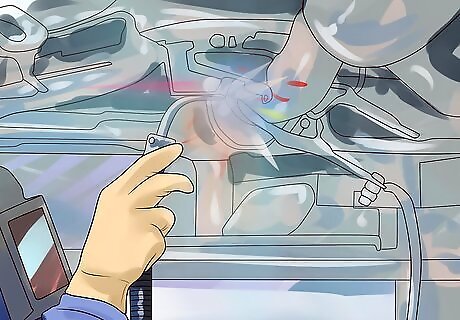

Measure back-pressure in the exhaust system. One problem that can occur in faulty catalytic converters is that they can become "backed up" with soot, debris, and other exhaust byproducts or broken apart inside the converter. In this case, the engine's ability to rid itself of exhaust is hampered, which can cause a vehicle's fuel efficiency to plummet and can even cause the engine to stall in severe cases. Luckily, performing a backpressure test is simple — just screw a pressure gauge into the oxygen sensor's hole before the converter in the exhaust manifold in most vehicles. The pressure reading should be less than 1.25 psi when the vehicle's engine is running at 2,000 RPMs. The worse the congestion is, the higher the pressure reading can be. Very bad backpressure readings can approach 3 psi.

Perform a mallet test for old converters. If your car's converter is old and worn, one simple test can tell whether it needs to be replaced very quickly. Simply grab a rubber mallet (or similar tool) and give the converter a firm hit. If you hear any sort of rattling, your converter needs to be replaced — this indicates that the metallic catalyst within has begun to corrode and crumble. However, if you don't hear a rattle, this doesn't necessarily mean that your converter works well. There may still be other problems with it. To be clear, this test can only tell you if you have a bad converter, not if you have a good one.

Consider more advanced tests. Catalytic converters can be tricky parts — if you're in doubt about whether or not yours is functioning properly even after performing the tests above, don't hesitate to take it to a mechanic or specialist. These professionals will have access to the type of equipment that can be used to perform more advanced tests, like delta temperature tests, oxygen storage tests, and CO2 tests. Most auto shops that offer smog testing will be able to perform these sorts of emissions tests.

Comments

0 comment