views

X

Research source

Selecting Your T-Shirt Design

Select a plain, clean, unwrinkled T-shirt to screen print a design onto. Avoid laundering your shirt with fabric softener or dryer sheets, as it may keep the ink from setting into the shirt. Lay the shirt out on a flat surface to keep it from becoming wrinkled. If there are folds or wrinkles in your shirt, this may negatively affect the transfer of the design onto the shirt. Iron the shirt as needed until the fabric is smooth.

Find or draw a black-and-white image to use for your T-shirt design. Keep the T-shirt design simple, like a silhouette, if this is your first time screen printing. The image must be black-and-white in order to transfer the design onto the screen. As you become more experienced, try to integrate more complex black-and-white designs. For example, incorporate a paint splatter or a motorcycle into your T-shirt design. If you find an image online that you want to use that is not black-and-white, then use a program, like Photoshop, Microsoft Word, or Microsoft PowerPoint, to alter it. If you draw the image by hand, outline it with a thick black marker and scan it to your computer.

Print the black-and-white design onto a clear transparency sheet. Take out any paper you have normally loaded into your printer, and replace it with the transparency sheet. Double-check that your image is black-and-white, and then print it. Depending on your printer, you may need to change the paper settings so your printer knows that it is using something other than paper. Consult your printer’s manual or the manufacturer’s website on how to do this. While screen-printing is a bit more labor intensive than ordering a print-by-demand T-shirt online, it gives better design results and lasts longer over time.

Setting up the Silkscreen

Set up your workstation in a dim room and cover it with newspaper. Clear a large, flat surface for you to work on. Then, cover it with newspaper to protect the surface from the harsh chemicals. Close any curtains or doors that filter in sunlight, as the UV light can prematurely harden the emulsion chemical you will be working with. If you do not have enough newspaper to cover your workstation, use an old sheet or tarp.

Mix some emulsion and sensitizer according to the manufacturer’s instructions. Screen printing uses emulsion and sensitizer to transform the silkscreen into a stencil with your design on it. When mixed together, these chemicals will harden when exposed to UV light. This is a chemical process called photo emulsion. Since instructions can vary between brands, make sure you carefully read the instructions listed on each bottle before attempting to mix the chemicals together. Wear rubber gloves at all times while working with these chemicals. Use a disposable utensil, like a plastic spoon or a chopstick, to stir the mixture. You can purchase emulsion and sensitizer at a local photography or print shop, or you can order it online through major retailers.

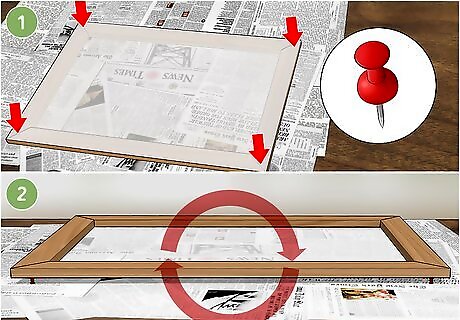

Elevate a silkscreen by placing a pushpin into each corner on the flat side. A silkscreen is a wooden frame that is covered with thin mesh. After being covered with emulsion, your silkscreen will become a stencil for your T-shirt design. To elevate the flat side of the silkscreen, grip the frame with one hand, and push a pin into the corner of the frame. Repeat this process for the other 3 corners. Then, place the frame on your working surface, so that it is resting on the push pins. This will allow you to fill the well of the frame with the emulsion you just mixed. Don’t worry about putting push pins on the side of the silkscreen with the well, as that side is already elevated enough so the mesh does not touch the surface you are working on. You can purchase a silkscreen frame at a local art supply store, or order it online through major retailers. If your selected design is small enough, you can also use an embroidery hoop fastened with a thin mesh material to use as a quick DIY alternative. The process of using the embroidery hoop is the same as a standard silkscreen frame, but just on a much smaller scale.

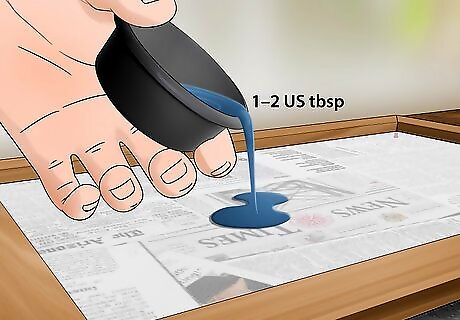

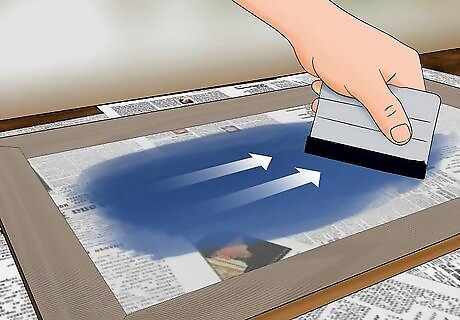

Put 1–2 US tbsp (15–30 mL) of emulsion into the well of the frame. Don’t worry about having exact measurements for this. You may need to add more emulsion onto the screen as you begin to spread it out.

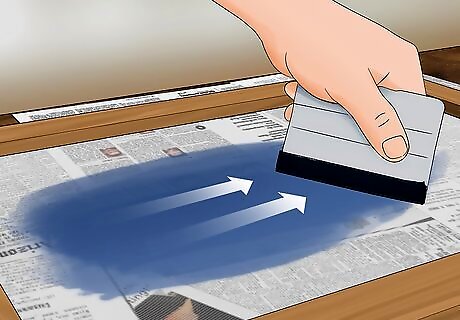

Use a squeegee to spread the emulsion over the screen. Slowly push the emulsion around the screen with the squeegee to create a thin coating. Apply a gentle pressure when doing this. Try to cover the center portions of the screen first, and then rotate the frame as needed to push the emulsion to the edges of the screen. If needed, add small amounts of emulsion onto the screen until it is completely coated. Just be careful not to use too much emulsion; otherwise, it may drip off the screen and put bumps in your coating.

Flip the frame over and cover the flat side of the screen with emulsion. Be careful not to touch or bump the side of the screen with the emulsion. Then, pour approximately 1 US tbsp (15 mL) of emulsion onto the flat side of the screen, and use the squeegee to spread it. The flat side of the screen will most likely take about half as much emulsion to coat it. If you notice any drip marks on either side of the coated screen, use the squeegee to smooth them out. It is important for the emulsion coating to be smooth; otherwise, the imperfections with transfer onto your T-shirt design.

Rest the screen on the pushpins and leave it to set in a dim space overnight. Either leave the screen to set in the room you are working in, or place it in another dim space where it won’t be disturbed. If you move the screen elsewhere, place a piece of newspaper or cardboard underneath the screen in case it drips. Speed up the drying process by placing a fan near the screen. Cover the frame with a thick, dark fabric if you have to transport it through areas that contain UV light.

Exposing the Emulsion to Light

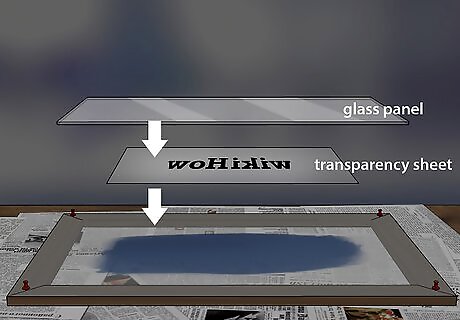

Place the transparency sheet and a glass sheet onto the flat side of the frame. Make sure that the room you are working in is still dim. Put the transparency onto the center of the screen. Then, carefully layer the sheet with a piece of clear glass. The glass will help keep the transparency sheet flat against the screen. If your image is not symmetrical, lay the transparency sheet onto the screen so the image appears backward. This is incredibly important for text-based images. Otherwise, the image will print backward onto your shirt. Instead of purchasing a special sheet of glass, use the glass from an old picture frame. To help speed up the exposure process later, spread out a piece of thick, dark fabric underneath the screen. The dark fabric will absorb UV rays and reduce reflection.

Position a light source in the “off” position, above the layered frame. Use any transportable lamp that has a 250-watt light bulb in it. Move the light source as needed so that it will spread light evenly over the screen—approximately 18 in (46 cm) above the screen. The light will harden the emulsion that is not blocked by your T-shirt design. The exposure process can also be quickly accomplished by placing the frame outside in the sun. If you are planning on transporting the frame outside, make sure to completely cover the emulsion and the silkscreen frame with an opaque object, like a thick piece of cardboard or dense fabric.

Expose the emulsion to the light according to the manufacturer’s instructions. Read the instructions for your particular brand of emulsion carefully before turning on your light source. The exposure times can vary greatly between brands and light source intensity. It can take anywhere from 1 minute to 1 hour for the emulsion to harden. Generally, the emulsion will have a darkened-appearance when it is fully hardened.

Spray the screen with cold water until all of the wet emulsion is removed. Quickly take off the glass and transparency sheet. Then, use a garden hose with a spray nozzle or a shower hose to remove the wet emulsion that was blocked by the design on the transparency sheet. Continue to spray the emulsion until a stencil of your design is visible on the screen. If you need to take the silkscreen frame outside to hose it down, try to have the hose set up ahead of time. This way, the sunlight does not harden the wet emulsion that needs to be removed.

Allow the screen to air-dry for 30 minutes before using it further. Use a clean cloth to pat excess water from the screen. Then, lay it flat and let it air-dry for about 30 minutes or until it is completely dry.

Transferring the Design onto Your T-Shirt

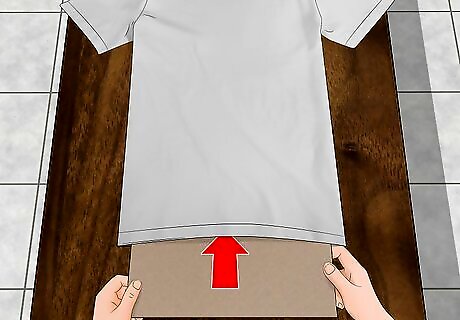

Slip a piece of cardboard into your shirt to keep the fabric layers from touching. Size the cardboard so it is as wide as your T-shirt. This will prevent the screen printing ink from staining the back of your T-shirt.

Position the flat side of the screen against the front of your T-shirt. Place the image in the upper center portion of the shirt for a traditional look, or place it off-center for a less conventional design. Just make sure that the fabric underneath the screen is not bunched or wrinkled; otherwise, the screen printing ink will leak out of the stencil. If you want the image on the back of your T-shirt, then rest the flat side of the screen against the back of your shirt instead. Look down inside the well of the silkscreen frame. Any text or non-symmetrical designs should be facing the correct way.

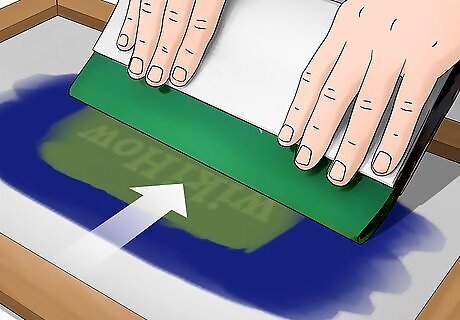

Put 1 tablespoon (15 mL) of screen printing ink above your design. Arrange the ink so that it is a line that is the same width as your design. This will make it easier to pull the ink down evenly over the stencil. Purchase screen printing ink at a local craft store or print shop, or online with major retailers.

Use a second, clean squeegee to pull the ink across your design. Pull the ink in a single direction to ensure that you create a smooth, thin layer. Continue to pull the ink over the design until it is evenly dispersed. For larger designs, add more ink if needed. Just be careful not to oversaturate your fabric with ink, as it might begin to bleed outside of the stencil.

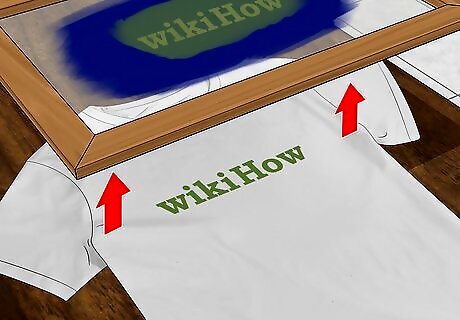

Remove the screen from the T-shirt and allow the ink to dry before setting it. Lift the screen straight up from the T-shirt. Be careful not to jostle the fabric as you do this. Then, refer to the manufacturing instructions on your particular screen printing ink on how long to let the ink air-dry. Generally, the ink will take 30-60 minutes to dry.

Set the dried ink with heat to permanently press the design onto the T-shirt. Refer to the manufacturing instructions on the screen printing ink to see which method is best recommended to set the ink. Ironing is the most common method of setting screen printing ink. However, some brands may require you to expose the shirt to sunlight or set in a dryer. Reuse the silkscreen frame to print the design onto other T-shirts or fabrics or get a new silkscreen frame to make new designs.

Comments

0 comment