views

- Mark and install post holes and line posts. Then, add bands and caps to the posts.

- Install the top rail by feeding the rails through the loop caps. Then, insert the rail ends into the terminal rail caps and tighten the nuts and bolts.

- Slide a tension bar through the starting end of the mesh fencing and bolt 1 end to the terminal posts’ bands. Then, unroll, stretch, and attach the remaining mesh to your posts.

Preparing to Install the Fence

Obtain any necessary permits. Your local government may have building and zoning regulations that regulate fence setbacks, type, and height. If you install a fence without a permit, they may tear down the structure.

Establish where your property lines are located. This information can be obtained from city records, a realtor's line plot map, or by hiring a surveyor.

Find out where your utility lines are. Have your utility companies mark the location of your utility lines. You don't want to accidentally hit them while digging post holes. You can call 811 from anywhere in the US. Your local utility companies will then send an employee to mark your utility lines for free.

Review any neighborhood covenants for regulations on fencing. Some neighborhood associations have their own rules regarding height and style, additional to the rules enforced by your town.

Marking and Installing Terminal Posts

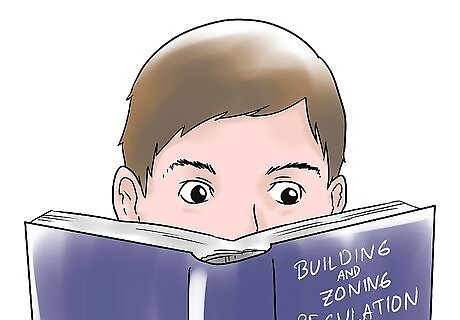

Locate the property lines that border your neighbor's. For your post holes, measure approximately 4 inches (10.2 cm) inside those lines. This prevents the concrete footings from encroaching onto your neighbor's property. Clear the working space along the entire length of the property line to make it easier to move a wheelbarrow, as well as for rolling out the fence for installation.

Measure the total length of your planned fence. This determines how many feet of chain-link mesh and the amount of hardware you'll need. Consult your local retailer for post spacing guidelines to determine the number of posts you'll need.

Find each terminal post location. Mark the exact spot with a stake or spray paint. A terminal post refers to any end, corner or gate posts. Spray paint works best as stakes will create a possible tripping hazard and can cause injury.

Dig all the terminal post holes first. Post holes should be dug 3 times the width and one-third the length of the post, with an extra 4 inches (10.2 cm) for gravel. Slope the sides so that the hole is wider at the bottom than at the top.

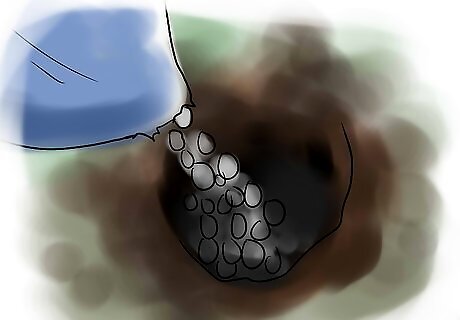

Fill the post holes with 4 inches (10.2 cm) of gravel. Tamp down the gravel to provide a compact foundation for the posts and concrete.

Stand a terminal post in the center of its hole. Mark the side of the post at ground level using a marker or chalk. The height above the line should equal the height of the fence mesh, plus 2 inches (5.1 cm).

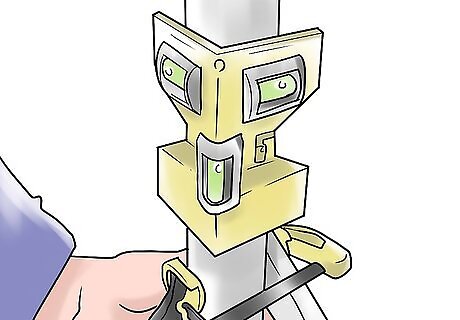

Plumb the post. Plumbing a post helps keep your fence looking straight. Using a carpenter's level or plumb line to check the balance, position the post until its plumb.

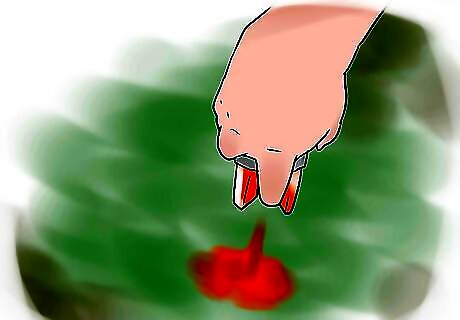

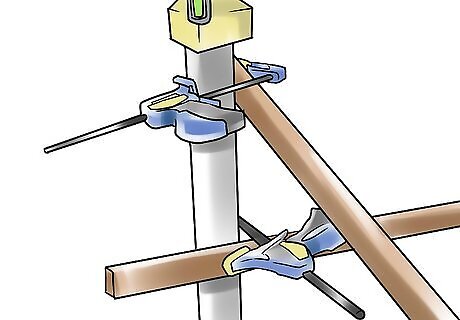

Secure the post in position. Using clamps and pieces of 1" x 4" x 4' to 6' long lumber angled on two sides, brace the post in its plumb position by using wooden stakes driven into ground and screws. Double check all measurements, post spacing, and height one last time before securing it to the bracing material because you do not want it to be even slightly out of alignment when the concrete hardens.

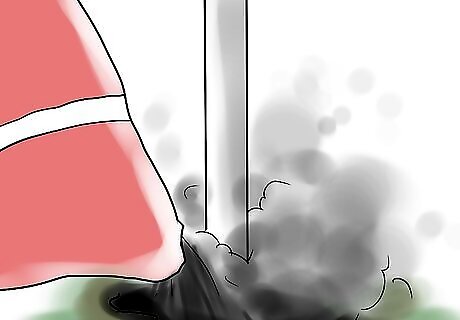

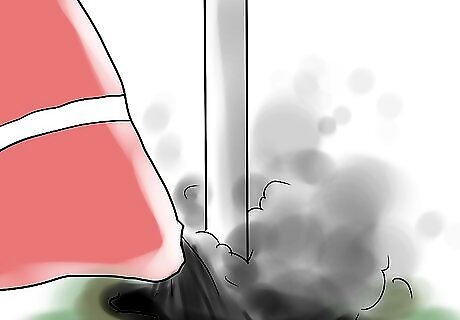

Fill the hole with concrete. Pour or shovel concrete around the post. Smooth the surface with a trowel or small piece of wood, sloping away from the post to direct water elsewhere.

Repeat until all your terminal posts are installed. Allow time for the concrete to set, according to manufacturer's recommendations. Allow at least 24 hours at minimum before putting tension on posts.

Marking and Installing Your Line Posts

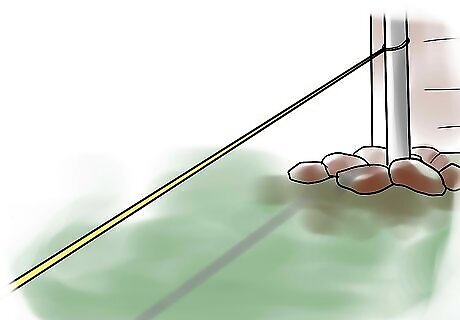

Run a string line between the terminal posts. The string should be taut, low to the ground, and positioned on the outside face of the terminal posts.

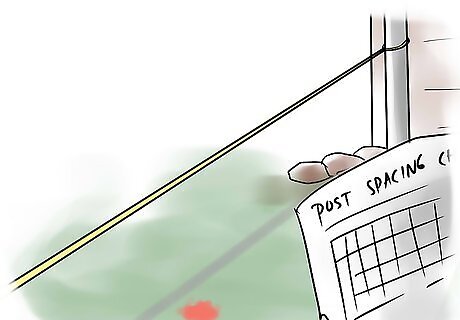

Mark the location of each line post. Using a post spacing chart, measure and mark the exact spot with a stake or spray paint.

Dig the line post holes. Line post holes should be 6 inches (15.2 cm) wide and 18 inches (45.7 cm) to 24 inches (61.0 cm) deep, with sloping sides. Right before installing line posts, you can run a second, very tight line from terminal posts to set the height of line posts, but always re-check all measurements before final bracing.

Fill the line post holes with 4 inches (10.2 cm) of gravel. Pat down the gravel to provide a compact foundation for the posts and concrete.

Position a line post in the center of its hole. Use a marker or chalk to mark the side of the post at ground level. The height above the line should equal the height of the fence mesh, plus 2 inches (5.1 cm).

Make sure your post is plumb. Go around the post with your carpenter's level or plumb line, checking to see if the post is balanced. Continue moving the post until it's plumb.

Secure the post in the plumb position. Add clamps and long pieces of lumber that are angled on two sides to hold the post in its plumb position. Use wooden stakes in the ground as well as screws to brace the post. Before securing the post, double check that it's straight.

Pour in the concrete. Smooth over the surface of the concrete with a trowel or small piece of wood. Create a slope in your concrete so that water will slide down away from your fence post.

Continue until all of your line posts are installed. Allow time for the concrete to set, according to manufacturer's recommendations. Allow at least 24 hours at minimum before putting tension on posts.

Add Bands and Caps to the Posts

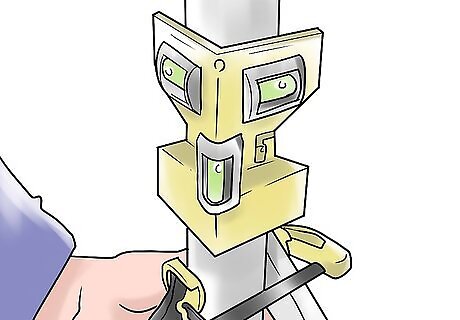

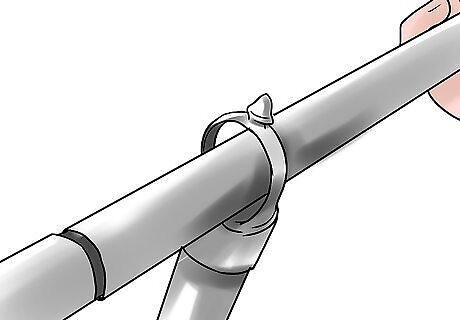

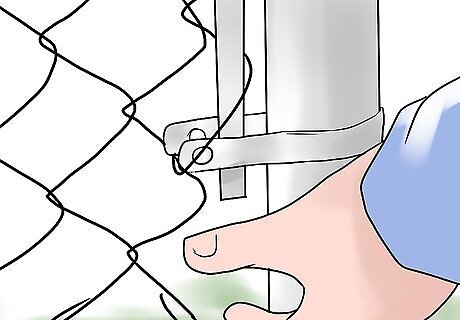

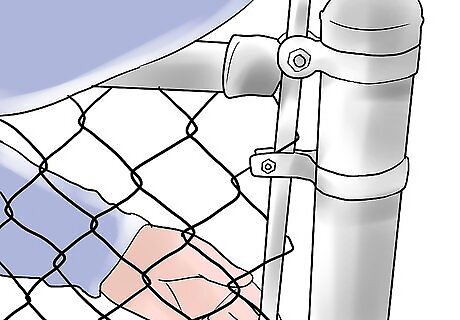

Slide tension bands onto each post. Tension bands secure the chain-link mesh to the posts. Use one less tension band than the height of the fence, in feet. For example, if the fence is 4-feet high, use 3 tension bands per post. For a 6-foot fence, use 5 bands, and so on. The long, flat surface of the tension band should face toward the outside of the fence.

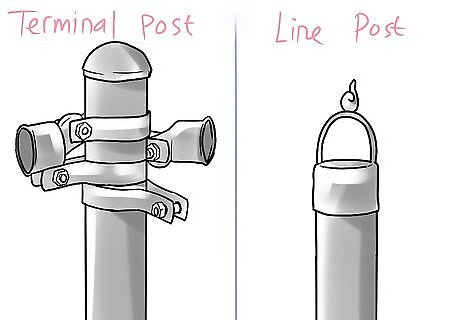

Add the appropriate caps to posts. Terminal posts get end caps. Line posts get looped caps (for the top rail.)

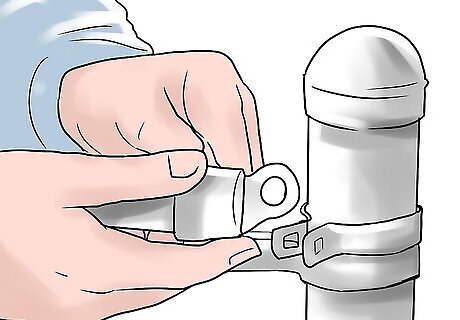

Tighten all the nuts and bolts, but not too tight. Leave some slack for adjustments.

Install the Top Rail

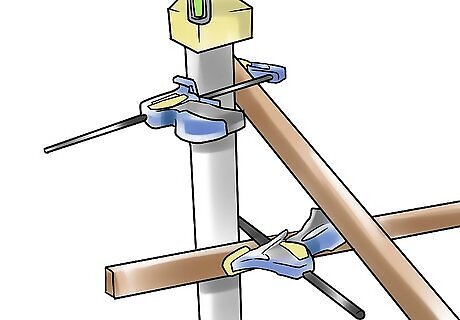

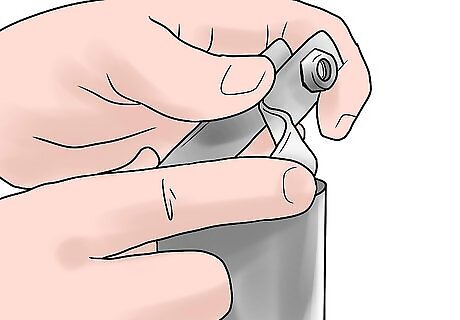

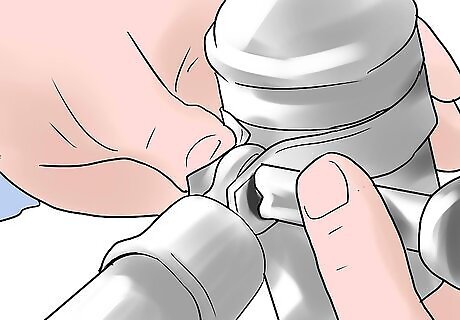

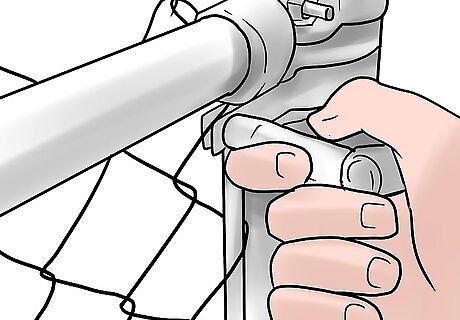

Feed the top rails through the loop caps. Cut off excess length with a pipe cutter or hacksaw. If the rails are too short, create longer runs by using rails with male-female coupling ends.

Insert the rail ends into the terminal rail caps. You may need to adjust the height of the rail caps to allow for the height of the chain link mesh, plus a 2 inch (5.1 cm) clearance at the bottom.

Tighten nuts and bolts. After checking your top rails and caps for proper fit and alignment, tighten all the hardware.

Add your dirt. Fill the line post holes with dirt, packing the dirt firmly around the holes.

Hang the Fence Mesh

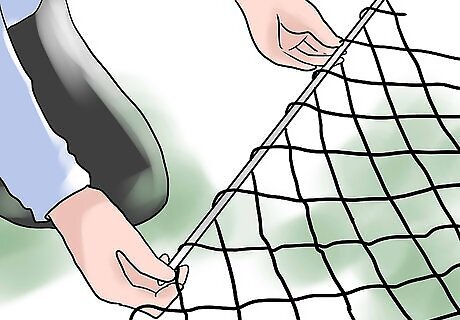

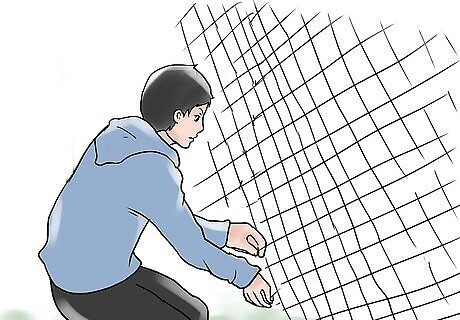

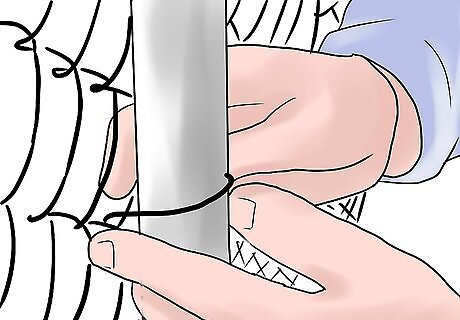

Slide a tension bar vertically through the starting end of the mesh roll. This will stiffen the mesh so that you can attach it to the fence posts and rails.

Bolt the tension bar to one of the terminal posts' tension bands. The mesh should overlap the rail by 1 to 2 inches (2.5 to 5.1 cm) and be 2 inches (5.1 cm) off the ground. You'll need someone to help you stand the mesh up to the end post and a socket wrench to turn the bolt.

Begin unrolling the mesh. Stand it up against the fence frame, taking out the slack as you go.

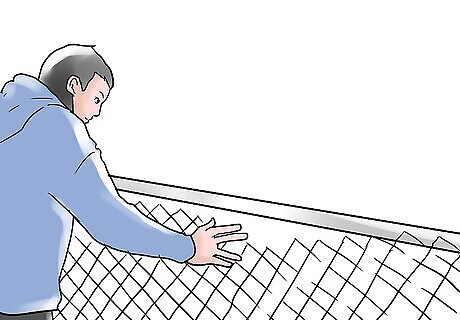

Loosely attach the mesh to the top rail. Use fence ties to hold it in place. Separate enough length from the roll to span the opening between the terminal posts.

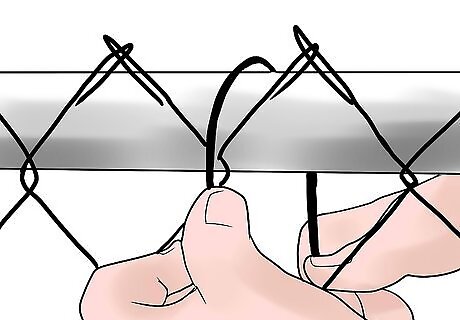

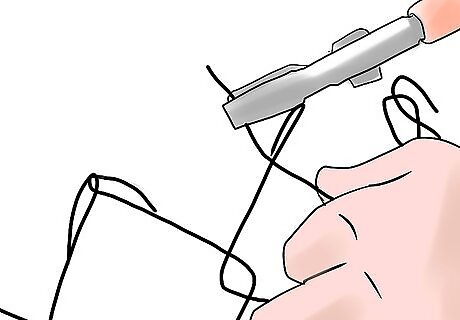

Splice sections together as needed. Using a single strand of wire removed from one end of the mesh, join two sections by corkscrewing the loose strand through the end links. A second strand may have to be removed to provide the correct line-up of "diamonds."

Remove excess mesh. Using pliers, untwist the top and bottom loops on one strand of wire where you want to separate the mesh. Work the freed strand out of the links until the two sections separate.

Stretching the Chain-link

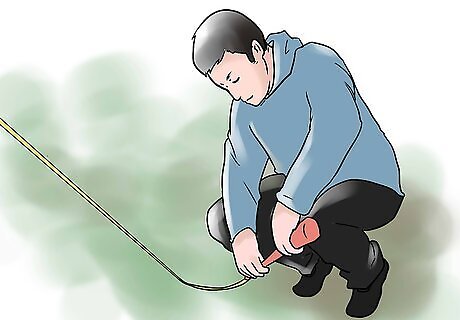

Pull the mesh taut with a fence puller. The stretching is necessary so the fence doesn't sag. Thread the fence puller's bar into an unattached section of mesh, a short distance from the far end post. Attach the fence puller's yoke to the pull bar and connect the other end of the puller to the far end post. Stretch the mesh with the fence puller until the mesh loops move less than a quarter-inch when squeezed by hand. If the mesh gets pulled out of shape during the tightening process, pull on it to reshape it.

Add a second tension bar. Run a second tension bar through the end of the mesh near the fence puller. This will permit attaching the stretched mesh to the far end post's tension bands.Thread the fence puller's bar into an unattached section of mesh, a short distance from the far end post.

Complete your fence with a tension bar. Terminate the mesh with a tension bar on the far end post's tension bands. Remove any new excess produced by stretching.

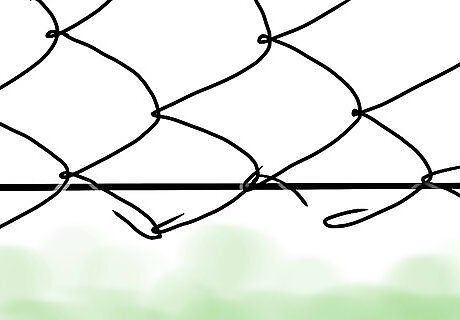

Tie the mesh to the rails with aluminum wire. Space your ties 24 inches (61.0 cm) apart along the top rail and 12 inches (30.5 cm) apart on each line post.

Add tension wire (optional). Thread tension wire through the bottom mesh loops. Tighten the tension wire around the end posts. Draw the wire tight and wrap it around itself next to the posts. Adding tension wire prevents animals from pushing in under the fence.

Comments

0 comment