views

X

Research source

and evaporation of your ethanol fuel blend, whether you are storing a few gallons for personal use or large quantities for commercial purposes.

Following Basic Storage Guidelines

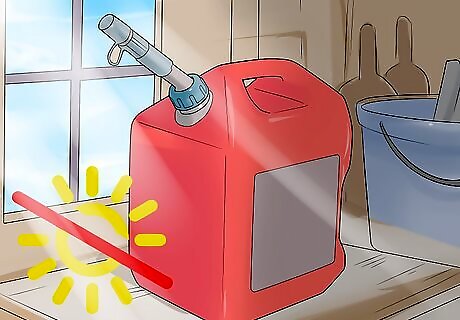

Keep your ethanol fuel blend out of direct sunlight. This will reduce the potential for evaporation by helping to maintain a stable and cool temperature. If possible, try storing your ethanol in a climate-controlled, cool environment. A shed, garage or workshop is a good spot to store fuel, as long as it does not get extremely hot or cold throughout the course of the year.

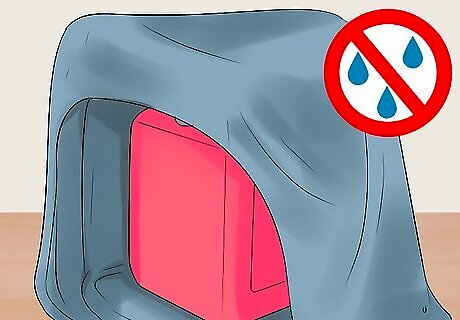

Store ethanol somewhere dry. Ethanol is hygroscopic, which means that it pulls in moisture from the air. Unfortunately, if water mixes with your ethanol fuel blend, it will render it useless. To avoid water contamination, make sure that your storage tanks are sealed tight. It's also a good idea to protect the tanks with a waterproof tarp if they're stored somewhere like a shed where they could be exposed to moisture.

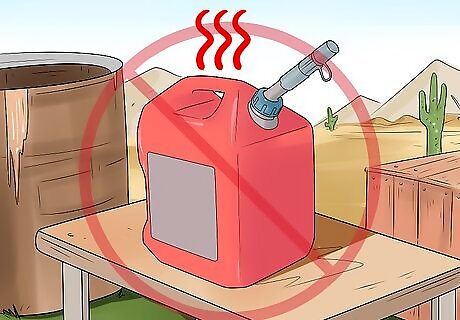

Avoid storing ethanol where temperatures will vary greatly. A climate-controlled room where the temperature is cool and stable is ideal, but a garage or storage cabinet is a more realistic and feasible option. You should not store your ethanol unprotected outside where it is prone to shifting temperatures and moisture. Temperature variance can cause condensation to collect inside your storage tank if it is not properly sealed. It only takes a 7-degree temperature change for condensation to form on the walls of a fuel tank, and this moisture can ruin your fuel. You can protect your fuel tanks from internal condensation by making sure they are properly sealed without ventilation to the outside environment.

Maintain full levels of fuel in your storage tanks. Having a full tank minimizes the surface area of the tank wall that could potentially collect moisture from condensation. You can combine partially-full tanks of the same ethanol blends to avoid water contamination by condensation. By the same principle, it is wise to drain the fuel tanks of vehicles that burn ethanol blends when going into storage to avoid condensation.

Mark tanks that contain different ethanol fuel blends. You never want to mix different concentrations. The chemical reaction can separate out water and make your fuel unusable. Clearly mark your storage tanks, and if you plan to add a different ethanol concentration than what is on a tank's label, be sure to thoroughly clean out and dry the tank beforehand.

Storing Small Amounts of Ethanol

Choose a steel, UL-listed fiberglass or HDPE storage container. Ethanol is corrosive to many common metals and plastics, such as aluminum, zinc, copper, polymers, rubbers, elastomers, glues and sealants that have a dissolved alcohol base. Be sure your storage container is resistant to these effects. For personal storage needs, HDPE jerry cans are one of the most popular options. They can be found online and in hardware and automotive stores.

Clean your tank before inputting your ethanol fuel. Thoroughly rinse the tank out with soap and water and sit it out in the sun with the cap open to dry. Allow a few days for this to happen to be certain all water is gone from the inside of the tank. There are also oil-removing industrial soaps available in your local hardware, automotive or department store.

Keep storage tanks away from fire, sparks, or daily foot traffic. Ethanol is extremely flammable and you should show great care with where and how you store it. Be aware that ethanol is toxic in larger doses and when combined with other fuels and should be kept away from children and animals. Spilt ethanol can also pose an environmental hazard, especially if it makes its way into streams and rivers.

Storing Large Amounts of Ethanol

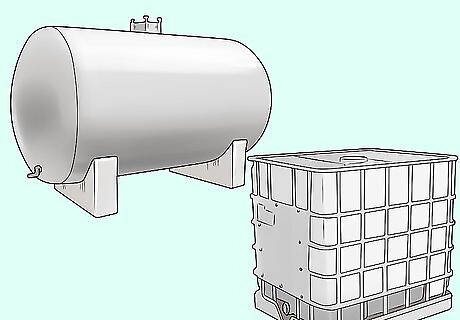

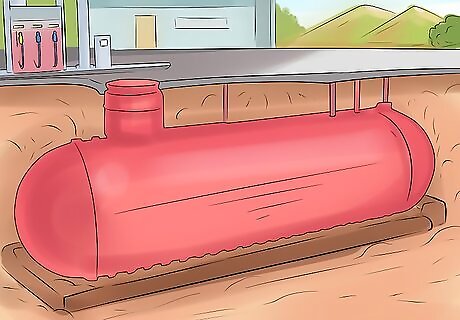

Choose a steel, UL-listed fiberglass or HDPE storage container. All steel commercial tanks have the advantage of being compatible with ethanol blends up to E100. Fiberglass tanks can vary with their ethanol concentration compatibility, but there are options available for more corrosive blends like E85 fuels. Recommended tank materials include double-walled steel or UL-listed fiberglass. UL is the primary safety certification laboratory for the global refueling equipment industry. There are a number of retailers for large commercial tanks, such as ZCL | Xerxes, The Southern Company of North Little Rock and western Equipment. There is information on their websites about how to order one of their large ethanol storage tanks. Typically these tanks are stored underground at commercial gas stations, but above-ground tanks are also available.

Ensure all components of your storage system are compatible with your stored fuel. Higher concentrations of ethanol are more corrosive, so if you are storing fuels that are higher than E10, you'll want to make sure that all the components of your storage system are equipped to handle regular exposure to these types of ethanol fuel blends. This is especially important for Underground Storage Tanks (UST), which are the most commonly used at gas stations. These tanks are part of a system that is comprised of many different parts, all of which must be composed of proper materials that can stand up to the corrosive properties of ethanol.

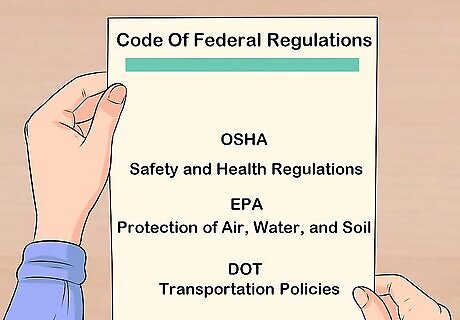

Comply with federal regulations regarding ethanol storage. There are specific protocols and regulations that must be followed for storage of ethanol concentrations above E10. Be sure to read the EPA, OSHA and Department of Energy codes yourself for more detailed information on storing commercial quantities of ethanol. These codes are available for view online at the agency websites. Federal regulation requires clear labeling of pumps for different ethanol blends. Labeling of your fuel pumps must be the official EPA labels. This is done to make it apparent to consumers which pumps are for which ethanol blends. You must attain proper certifications and inspections for storage of concentrations above E10. If switching a storage tank to a blend greater than E10, notify your implementing agency, usually a state office, 30 days prior to the switch. You must maintain records that demonstrate compatibility of your equipment by an independent certifying agency, such as a nationally recognized testing laboratory or the manufacturer for use with the fuel stored.

Check with local and state authorities for information about local environmental codes. Inquire about any additional regulations or requirements that are specific to your state or municipality for storing ethanol blends above E10. Some states have more stringent environmental codes that will result in you needing to attain additional certifications and licenses. Contact your city's or county's environmental health and safety office to learn more about local codes.

Apply the same basic storage guidelines to your large tank. Always be aware of the threat of water contamination, and aim to keep your tank in a stable and cool environment. Aim to refill your tanks to full capacity as often as is logistically reasonable.

Clean your tank periodically. Always clean your tank if you are switching between different concentration ethanol blends. It is also good practice to regularly clean your large storage tanks to remove particulates, rust, sludge and other wastes that may be present or accumulate over time. There are a number of common cleaning methods. Optic sweep: This method uses a controllable camera and probe to remove sludge, rust particles, water and other contaminants without tank downtime. Steam cleaning: A person physically enters the tank and steam cleans it. Proper dry time must be allowed. Filter agitator: An agitating device is lowered into the tank and the fuel is circulated to dislodge any contaminants or debris. A filtration system removes suspended debris. Chemical solvents: Solvents are used to remove scale and debris. Liquid and debris are then pumped from the tank and disposed of.

Comments

0 comment