views

- Put on a pair of safety glasses. Tap the middle of the screw with a center punch to make an indent.

- Use a drill bit narrower than the screw to make a shallow hole in the head.

- Turn the screw extractor counterclockwise into the hole to loosen and remove the screw.

Put on safety glasses.

Using a screw extractor requires drilling into the metal, which can create sharp metal shavings or even break the tool.Wear a pair of thick safety glasses made with polycarbonate lenses to protect your eyes while you work.

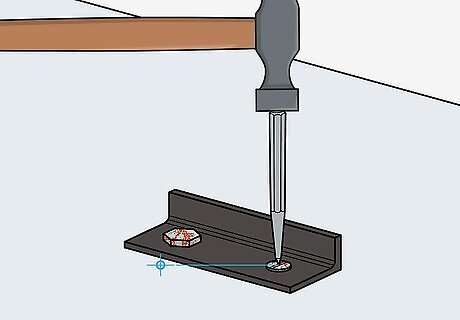

Tap the screw head with a center punch.

A center punch is a cylindrical piece of metal with a pointed end. Align the tip with the center of the screw head. Then, just tap the other end of the punch with a hammer to make a small indent. The indent will help prevent the drill bit or extractor from slipping away from the center of the screw.

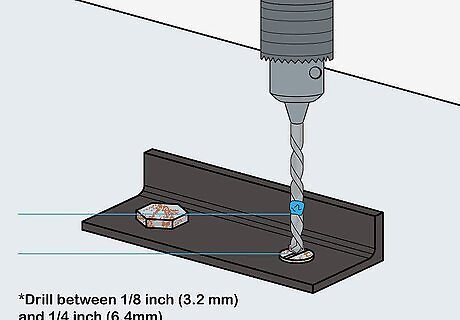

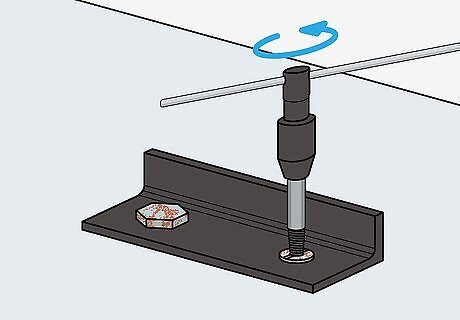

Drill out the center of the screw.

Choose a drill bit that’s slightly narrower than the screw head and attach it to your drill. Barry Zakar, a handyman, says that, “the screw extractor instructions will tell you what size bit to use for a given screw.” Then, place the drill bit in the divot on the center of the screw. Apply downward pressure so you drill straight down into the screw head by about ⁄8–⁄4 inch (0.32–0.64 cm).Instead of a separate bit, some screw extractors fit into your drill and have ends made to cut through the metal. Ryaan Tuttle, a handyman, notes, “you're going to use one end to the extractor bit and screw into the screw head and make it look like a little divot.”Pro Tip: Apply cutting oil to the screw to lubricate the metal so you spend less time drilling and create less wear and tear for your drill bit.

Turn the screw extractor counterclockwise.

Place the pointed threaded end of the screw extractor into the hole you just drilled. If your extractor came with a tap handle, attach it to the end of the extractor and turn it counterclockwise by hand. Alternatively, grip the extractor with a wrench to turn it.If your extractor is made to fit into a drill, Handyman Ryaan Tuttle says, “flip the extractor bit around and drill in reverse.”Keep twisting the extractor counterclockwise until you completely remove the screw.

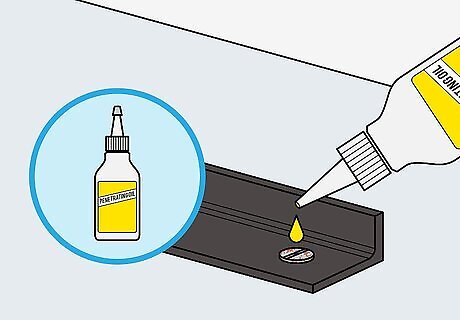

Apply penetrating oil for stubborn screws.

Penetrating oil loosens the screw, making it easier to remove. Add a drop of the oil onto the screw head and around the threads to help make the extractor work better. If the screw is attached to non-flammable materials such as metal, try heating it with a torch to expand the metal and make it easier to pull out.

Comments

0 comment