views

Using a Sharpening Wheel

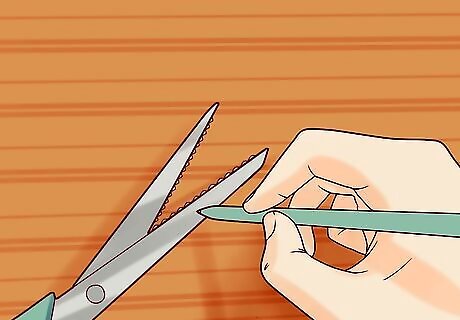

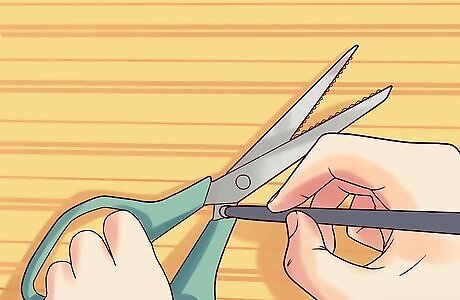

Examine the shears to find the lap line. A different kind of metal with a slightly different color is used for the cutting surface on most good-quality pair of pinking shears. Hold the blade and look at it from the side: there should be a shiny metal on the bottom side, a distinct line, and a darker matte grey metal on the cutting surface. If you don't see this, the shears need to be replaced. They've worn out over time and there's nothing left to sharpen. To sharpen pinking shears, you won't ever sharpen between the individual "teeth" on the blade, which would ruin the action of the shears and make it so they wouldn't cut properly. Instead, you want to sharpen along the flat edge of those teeth on the cutting surface, honing the teeth all the way from the "peak" at the top of each tooth to the "valley" at the bottom.

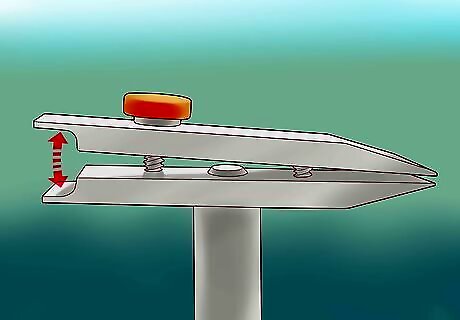

Set the proper angle of the clamp. The blades of most pinking shears have an angle of between 0 and 5 degrees, and some have a slightly negative angle at which you'll need to set the the clamp to sharpen them properly. Estimate the angle, or start at 0 and perform a scratch test to see if the clamp is set properly.> Secure the shears in the clamp so the flat side of the blade is perpendicular to the sharpening wheel.

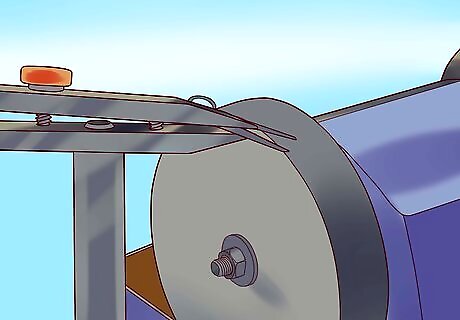

Do a scratch test. Use a permanent marker and blacken the flat blade side of the pinking shears you're going to sharpen. Make sure you darken all the way up to each peak and down to each valley. You don't need to color between them, just on the flat side you're going to sharpen. Rotate the sharpening wheel with your hand (you don't need to turn it on) to scratch the blade quickly on it to see if you've got the clamp set at the proper angle. You should see the blacking start to wear off on the blade, not lower on the silver side or too high on the peaks. Adjust the blade accordingly before you start sharpening.

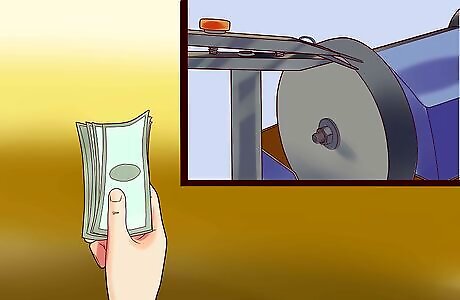

Grind the blacking off. When you've got the clamp set appropriately, turn on your machine and do a few passes with the blade. After three or four, turn it off again and examine your blade to make sure you're grinding evenly. If the black is removed, you're doing a good job. Do a few more passes, pausing every now and then to examine them, readjusting if necessary. Move the shears across the wheel in only one direction, applying even pressure and being extremely careful to keep your hands and clothes clear of the wheel. Wear safety protection and follow the manual instructions. When you've done the first, repeat the process for the second blade, maintaining the same angle.

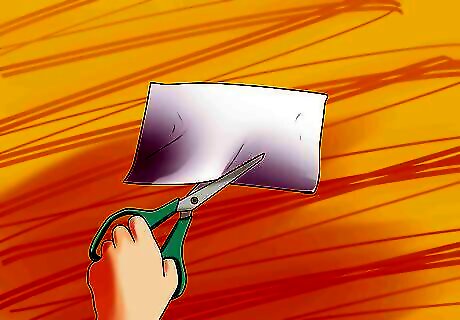

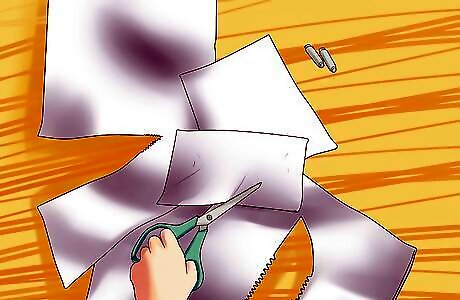

Test the shears. To make sure you've sharpened them evenly, cut some felt or other cloth. Properly sharpened pinking shears should cut with good action all the way down to the tip, and the teeth should pass between each other cleanly. If you're still having trouble, do a few passes on a honing wheel to get the burrs worked out and get the blade even and clean on the cut. Also check the other components of the shears to make sure they're well-oiled and smooth.

Maintaining Shears

Only use the shears on cloth. Trying to sharpen your shears by cutting into aluminum foil, Brillo pads, or sandpaper is ineffective and can end up damaging the blades by rounding them. Pinking shears need to be sharpened along the flat outside edge of each blade, not in between the valleys. Cutting aluminum or sandpaper rounds off the edges, making them duller and ruining the action, and does nothing to hone the flat side. Use your pinking shears on the appropriate materials and you shouldn't have problems. A roll of heavy-duty foil costs as much as $5 or $6 anyway and you risk ruining your shears at no savings. Get them done properly, either by investing in professional equipment or taking them to a pro. Using a regular whetstone is also not recommended. It's very difficult to get the edge of the recessed blade flush enough with the stone, and you risk ruining the edge by trying. Take them in instead or invest in the right equipment.

Consider getting your shears professionally sharpened. Getting pinking shears professionally sharpened at a fabric store costs $4-$6 dollars, less than the price of a new set, and much less than the cost of a rotary sharpening wheel ($300-$400). It's relatively cheap for the service, very fast, and you'll have the satisfaction of a well-maintained set of shears. If you're unsure where to get your shears sharpened, go into a fabric store and ask where they get their scissors sharpened. If not there, they should be able to recommend a place in your area that sharpens knives and shears.

Keep your shears well-oiled. A common complaint about pinking shears, especially old ones, is that they take a lot of hand-strength to use. Keep the connection screw well-oiled by adding a little dab of sewing machine oil every now and then when they get sticky. The sewing machine oil is specially made to not stain fabric, so it's a good choice if you're worried about getting your projects dirty. If you don't want to run out for new oil, you can try a dab of any regular cooking oil, coconut oil being especially effective.

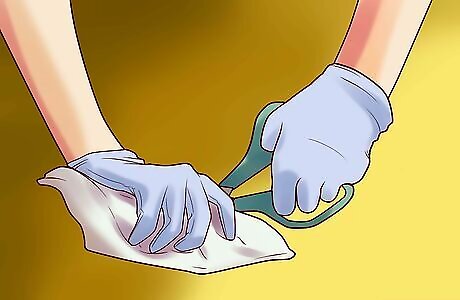

Avoid rust by keeping the shears clean and dry. You shouldn't regularly need to clean your shears, but if you get them dirty make sure you dry them immediately and thoroughly to avoid rusting. To remove rust, soak the blades for a few minutes in tiny amount of bleach (1 tsp.) in a bucket of water. Scrub them vigorously with a wire scouring pad or a Brillo and clean them with clear water. Dry the shears thoroughly and apply lubricating oil.

Comments

0 comment