views

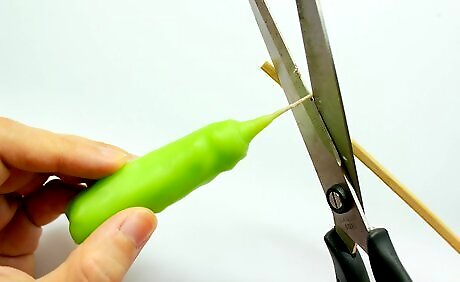

Cut the wicks to the length(s) desired. Make the wicks as long or as short as you would like. However, remember that the wick should be 4-6 inches (10-15 centimeters) longer than the candles you are making. A good wick is one that is less flexible than sewing thread, but more flexible than wire. Tie one end of the wick to a stick, such as a chopstick or a piece of dowel. This stick will be used to help you dip and to hang the candle from to dry.

Ready your dipping container. The container should be long enough to cover the candle size you are making. The more elongated the container, the less wax needed and therefore less waste.

Prepare the dipping area. Dipping can take some effort, so set aside a block of time to complete it. If the wax starts to solidify, you will need to melt it again as you go, so keep an eye on this. No matter how you have chosen to melt your wax, set up the dipping place carefully: Put newspaper down to protect the workspace from splashes. Put the container of melted wax onto a trivet. Place this on a sturdy work space at a height suitable for you to work around. Ensure that the area is free of obstacles, pets and small children.

Melt the wax. There are two methods for melting the wax. The first is to melt the wax in a double boiler over the saucepan. The second is to allow the wax to melt in a container of hot water set to one side. The choice of method depends on how many candles and how large the candles, along with how much wax you have to melt. If you are making a lot of candles, it will be easier to melt the candles using constant heat over a double boiler. Method 1: Place small chunks of wax into the double boiler. Allow to melt. See temperature notes in "Tips". Keep an eye on it. Also, see "Warnings". Method 2: Place the boiling water in a large container. Place the wax into the boiling water. Ensure that there is enough wax to reach the top of the container. Also make sure that the container is sitting one a safe place away from heat sources. Allow the wax to melt. You can stir it if needed.

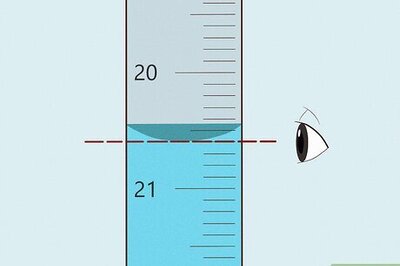

Commence dipping the wicks. Tighten the wick until it is straight. Lower the taper into the melted wax. Cover it with wax. Holding on to the top of the wick by its stick, quickly dip it into and out of the melted wax. This must be done rapidly up and down, or the wax will slip off the string. The most effective method to ensure that the wax stays on, is to set aside each candle when there is a thin layer and then to return and dip some more when you reach the last candle and proceed to dip all of the candles again. Gently blow on the string after each dip. This helps it to position for cooling in place. Note that initially the wax will coat the taper and slowly a taper candle will begin to form. Keep dipping patiently to layer on the wax. Reheat wax if needed. Repeat this process as many times as needed to form a width and shape of taper candle that you are seeking.

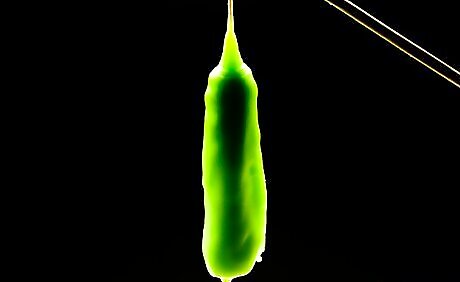

Allow the candles to dry. Lay out the taper candles on a "drying rack". Use a small cardboard box and lay the sticks over this, with the candles dangling down. Do not let the candles touch the ground - suspend them in the air. The candles are done when they are hard to the touch.

Trim the wick at both ends of the candle. At the thinner end of the finished taper, create a small wick for lighting of about 1/2" (1.2 centimeters). At the thicker end, cut the wick as close as you can to the finisher taper. Trim any wax formations that do not form part of the taper candle shape.

Finished.

Comments

0 comment